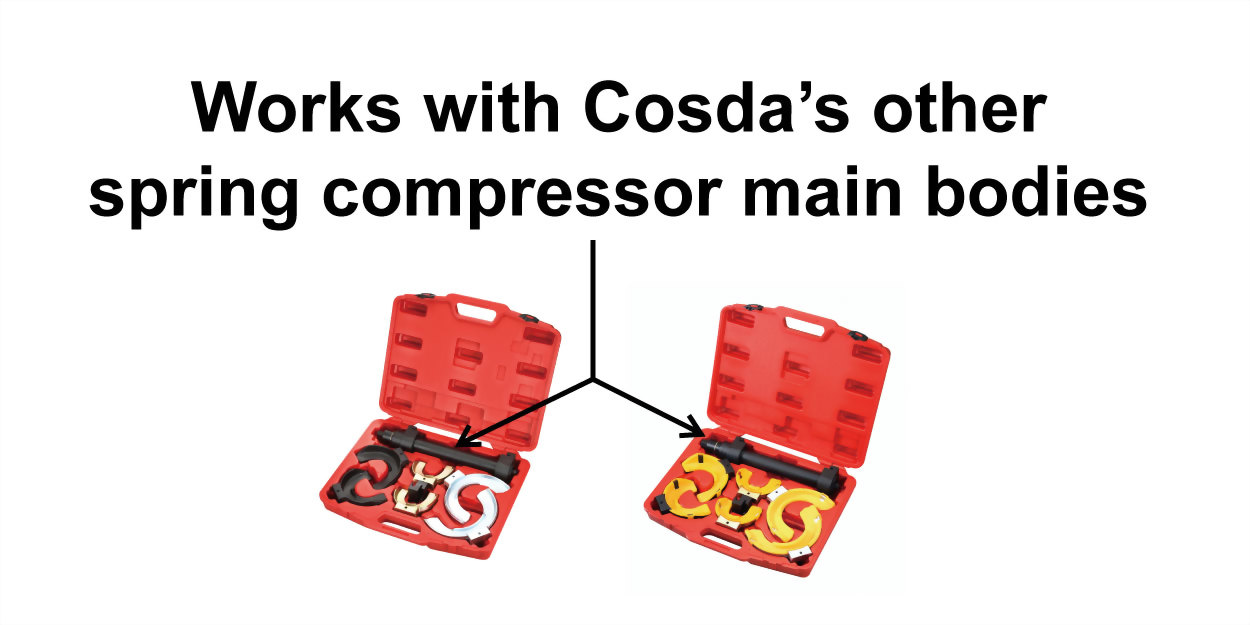

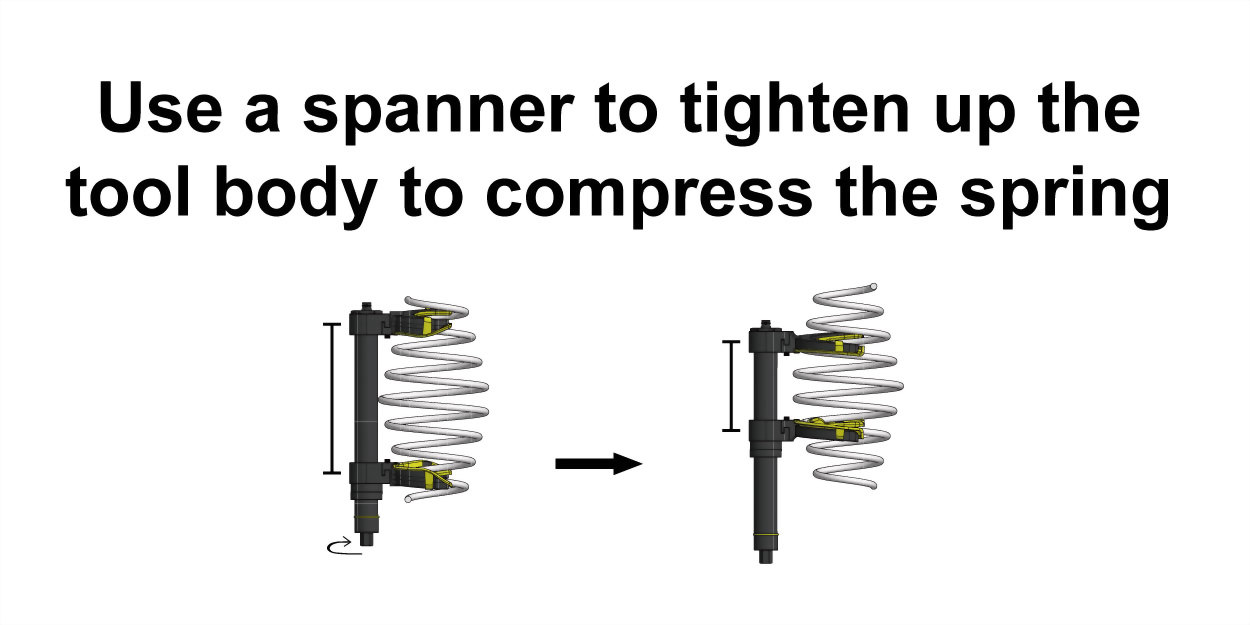

Left-hand Jaw Pairs for MacPherson Spring Compressors

• Includes two pairs of C jaws for fitting various sizes (Spring compressor tool is not included)

• Jaw covers are RoHS certified, containing no SVHC materials

• Small C jaws fit to Honda CR-V MK2, 3, 4 front right springs

• Big C jaws fit to Nissan Qashqai MK1 & 2, and Renault Kadjar front left springs

Shock absorber coil springs can be wound in either a left-hand (counterclockwise) or right-hand (clockwise) direction based on several engineering considerations. Here are some reasons why some coil springs are designed with a left-hand turn:

1. Space Constraints and Design Symmetry: In certain suspension designs, a left-turn spring might better fit the available space or align more symmetrically with the rest of the vehicle’s components. For instance, in a vehicle's suspension system, if one side uses a right-hand coil spring, the other side might use a left-hand coil spring to maintain balance and symmetry.

2. Load Distribution: The direction of the coil winding can affect how the spring distributes load and resists forces. In some cases, a left-turn spring might be chosen to optimize the distribution of forces within the suspension system, ensuring better handling or more even wear.

3. Manufacturing Requirements: Some springs are designed with a left-hand turn based on the manufacturing process or to match other components that also have a left-hand thread or winding.

4. Torsional Effects: The direction of the coil can influence the torsional characteristics of the spring. A left-turn spring might be used to counteract or complement other torsional forces in the suspension system, contributing to the overall stability and performance of the vehicle.

5. Compatibility with Other Components: Certain suspension systems or shock absorbers might be designed to work specifically with left-turn springs due to the way they interface with other parts, such as the spring seats or strut mounts.

Ultimately, the choice between left-turn and right-turn coil springs is a result of engineering considerations that aim to optimize the vehicle's performance, durability, and safety.

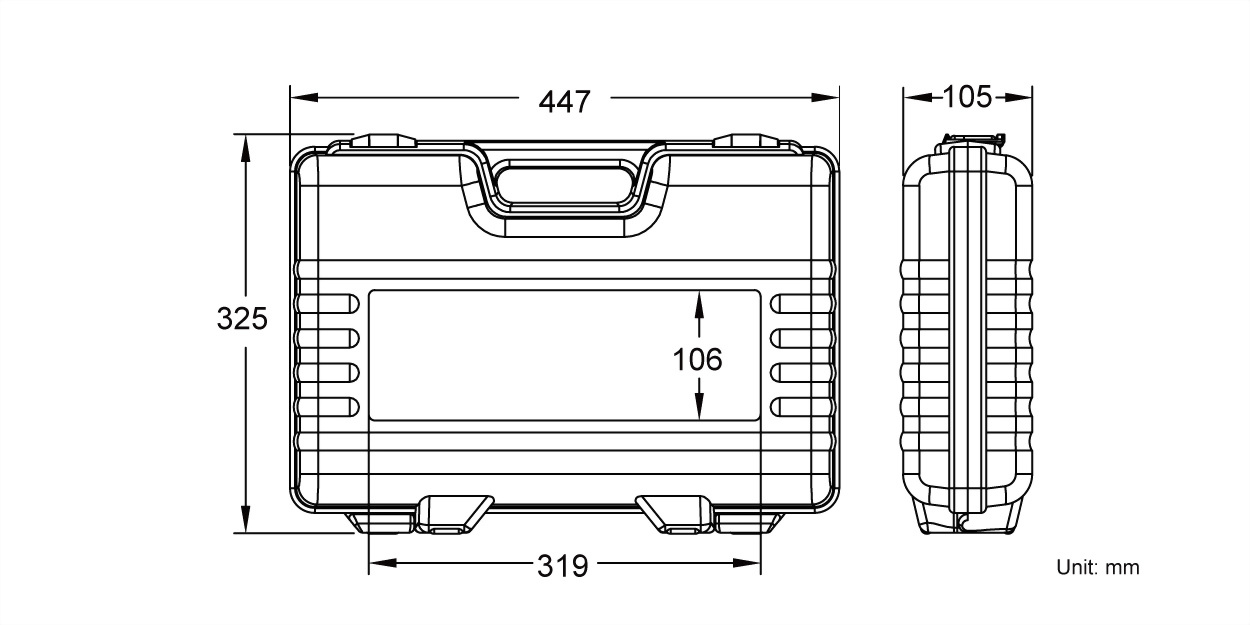

| Package | Blow molded case (black) | |

| Packing | 2 sets in a master carton | |

| Weight per set | 7.1 kg | 15.5 lbs |

| Net weight per carton | 15.6 kg | 34.4 lbs |

| Gross weight per carton | 16.6 kg | 36.5 lbs |

| Size per set | 44.7 × 32.5 × 10.7 cm | 17.6 × 12.8 × 4.2 inch |

| Size per carton | 45.8 × 35.2 × 23.0 cm | 18.0 × 13.8 × 9.0 inch |

| Volume per carton | 0.037 CBM | 1.3 CUFT |

| Case label size | 31.9 × 10.6 cm | 12.6 × 4.2 inch |

| Suggested HS code |

82055990909 |

| MOQ with laser marking | 10 sets |

| MOQ without laser marking | 2 sets |

| Laser marking cost | + TWD 5 on each jaw |

| Not for sale in | UK (exclusivity) |