Turnbuckles for Shock Absorber Caps (39 pcs)

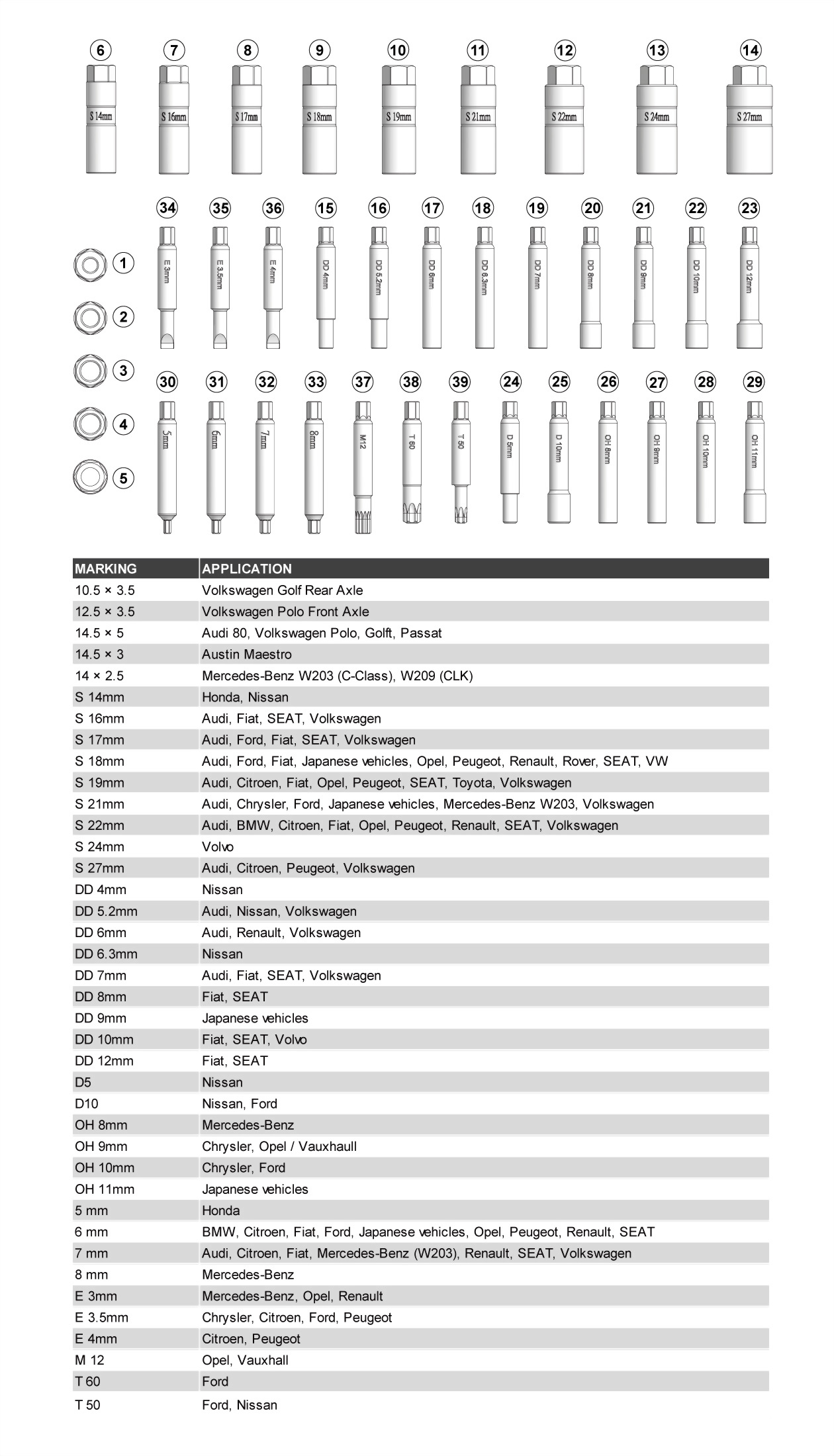

• Includes a large variety of sockets with various sizes

• Provided with bits with special sizes

• DO NOT use with an air/impact wrench

This bulky but versatile tool set will be super helpful when your auto service shop always work on suspension services. Once you jack off the car, take the wheels off, remove the anti-sway bar, you can unscrew the fasteners on top to take the MacPherson strut, or the front strut, off the car. The central strut is the place that usually gets problematic. The rubber boot outside the strut, or inside the coil spring, has the function to get the dirt and debris away from the strut. But as time goes by, the rubber boot might break, and the sand or some other small particles will be taken into the strut and cause the gaps between each part of the strut to wear off, and finally resulting the hydraulic fluid inside the strut leak. Usually when you take a look at the strut or the surrounding areas and find that there are stains or fluid spills, that means the strut needs to be replaced.

Replacing the strut is very easy but there are some places we need to pay attention to. The first thing is to use a high quality spring compressor tool. You may use the professional tool has is screwed on the wall, or use a sturdy spring compressor that can be attached to the spring from the side. Please do not use any flimsy or tricky-looking spring compressors because the force that the spring bounces back if the spring compressor fails can be dangerous, or even deadly. And you definitely don't want this happens to you. Once the coil spring is clamped down by a proper spring compressor tool, so that the gaps between each coil is smaller, you can see the top lid of the MacPherson strut becomes nice and loose and wiggling it around, and it's time to detach the top lid off the strut and the coil spring.

The top lid uses an interesting way to make itself hold in place. On top of the fastening nut you will see that there is a protruding part, there might be an internal hex, spline, or some other strange shapes, or external. That protruding part is part of the central shaft but the problem is when you turn, the top lid turns accordingly. So what we have to do is to first find a bit from this tool set which the shape of the bit fits perfectly to the top of the strut, and then second, use the hex socket, which is located on the upper lane of the tool set, to fit with the external hex on the top lid. The external hex holds the strut and the top lid together. Fit the two tools on, and turn the bit while hold the socket still, or to counter loose the two part, and then the central strut will be detached from the top lid.

This tool set includes hex sockets with sizes from 14 mm to 27 mm, and the bits come in a wide variety of shapes and sizes. With this tool set, you are able to service the shock absorbers from a wide range of car brands and models. This tool set is designed and manufactured by Cosda Manufacturing Company, a leading auto special tool manufacturer that provides high quality, low return rate, and private branding services to the major tool brands around the world. If you are looking for manufacturers that can help you turn your ideas into actual product, or the manufacturer is able to put your logo on their products, Cosda is definitely the one you have been looking for. Please feel free to contact us for more information.

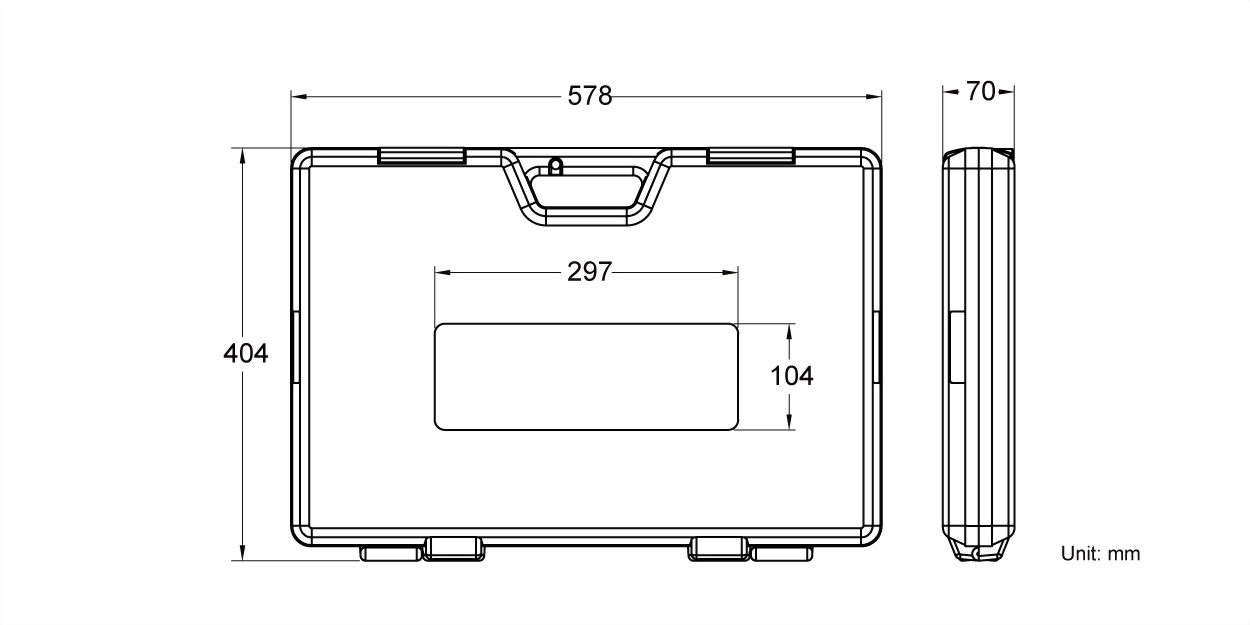

| Package | Blow molded case (black) | |

| Packing | 3 sets in a master carton | |

| Weight per set | 6.3 kg | 13.9 lbs |

| Net weight per carton | 19.0 kg | 41.8 lbs |

| Gross weight per carton | 20.0 kg | 44.0 lbs |

| Size per set | 57.8 × 40.4 × 7.0 cm | 22.7 × 15.9 × 2.7 in |

| Size per carton | 59.0 × 42.0 × 23.0 cm | 23.2 × 16.5 × 9.0 in |

| Volume per carton | 0.05 CBM | 2.1 CUFT |

| Case label size | 29.7 × 10.4 cm | 11.7 × 4.1 in |

| No. | Image | Cosda No. | Description | |||||

|---|---|---|---|---|---|---|---|---|

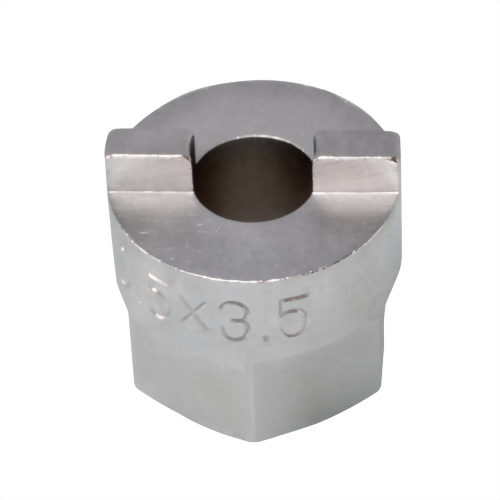

| 1 |  |

SD-1022-01 | Turnbuckle M10.5 × 3.5 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

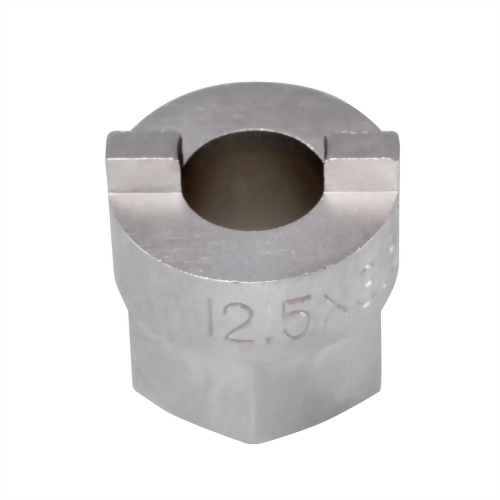

| 2 |  |

SD-1022-02 | Turnbuckle M12.5 × 3.5 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 3 |  |

SD-1022-03 | Turnbuckle M14.5 × 5.0 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 4 |  |

SD-1022-04 | Turnbuckle M14.5 × 3.0 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 5 |  |

SD-1022-05 | Turnbuckle M14.0 × 2.5 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 6 |  |

SD-1022-14 | Socket Hex 14 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 7 |  |

SD-1022-16 | Socket Hex 16 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 8 |  |

SD-1022-17 | Socket Hex 17 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 9 |  |

SD-1022-18 | Socket Hex 18 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 10 |  |

SD-1022-19 | Socket Hex 19 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 11 |  |

SD-1022-21 | Socket Hex 21 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 12 |  |

SD-1022-22 | Socket Hex 22 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 13 |  |

SD-1022-24 | Socket Hex 24 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 14 |  |

SD-1022-27 | Socket Hex 27 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 15 |  |

SD-1022-34 | Bit DD 4.0 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 16 |  |

SD-1022-35 | Bit DD 5.2 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 17 |  |

SD-1022-36 | Bit DD 6.0 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 18 |  |

SD-1022-37 | Bit DD 6.3 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 19 |  |

SD-1022-38 | Bit DD 7.0 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 20 |  |

SD-1022-39 | Bit DD 8.0 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 21 |  |

SD-1022-40 | Bit DD 9.0 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 22 |  |

SD-1022-41 | Bit DD 10 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 23 |  |

SD-1022-42 | Bit DD 12 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 24 |  |

SD-1022-45 | Bit D 5 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 25 |  |

SD-1022-50 | Bit D 10 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 26 |  |

SD-1022-58 | Bit OH 8 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 27 |  |

SD-1022-59 | Bit OH 9 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 28 |  |

SD-1022-60 | Bit OH 10 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 29 |  |

SD-1022-61 | Bit OH 11 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 30 |  |

SD-1022-65 | Bit Hex 5 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 31 |  |

SD-1022-66 | Bit Hex 6 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 32 |  |

SD-1022-67 | Bit Hex 7 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 33 |  |

SD-1022-68 | Bit Hex 8 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 34 |  |

SD-1022-73 | Bit E 3.0 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 35 |  |

SD-1022-74 | Bit E 3.5 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 36 |  |

SD-1022-75 | Bit E 4.0 mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 37 |  |

SD-1022-81 | Bit M12 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 38 |  |

SD-1022-82 | Bit T60 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 39 |  |

SD-1022-83 | Bit T50 | More |

||||

|

- Specifications

|

||||||||

| Suggested HS code |

82055990909 |

| MOQ with laser marking | 18 sets |

| MOQ without laser marking | 3 sets |

| Laser marking cost | + TWD 3 each piece |