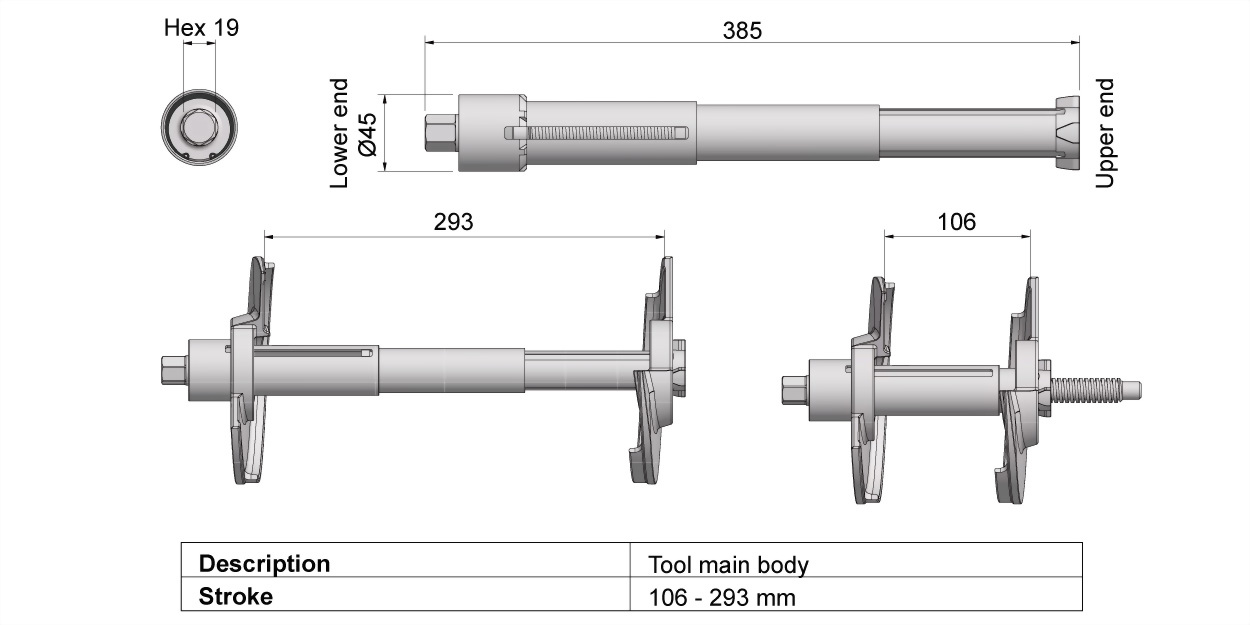

Internal Coil Spring Compressor Ø75 - 155 mm

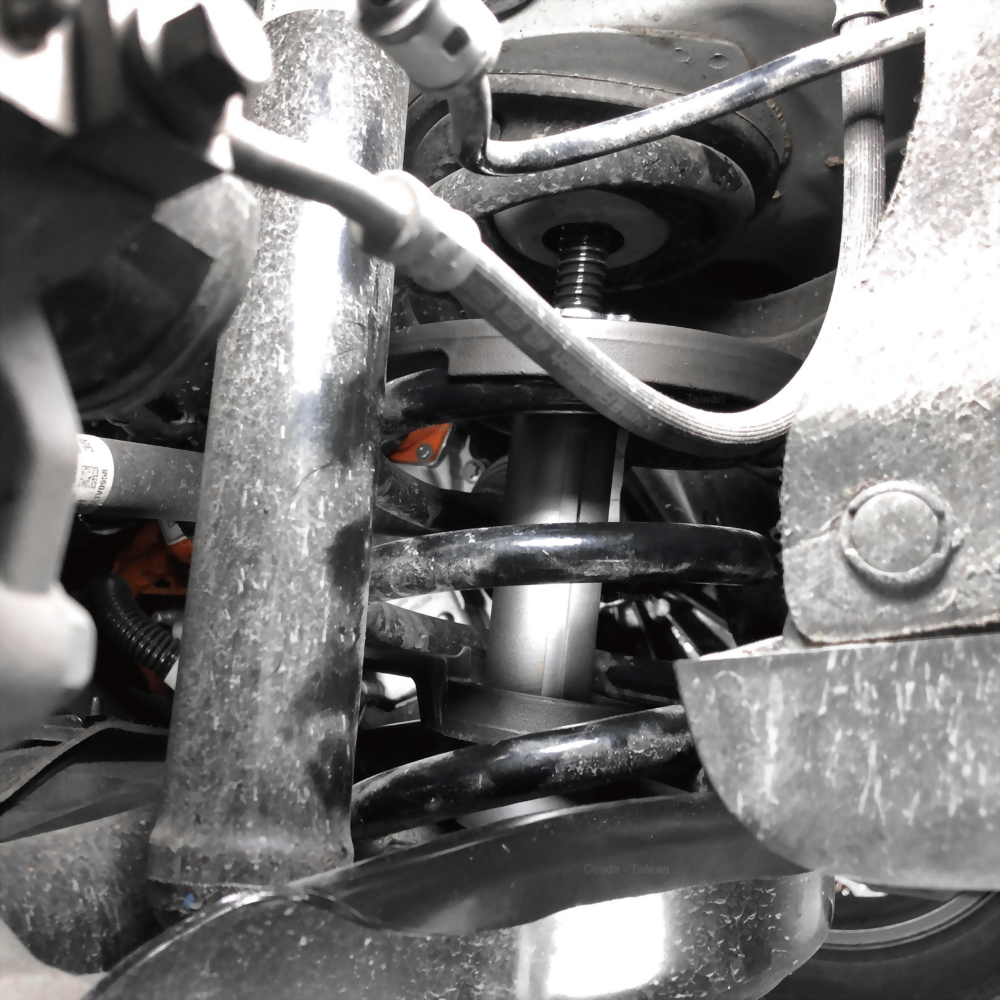

• Special pins on tool body to mesh with grooves on discs to create a secure connection (see illustration on the right)

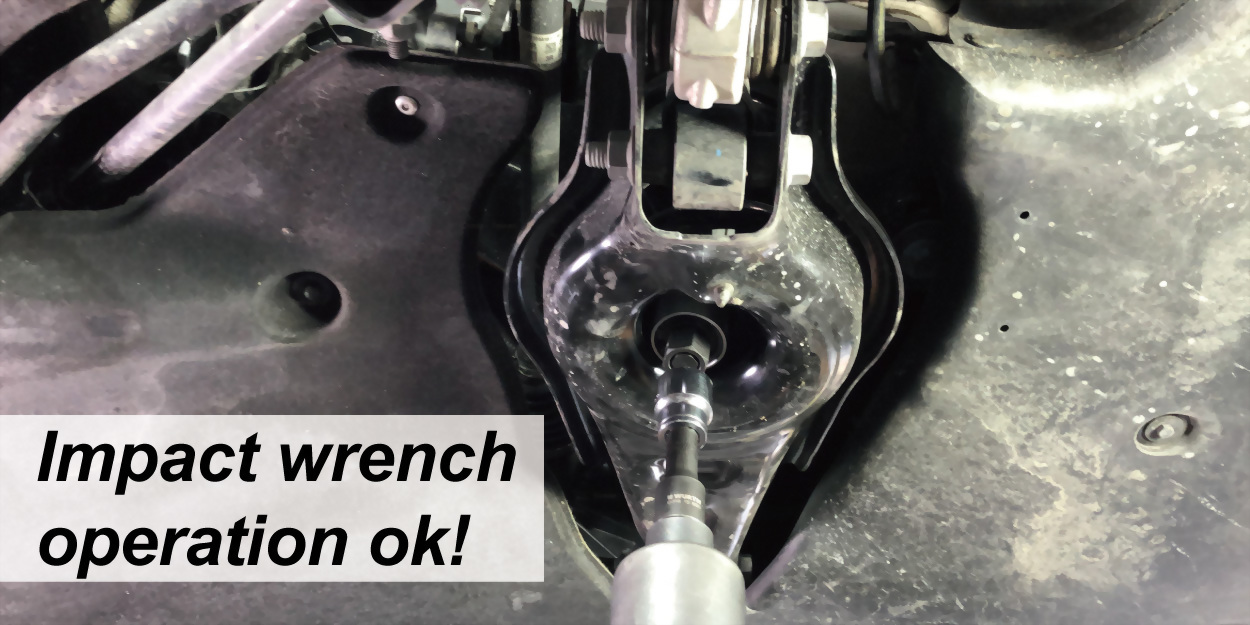

• Can be operated with an air/impact wrench

• Provided with product liablity insurance

• Suitable for

- Audi A4, A6

- BMW 3 Series E46, X3 E83, X6 E71, E72, Z3 E36

- Citroen Berlingo, C8, Dispatch

- Fiat Bravo, Croma, Punto, Scudo, Ulysse

- Ford Galaxy, Maverick, Mondeo

- Hyundai Getz, Santa Fe

- Mercedes-Benz A-Class W169, W176, B-Class W245

- Nissan Cube, Leaf, Micra, Murano, Versa

- Opel Astra G/H/J, Corsa B/C, Insignia, Zafira A/B

- Peugeot 207, 807

- Renault Clio, Espace, Laguna, Thalia

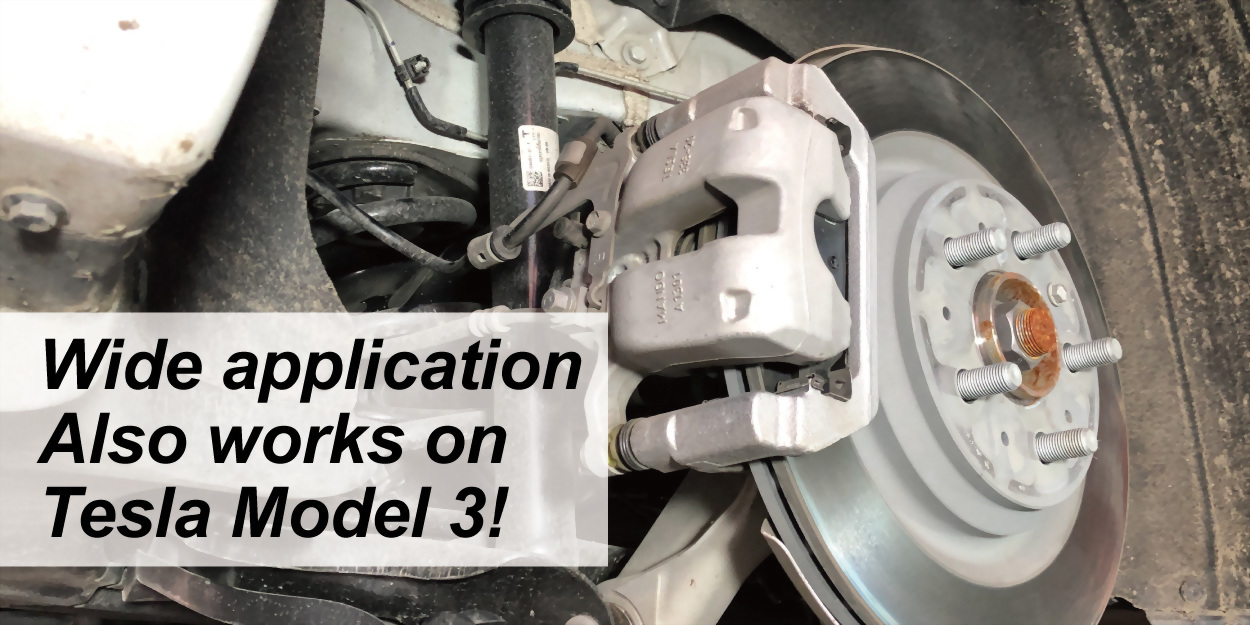

- Tesla Model 3

- Volvo C70, S80, V60, V70, XC60, XC70

What type of rear shock absorber does Tesla Model 3 use?

The Tesla Model 3 uses a multi-link rear suspension setup, which typically includes monotube shock absorbers.

Key Features of the Rear Shock Absorbers in Tesla Model 3:

1. Monotube Design:

- The shock absorbers in the rear of the Tesla Model 3 are generally monotube, which means they have a single tube containing both the hydraulic fluid and the gas chamber. This design provides better heat dissipation, consistent damping performance, and is often used in performance-oriented vehicles.

2. Adaptive Dampers (Optional):

- In some variants, particularly in the Performance models, the Model 3 may come with adaptive dampers. These adjust the damping force in real-time based on driving conditions and inputs, providing a balance between comfort and handling.

3. Integrated with Multi-Link Suspension:

- The rear multi-link suspension system allows for independent movement of the wheels, which helps improve ride quality and handling. The shock absorbers play a crucial role in dampening the motion of the suspension, contributing to the vehicle's overall stability and comfort.

4. Focus on Comfort and Performance:

- Tesla has engineered the Model 3's suspension, including its shock absorbers, to offer a smooth ride while maintaining sporty handling characteristics. The rear shock absorbers are tuned to manage the weight distribution and dynamics of the electric vehicle.

The combination of a multi-link suspension with monotube shock absorbers helps the Tesla Model 3 achieve its renowned balance of comfort, handling, and performance.

How can we maintain this type of multi-link rear suspension?

Maintaining the multi-link rear suspension of a vehicle like the Tesla Model 3 is crucial for ensuring long-term performance, handling, and safety. Here’s a comprehensive guide on how to properly maintain a multi-link rear suspension system:

1. Regular Inspection

- Visual Checks: Regularly inspect the suspension components, including the control arms, bushings, ball joints, and shock absorbers. Look for signs of wear, damage, or corrosion.

- Listen for Noises: Pay attention to any unusual noises like clunking, squeaking, or rattling when driving, especially over bumps or during turns. These can indicate worn or damaged suspension components.

2. Check and Replace Bushings

- Inspect Bushings: The bushings in a multi-link suspension are critical for absorbing shocks and reducing vibrations. Over time, they can wear out or crack, leading to increased noise and reduced suspension performance.

- Replacement: If bushings show signs of wear, such as cracks, tears, or excessive play, they should be replaced. Polyurethane bushings last longer but might be stiffer, affecting ride comfort, while rubber bushings offer a smoother ride but may wear out faster.

3. Monitor and Maintain Shock Absorbers

- Check for Leaks: Regularly inspect the shock absorbers for any signs of oil leakage. A leaking shock absorber will not perform efficiently and should be replaced.

- Test Performance: If the vehicle feels bouncy or doesn’t stabilize quickly after going over bumps, the shock absorbers might be worn out and need replacement.

4. Alignment and Wheel Balance

- Regular Alignment Checks: The multi-link suspension can affect wheel alignment. Misalignment can cause uneven tire wear, reduced handling performance, and strain on suspension components. Have the alignment checked regularly, especially if you notice the vehicle pulling to one side.

- Wheel Balancing: Unbalanced wheels can lead to vibrations that put stress on the suspension components. Ensure that your wheels are properly balanced, particularly after replacing tires.

5. Tire Maintenance

- Regular Rotation: Rotate your tires regularly to ensure even wear, which helps maintain consistent handling and reduces stress on the suspension.

- Check Tire Pressure: Maintaining proper tire pressure is essential for optimal suspension performance. Under-inflated or over-inflated tires can negatively impact handling and wear out suspension components faster.

6. Clean and Protect Suspension Components

- Remove Dirt and Debris: Regularly clean the suspension components to remove dirt, grime, and road salt that can cause corrosion and wear.

- Rust Prevention: Apply anti-rust treatments to the suspension components if you live in an area where road salt or moisture is a concern.

7. Lubrication

- Ball Joints and Bushings: Some suspension components, like ball joints and certain types of bushings, may require periodic lubrication. Use the appropriate lubricant as recommended by the manufacturer to ensure smooth operation and prevent wear.

8. Replace Worn Components Promptly

- Timely Repairs: If any component of the suspension shows signs of wear or damage, it’s important to replace it promptly. Ignoring worn components can lead to more extensive damage to the suspension system and affect overall vehicle safety.

9. Professional Inspection and Servicing

- Regular Professional Check-ups: Even if you perform regular inspections yourself, it’s wise to have the suspension system professionally inspected at regular intervals, especially during routine maintenance services like oil changes.

- Advanced Diagnostics: A professional mechanic can use diagnostic tools to check for issues that might not be visible during a basic inspection, such as worn internal components of the shock absorbers or misalignment, and using Cosda's SD-1001T is able to help the mechanic to work efficiently.

10. Driving Habits

- Avoid Harsh Driving: Aggressive driving, such as hard cornering, abrupt braking, or frequent driving on rough roads, can accelerate wear on the suspension components. Adopting smoother driving habits can extend the life of your suspension.

- Load Management: Avoid overloading the vehicle, as excessive weight can strain the suspension system, leading to premature wear.

Summary:

Maintaining a multi-link rear suspension, like the one in the Tesla Model 3, requires regular inspections, timely replacement of worn components, proper alignment, and careful driving habits. By keeping up with these maintenance tasks, you can ensure that your vehicle continues to provide a smooth, stable ride with optimal handling.

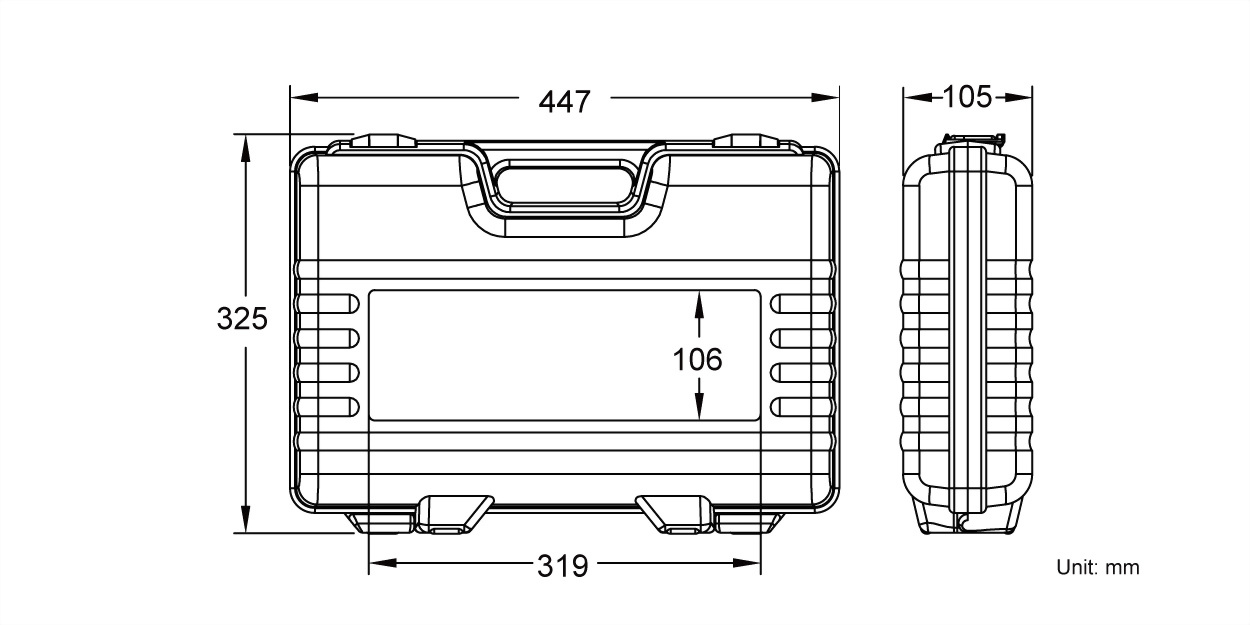

| Package | Blow molded case (black) | |

| Packing | 4 sets in a master carton | |

| Weight per set | 5.5 kg | 12.1 lbs |

| Net weight per carton | 22.0 kg | 48.4 lbs |

| Gross weight per carton | 23.0 kg | 50.6 lbs |

| Size per set | 44.7 × 32.5 × 10.7 cm | 17.6 × 12.8 × 4.2 inch |

| Size per carton | 45.8 × 44.5 × 35.2 cm | 18.0 × 17.5 × 13.9 inch |

| Volume per carton | 0.072 CBM | 2.6 CUFT |

| Sticker size | 31.9 × 10.6 cm | 12.6 × 4.2 inch |

| Suggested HS Code |

82055990909 |

| MOQ with laser marking | 8 sets |

| MOQ without laser marking | 4 sets |

| Laser marking cost | + TWD 3 on body or on discs |