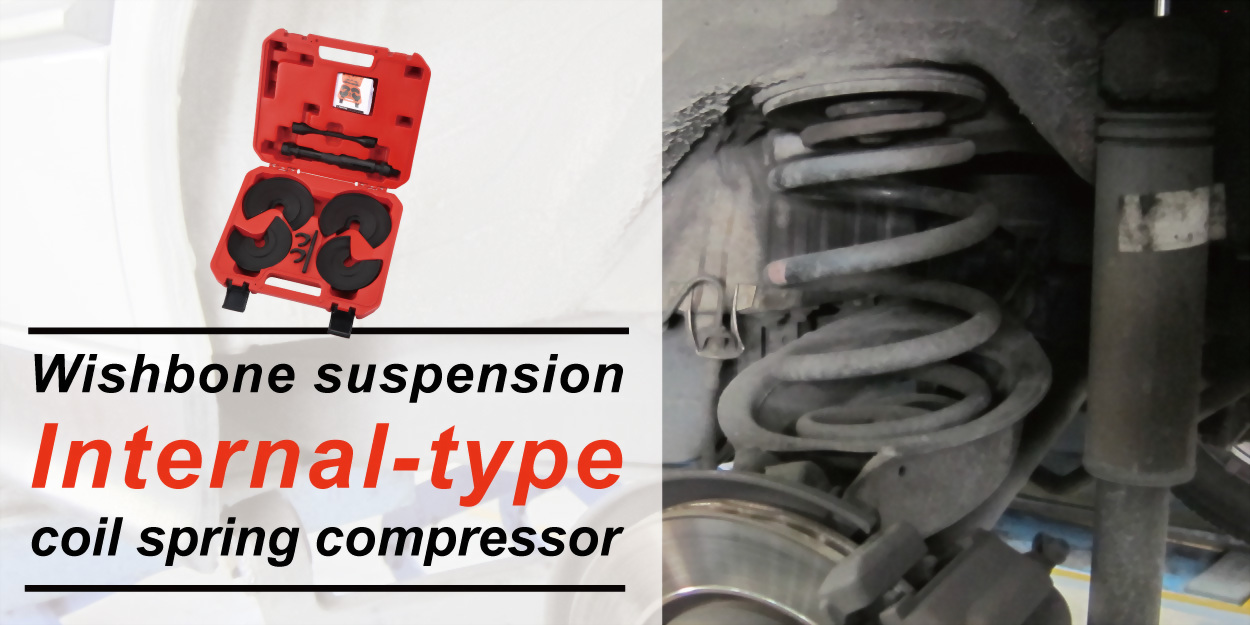

Coil Spring Compressor (Wishbone Suspension)

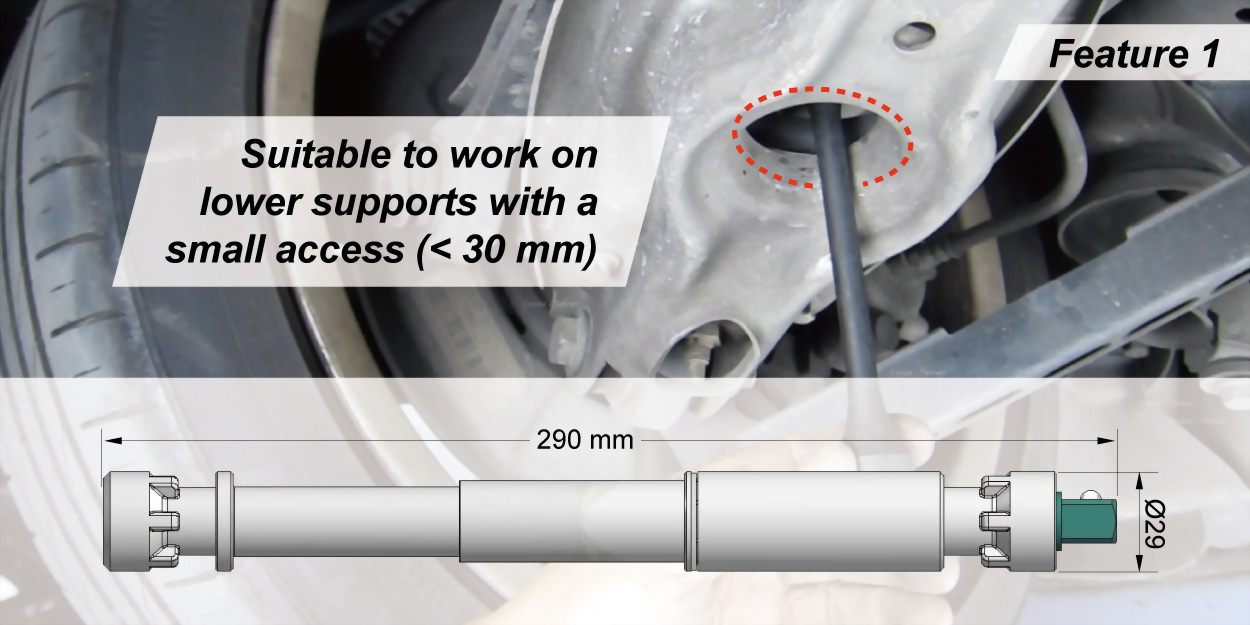

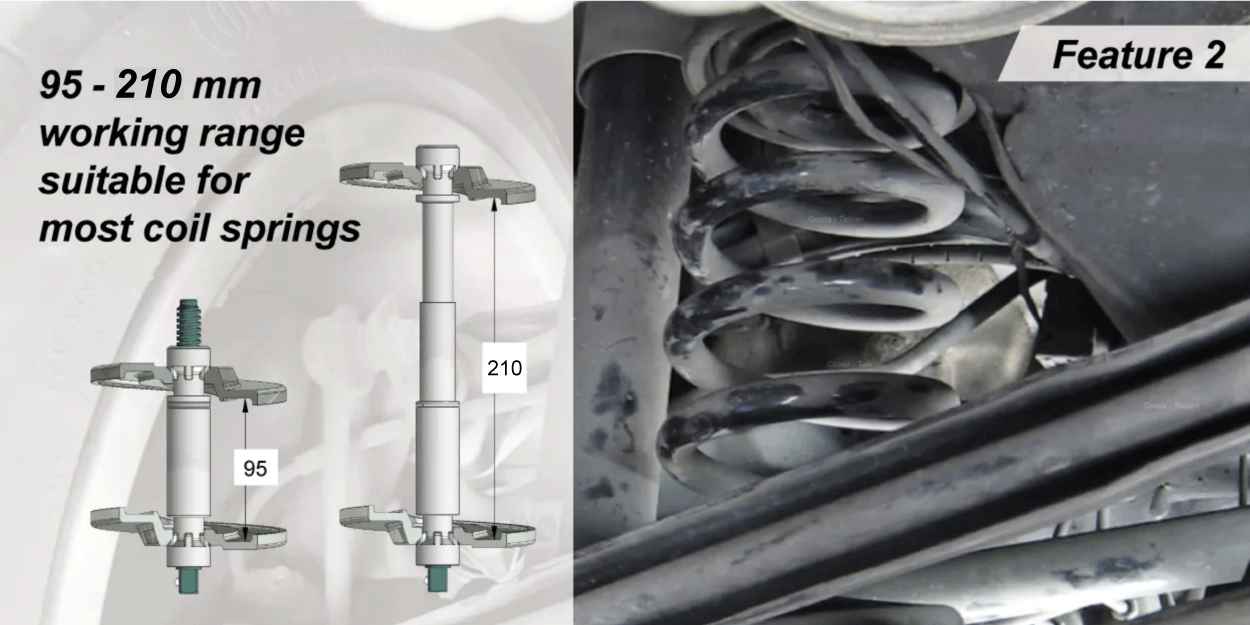

• For compressing coil springs on double A and multi-link suspensions

• Mostly on rear suspensions, sometimes on front suspensions (see Application tab below)

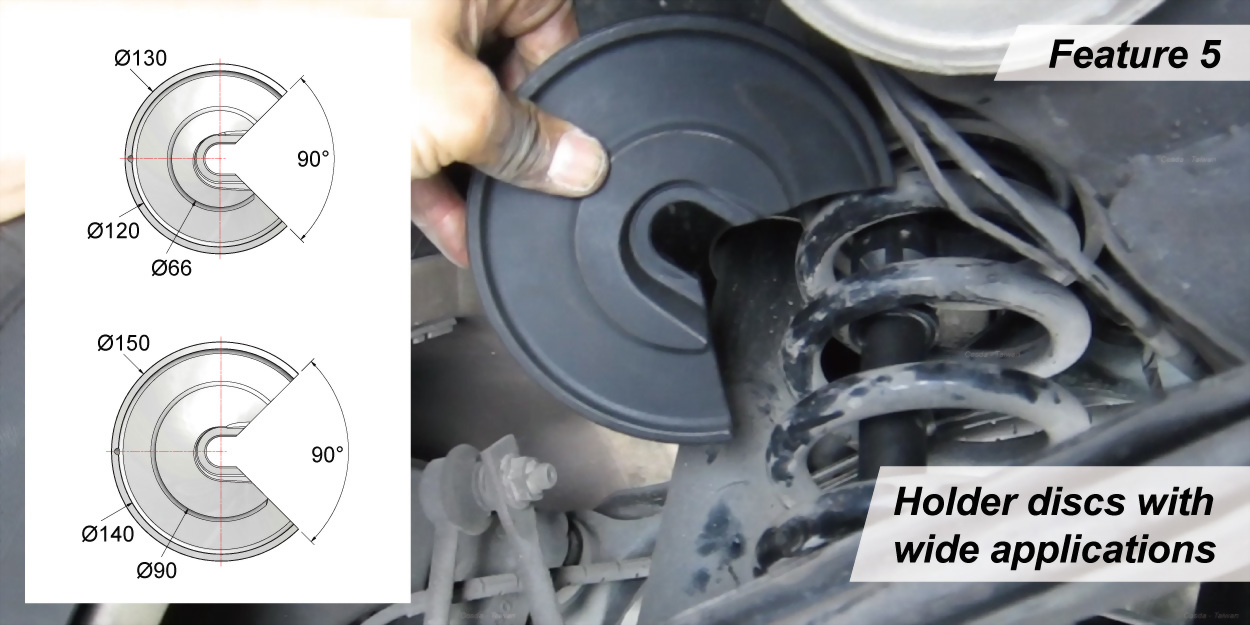

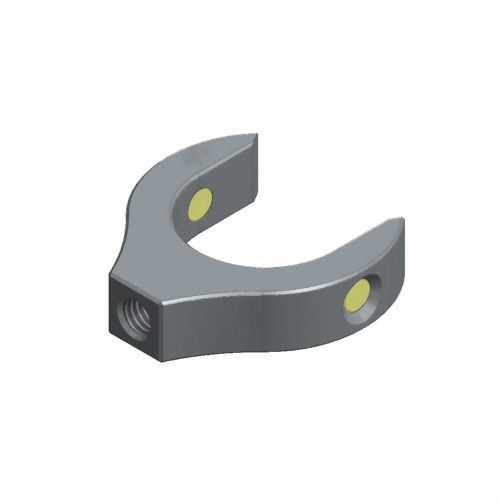

• Includes C-shaped devices for tighter connection between the discs and tool strut

• Can be operated with an air/impact wrench with the use of the 100 Nm torque bar

• Break point: 10,180 kgf (99,764 N)

• Maximum load: 4,072 kgf (39,900 N)

• Provided with Product Liability Insurance

What is a double wishbone type of shock absorber?

A double wishbone shock absorber is a component within the double wishbone suspension system, a type of independent suspension commonly used in performance-oriented and luxury vehicles. The double wishbone suspension system is known for its superior handling and ride quality, and the shock absorber plays a crucial role in this setup.

Key Features of a Double Wishbone Type Shock Absorber:

1. Separate from the Control Arms:

- In a double wishbone suspension, the shock absorber (damper) is mounted independently of the control arms (the "wishbones"). The upper and lower control arms guide the wheel's movement, while the shock absorber primarily handles damping.

2. Damping Function:

- The shock absorber in a double wishbone system is responsible for controlling the up-and-down movement of the vehicle's wheels by dampening the oscillations of the coil springs. This helps to maintain tire contact with the road and provides a smooth, controlled ride.

3. Positioning:

- The shock absorber is typically positioned vertically or at an angle, mounted between the vehicle’s chassis and the lower control arm. The precise positioning allows for optimal damping and load distribution, contributing to the system’s superior handling characteristics.

4. Independent Suspension Movement:

- The double wishbone design allows each wheel to move independently of the others. The shock absorber plays a critical role in ensuring that each wheel’s movement is well-damped, reducing body roll, pitch, and dive during acceleration, braking, and cornering.

Benefits of a Double Wishbone Type Shock Absorber:

1. Superior Handling:

- The double wishbone suspension system, aided by the shock absorber, offers precise control over wheel movement, which translates to better handling, especially in high-performance driving conditions.

2. Improved Ride Quality:

- The independent operation of the shock absorbers and control arms allows for better absorption of road imperfections, leading to a smoother ride.

3. Reduced Body Roll:

- The geometry of the double wishbone setup, combined with the shock absorber's damping capabilities, helps minimize body roll during cornering, improving vehicle stability.

4. Customization and Tuning:

- The double wishbone design allows for greater flexibility in tuning the suspension for specific driving conditions. The shock absorber's damping characteristics can be adjusted to suit different performance needs.

5. Better Camber Control:

- The double wishbone suspension system allows for better camber control (the angle of the wheels relative to the road), especially during cornering. The shock absorber works in harmony with the control arms to maintain optimal tire contact with the road.

Common Applications:

- The double wishbone suspension system, including its shock absorbers, is commonly found in high-performance sports cars, luxury vehicles, and some SUVs and trucks. It is favored in vehicles where precise handling, ride quality, and performance are prioritized.

Summary:

The double wishbone type of shock absorber is a key component in the double wishbone suspension system, which is known for its superior handling and ride quality. Positioned independently of the control arms, the shock absorber works to dampen wheel movement, providing a smooth ride, reducing body roll, and enhancing overall vehicle performance. This design is particularly favored in vehicles where precision and performance are essential.

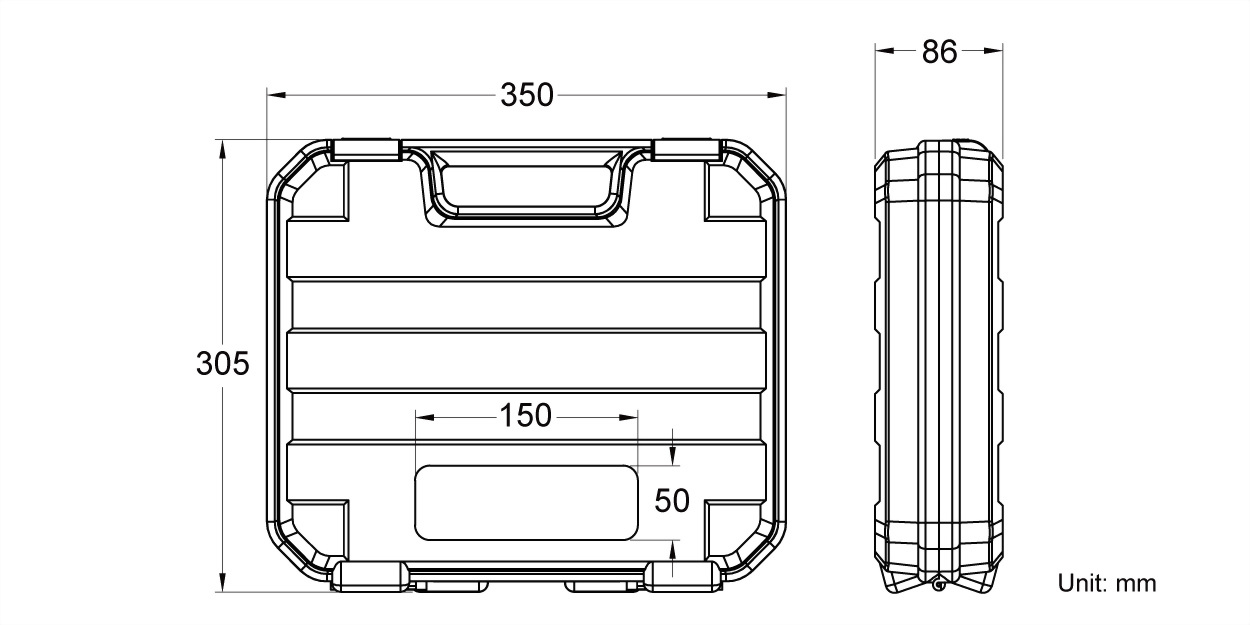

| Package | Blow molded case (red) | |

| Packing | 4 sets in a master carton | |

| Weight per set | 5.1 kg | 11.2 lbs |

| Net weight per carton | 20.4 kg | 44.9 lbs |

| Gross weight per carton | 21.4 kg | 47.0 lbs |

| Size per set | 35.0 × 30.5 × 8.6 cm | 13.8 × 12.0 × 3.4 in |

| Size per carton | 36.5 × 36.0 × 33.0 cm | 14.4 × 14.2 × 13.0 in |

| Volume per carton | 0.004 CBM | 1.6 CUFT |

| Sticker size | 14.9 × 4.9 cm | 5.8 × 1.9 in |

| No. | Image | Cosda No. | Description | |

|---|---|---|---|---|

| 1 |  |

SD-1001F-1 | Telescopic Spring Compressor Tool Body | More |

|

- Specifications

|

||||

|

|

||||

| 2 |  |

SD-1001F-07 | Small Holder Plate (Ø130 mm) | More |

|

- Specifications

|

||||

|

|

||||

| 3 |  |

SD-1001F-08 | Large Holder Plate (Ø150 mm) | More |

|

- Specifications

|

||||

|

|

||||

| 4 |  |

SD-1001F-09 | Extension Torque Bar (100 Nm) | More |

|

- Specifications

|

||||

|

|

||||

| 5 |  |

SD-1001F-10+11 | C-shaped Device | More |

|

- Specifications

|

||||

|

|

||||

| 6 |  |

SD-1001F-12 | C-shaped Device Fastening Bar | More |

|

- Specifications

|

||||

| Suggested HS Code |

82055990909 |

| MOQ with laser marking | 8 sets |

| MOQ without laser marking | 4 sets |

| Laser marking cost | + TWD 3 on body or on discs |

Certificates of Product Liability Insurance and CE certificate are shown below