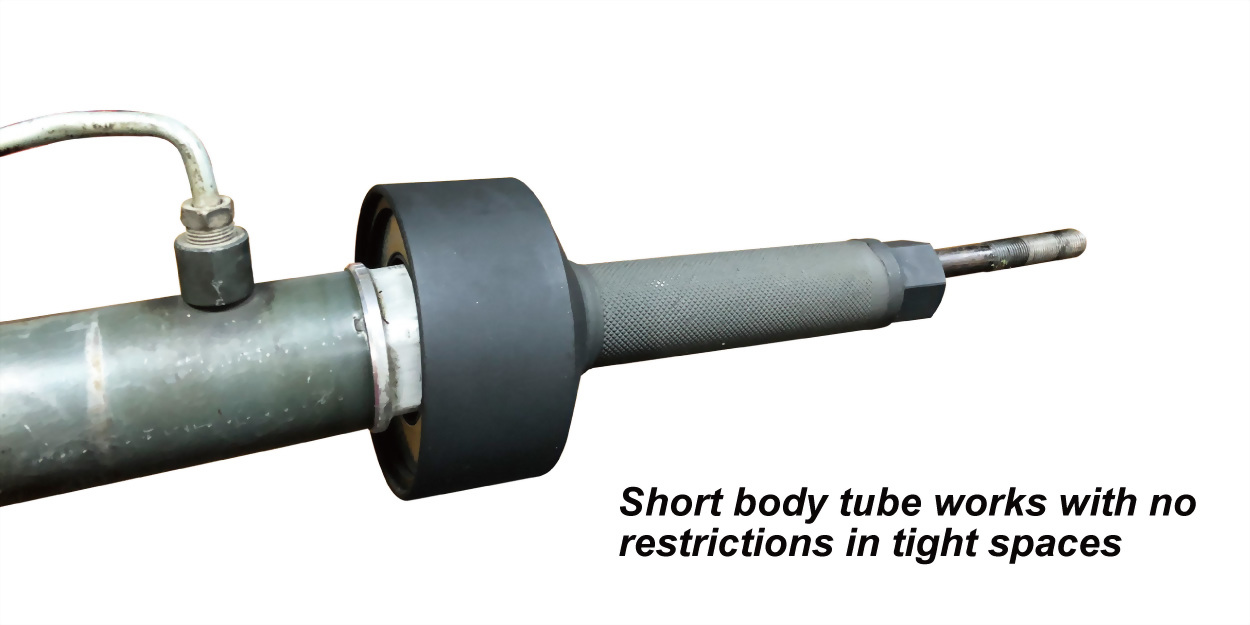

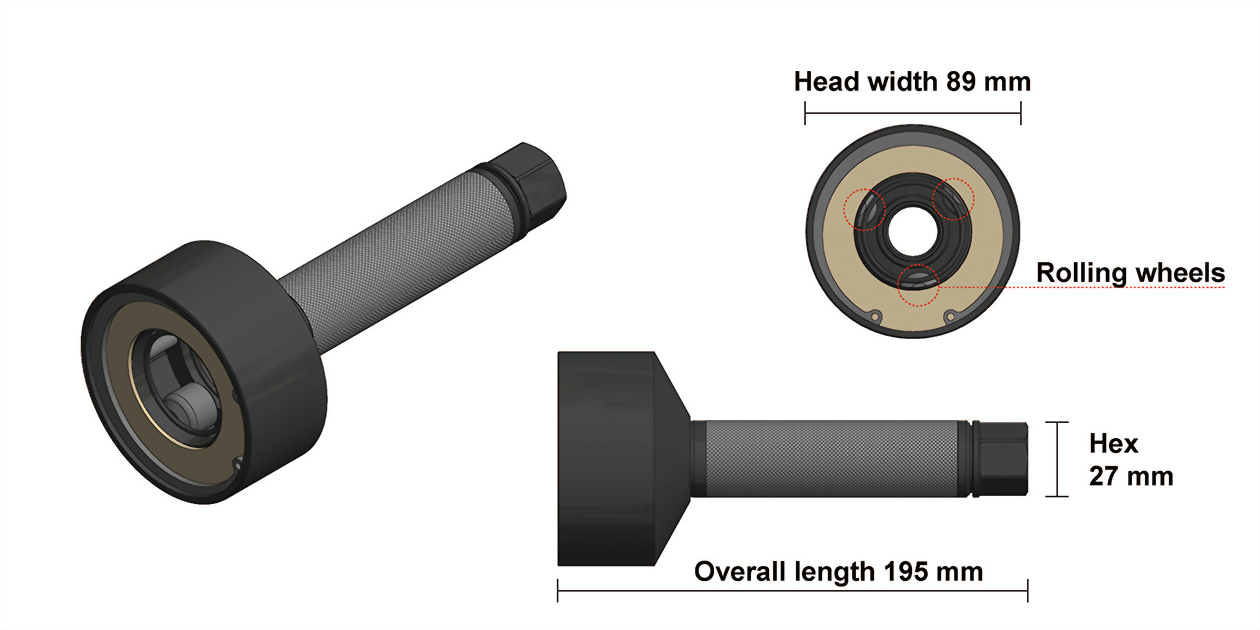

Inner Tie Rod Tool (Ø35-45mm, 195 L)

• Special head design grips tie rod end firmly by turning clockwise and anti-clockwise

• Application range Ø35-45 mm, mainly for European passenger cars

• Overall length with only 195 mm, suitable for working in limited spaces

• Tool NOT designed to be used with an air/impact wrench

What is a tie rod?

A tie rod is a crucial component of a vehicle's steering system. It serves to transmit force from the steering center link or rack gear to the steering knuckle, causing the wheels to turn. Tie rods have two main parts: the inner tie rod and the outer tie rod. These parts work together to allow for precise control of the vehicle's direction.

Here's a more detailed look at its functions:

1. Connecting Steering Components: The tie rod connects the steering rack or center link to the steering knuckle on each front wheel.

2. Transmitting Steering Force: When you turn the steering wheel, the motion is transmitted through the steering gear or rack and pinion, then through the tie rods to the wheels, causing them to turn.

3. Adjusting Alignment: The length of the tie rods can be adjusted to ensure proper wheel alignment, which is crucial for even tire wear and accurate steering.

4. Absorbing Road Shock: Tie rods also help absorb some of the shock from the road, contributing to a smoother ride.

Regular inspection and maintenance of tie rods are important for vehicle safety and performance, as worn or damaged tie rods can lead to steering issues and uneven tire wear.

Maintaining tie rods is essential for ensuring vehicle safety and performance. Here are the key maintenance steps for tie rods:

What maintenance does a tie rod require?

1. Regular Inspection: Routinely check the tie rods for signs of wear and tear, such as:

- Loose or damaged rubber boots.

- Excessive play or movement when the wheel is off the ground.

- Rust or corrosion on the tie rod ends.

2. Greasing (if applicable): Some tie rods have grease fittings (zerk fittings) and require periodic lubrication. Grease the tie rods during regular vehicle service intervals to prevent wear.

3. Check for Symptoms of Wear: Pay attention to signs indicating that the tie rods might need attention, such as:

- Uneven tire wear.

- Difficulty steering or a loose steering wheel.

- Strange noises, like clunking or knocking, especially when turning.

- Vibration in the steering wheel.

4. Wheel Alignment: Have the vehicle's alignment checked regularly, especially if new tie rods are installed. Proper alignment ensures even tire wear and optimal steering performance.

5. Replacement: Replace tie rods if they show signs of significant wear or damage. It's crucial to replace them in pairs (inner and outer) on the same side to ensure balanced performance, and this is where this special tool SD-1091E is needed for facilitating your tie rod end replacement.

6. Professional Inspection: During routine maintenance or when experiencing steering issues, have a professional mechanic inspect the tie rods as part of a comprehensive suspension and steering system check.

| Package | White box | |

| Packing | 10 set in a master carton | |

| Weight per set | 1.4 kg | 3.1 lbs |

| Net weight per carton | 14.0 kg | 30.8 lbs |

| Gross weight per carton | 15.0 kg | 33.0 lbs |

| Size per set | 10.0 × 10.0 × 20.5 cm | 3.9 × 3.9 × 8.1 in |

| Size per carton | 53.3 × 22.0 × 22.5 cm | 21.0 × 8.7 × 8.9 in |

| Volume per carton | 0.03 CBM | 0.9 CUFT |

| Suggested HS Code |

82055990909 |

| MOQ with laser marking | 20 sets |

| MOQ without laser marking | 10 sets |

| Laser marking cost | + TWD 4 on head part |