Universal Remove and Install Sleeve Kit (26 pcs)

• Equipped with sleeve sizes from 34-66mm (ID) and 44-82mm (OD) with 2mm increments

• Includes 4 spindles with two 27mm hex nuts: M10 × P1.5, M12 × P2.0, M14 × P2.0 and M16 × P2.5

• Provided with two step discs with two sides (A and B sides). Discs have tracks for fitting all sleeves, without needing several individual step discs

• Tool NOT designed to be used with an air/impact wrench

Control arm bushings on the suspensions are able to help the car drive with more stability and better comfort, but these bushings don't last forever. The most common place for a problematic bushing is the rubber ring. You can use a pry bar to move the control arms slightly on the side on the car, and check the place where the bushing is in contact with other undercar parts. The failed rubber will be easily visible with this method. Replacing a bushing can seem to be hard but with this Cosda's universal sleeve removal and installation kit, the bushing replacement job can be as easy as possible.

When working with this tool, first you want to choose the correct sized long threaded stud/rod. The size is important because it allows the threaded stud to go through the central hole of the bushing. The thickness of the 4 threaded studs provided in this kit are 10mm, 12mm, 14mm, and 16mm. The second thing is to choose the correct sized sleeves. This part takes a bit of patience. You will want to choose a receiving sleeve and a pushing sleeve. The receiving sleeve is to hold the bushing once it is pushed out of the control arm by the pushing sleeve. The receiving sleeve should fit the outside of the original bushing, and the pushing sleeve should fit the inside of the original bushing. For assembling, slide the threaded rod through the bushing hole, and connect both sleeves on either side of the bushing. Fix the sleeves with the bearing nuts provided. The sleeves come in golden and silver colors, but they are just for identification purposes. You can choose to use both golden sleeves to do the job. The sleeve sizes have 2 mm increments, and the sizes cover the majority of the bushing sizes on passenger cars.

Once the threaded rod, sleeves, and bearing nuts are fixed on the bushing, make sure that all parts are on the straight line, especially the pushing side. If the pushing sleeve goes astray, it will simply push the bushing to the edge of the control arm, and totally ruins it. Take two manual wrenches. This is important. Please do not use an air or impact wrench to work with this tool. The turning of the bearing nut will create heat. While working manually, the heat can dissipate evenly, but if you are using an air wrench, the heat created by the high speed is very likely to shear the threads clean off, so use a regular manual wrench or a ratchet wrench.

Finally, fix one bearing nut and tighten the other bearing nut. By fastening, the pushing sleeve will gradually push the original bearing out of the control arm. For installing a new bearing, use the same method to push the new bearing into the control arm. There is a concave working as a window so you can always check where the bushing goes through that window in order not to over pushing, or you will have to do the entire job again.

This high quality tool set is designed and manufactured by Cosda Manufacturing Company, a Taiwan's leading tool manufacturer focusing on B2B and ODM businesses. Cosda has been working with the world's renowned tool brands for decades, and the customers always return with happiness because of the high quality, and thus, low customer complaint and low return rate. Please feel free to contact us for more information.

| Package | Blow molded case (red) | |

| Packing | 1 set in a master carton | |

| Weight per set | 18.0 kg | 39.6 lbs |

| Net weight per carton | 18.0 kg | 39.6 lbs |

| Gross weight per carton | 19.0 kg | 41.8 lbs |

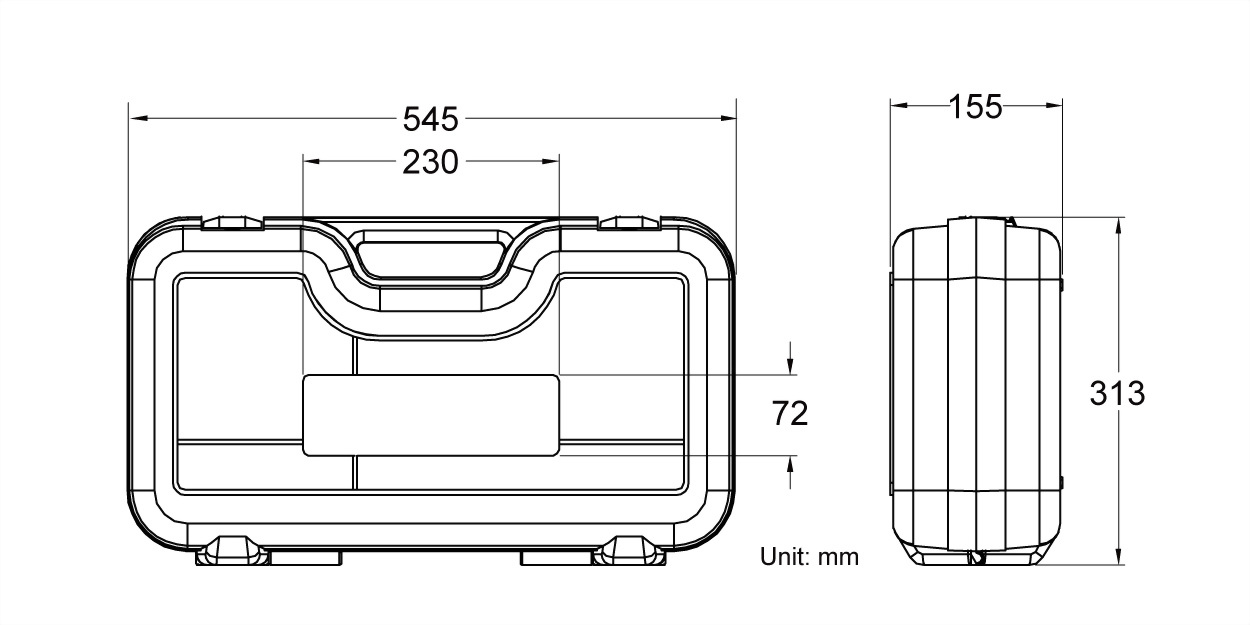

| Size per set | 54.5 × 31.3 × 15.5 cm | 21.3 × 11.8 × 5.5 in |

| Size per carton | 55.7 × 32.4 × 17.0 cm | 21.9 × 12.8 × 6.7 in |

| Volume per carton | 0.03 CBM | 1.1 CUFT |

| Label size on case | 22.9 × 7.0 cm | 9.0 × 2.8 in |

| No. | Image | Cosda No. | Description | |||||

|---|---|---|---|---|---|---|---|---|

| 1 |  |

SD-1107-01 | Step Disc | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 2 |  |

SD-1107-2 | M10 Spindle with two M10 nuts | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 3 |  |

SD-1107-3 | M12 Spindle with two M12 nuts | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 4 |  |

SD-1107-4 | M14 Spindle with two M14 nuts | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 5 |  |

SD-1107-5 | M16 Spindle with two M16 nuts | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 6 |  |

SD-1107-34 | Sleeve Ø44 × Ø34 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 7 |  |

SD-1107-36 | Sleeve Ø46 × Ø36 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 8 |  |

SD-1107-38 | Sleeve Ø48 × Ø38 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 9 |  |

SD-1107-40 | Sleeve Ø50 × Ø40 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 10 |  |

SD-1107-42 | Sleeve Ø52 × Ø42 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 11 |  |

SD-1107-44 | Sleeve Ø54 × Ø44 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 12 |  |

SD-1107-46 | Sleeve Ø56 × Ø46 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 13 |  |

SD-1107-48 | Sleeve Ø58 × Ø48 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 14 |  |

SD-1107-50 | Sleeve Ø60 × Ø50 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 15 |  |

SD-1107-52 | Sleeve Ø62 × Ø52 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 16 |  |

SD-1107-54 | Sleeve Ø64 × Ø54 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 17 |  |

SD-1107-56 | Sleeve Ø66 × Ø56 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 18 |  |

SD-1107-58 | Sleeve Ø68 × Ø58 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 19 |  |

SD-1107-60 | Sleeve Ø70 × Ø60 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 20 |  |

SD-1107-62 | Sleeve Ø72 × Ø62 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 21 |  |

SD-1107-64 | Sleeve Ø74 × Ø64 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 22 |  |

SD-1107-66 | Sleeve Ø76 × Ø66 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 23 |  |

SD-1107-68 | Sleeve Ø78 × Ø68 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 24 |  |

SD-1107-70 | Sleeve Ø80 × Ø70 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 25 |  |

SD-1107-72 | Sleeve Ø82 × Ø72 | More |

||||

|

- Specifications

|

||||||||

| Suggested HS Code |

82055990909 |

| MOQ with laser marking | 20 sets |

| MOQ without laser marking | 1 set |

| Laser marking cost | + TWD 3 each marking |

| Change BMC color to black | MOQ 300 sets |

| Change BMC color to other colors | MOQ 500 sets |

Набор универсальных втулок для замены сайлентблоков, Set di 27 attrezzi Estrattore di boccole del trapezio Cuscinetto dell'assale, Juegos de hierro Extractor de manga de goma, Coffret extracteur Silent Bloc bagues outils pour montage et demontage de Roulements