Hydraulic Flaring Tool Set

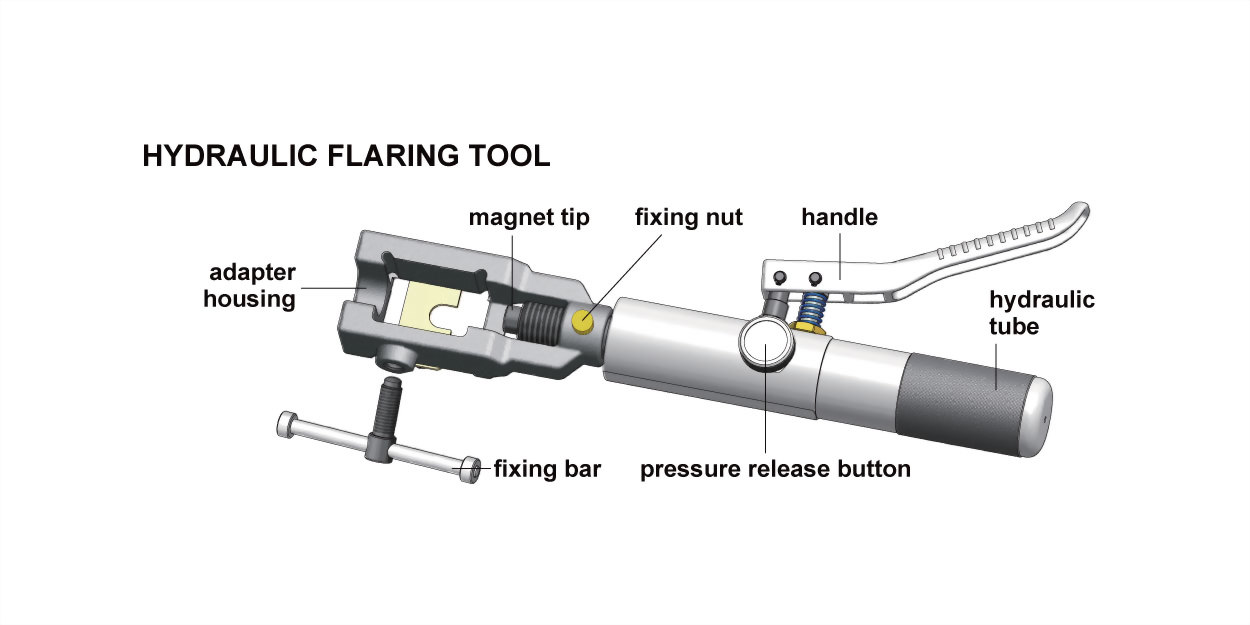

• Magnet inside the flare housing helps position the die and adapters in place

• Flaring tool utilizes hydraulic force to help reduce resistance and increase work efficiency

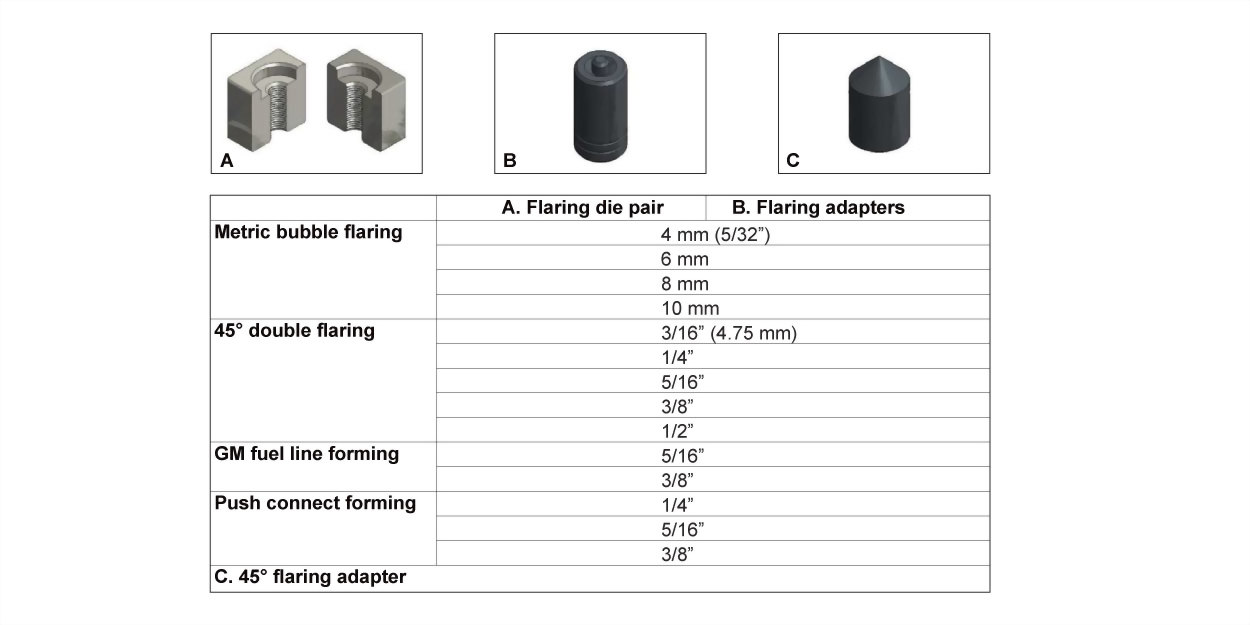

• Includes several adapters and dies for metric bubble flaring, 45° double flare, GM fuel line, and push connect

Flaring tubing is done whenever a tube needs to connect to a flare-type fitting and must seal fluid under pressure. In automotive systems, this is most commonly seen in brake, transmission, and fuel lines. Here are the occasions you must flare the tube:

When the system uses flare fittings

The tube must be flared to match the fitting if the factory or replacement line uses:

-

Double flares (SAE/45° inverted flares) — common in brake systems

-

ISO bubble flares — common on many European/Asian brake systems

When making or repairing brake lines

Brake systems operate at very high pressure (often 1,000–2,000+ psi).

A flare is required whenever you:

-

Cut a brake line to repair a rusted or damaged section

-

Fabricate a custom brake line

-

Install an aftermarket brake kit requiring new hard lines

Brake lines almost always require double flares (SAE) or bubble flares (ISO) depending on the vehicle.

When fabricating metal fuel lines

If you are:

-

Replacing a damaged hard fuel line

-

Upgrading to AN fuel systems

-

Running high-pressure fuel injection lines (steel or NiCopp)

You flare the tube to properly seal on the fitting.

Carbureted low-pressure systems may also use simple flare connections, often 45° double flare, depending on the hardware.

When installing or modifying transmission cooler lines

Transmission fluid lines use:

-

45° double flares, or

-

37° AN flares for aftermarket setups

Whenever you cut or make your own hard transmission lines, you flare the tube.

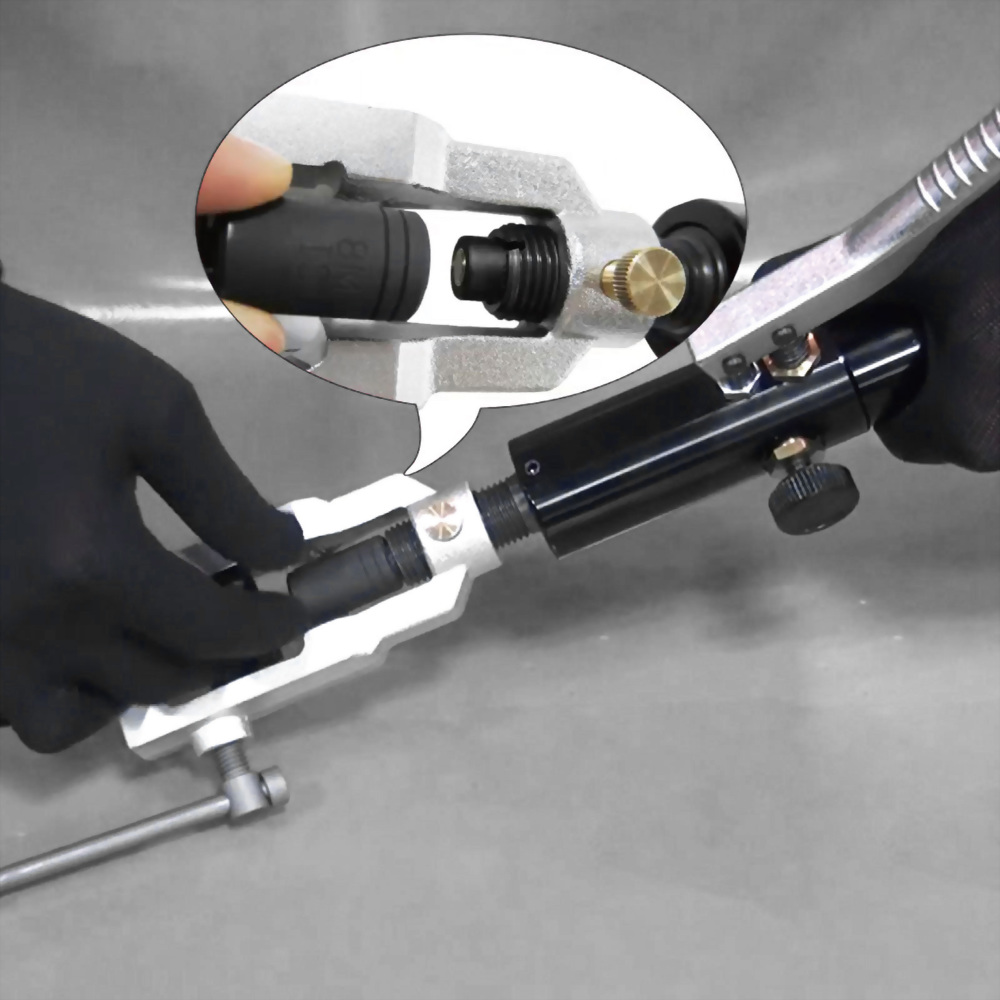

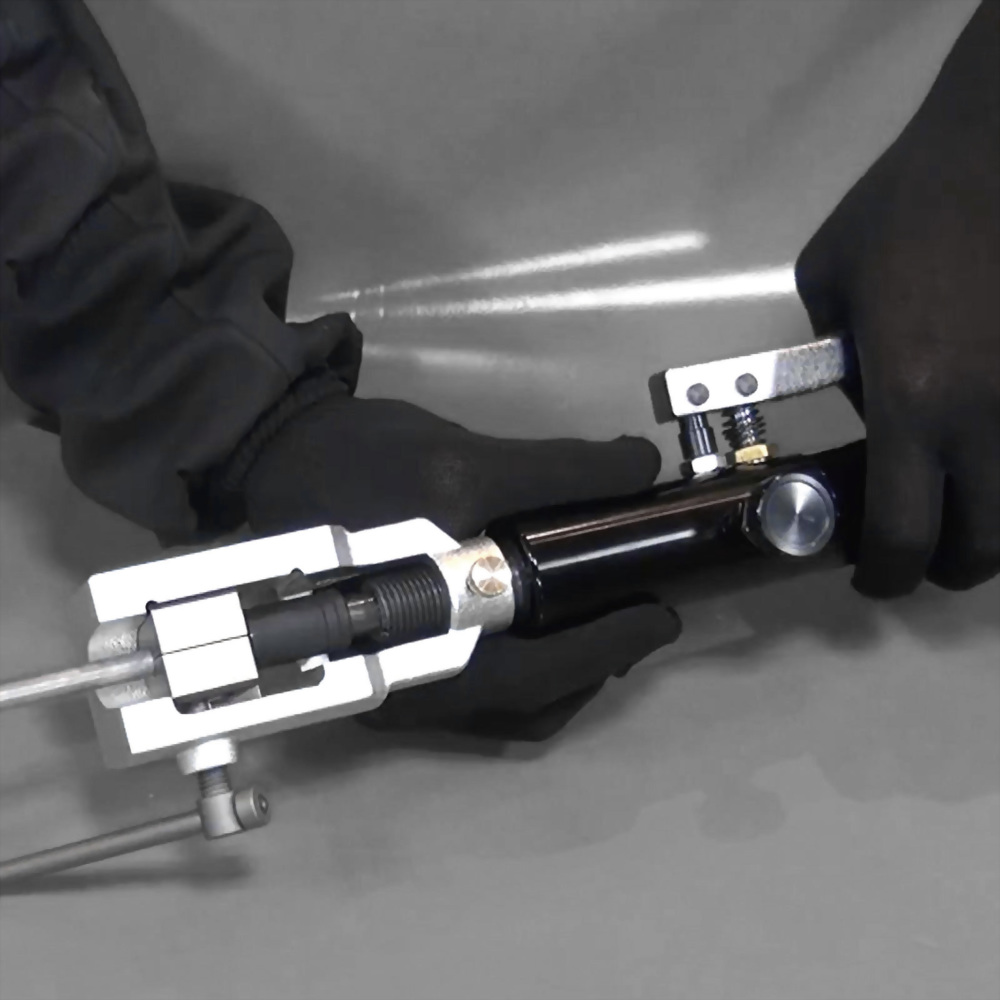

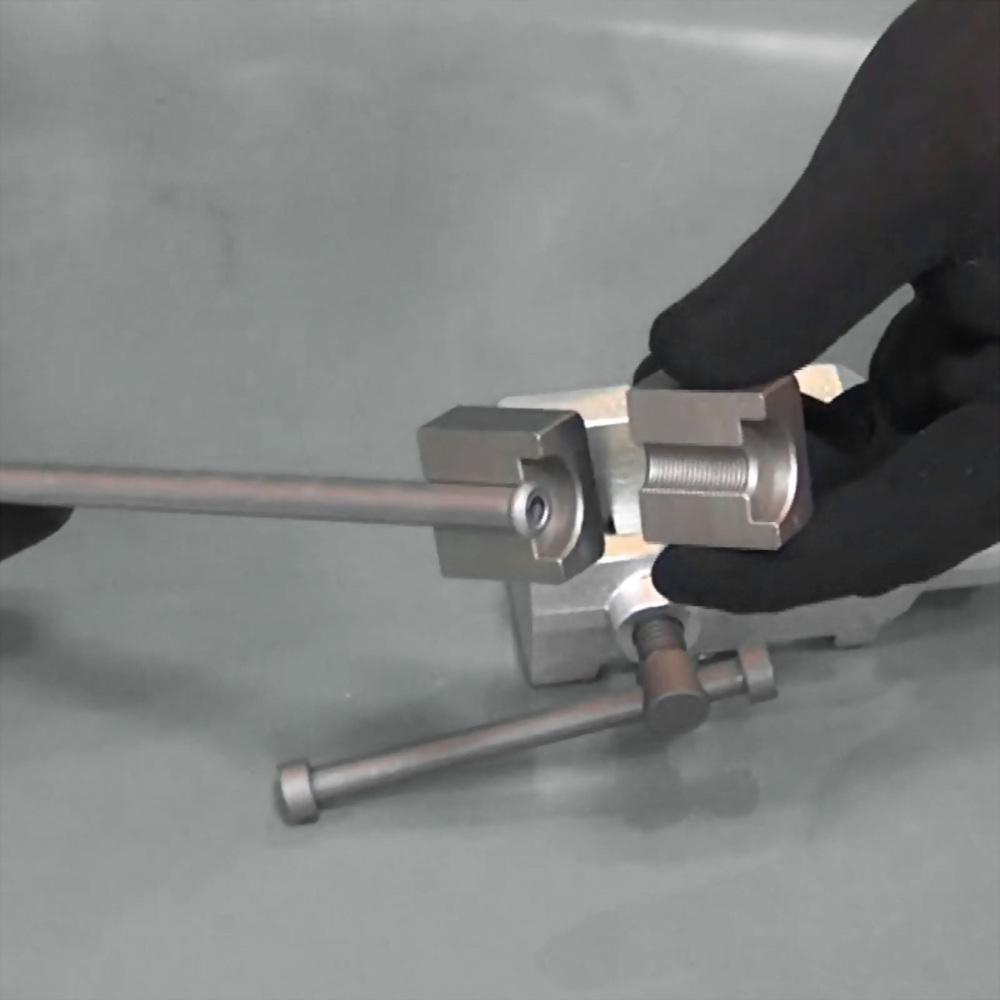

Flaring tubes may seem to be intimidating but with the help of Cosda hydraulic flaring tool, things get easy and fast. Just simply find the right adapter and the dies, and insert the tube to be flared inside the dies, and the dies to be placed in the adapter housing. Fix the dies inside the housing with the fixing bar on the side. The corresponding adapter should be placed on the magnetic tip, and the magnet helps keep the adapter constantly in place during the flaring process.

Once the tube, adapter, and the dies are correctly situated, fix everything all together with the golden rotor. Release the rotor on the handle, and start to press the handle several times. The hydraulic force helps the process very well. It creates a large force without you noticing it and the flaring process can be done in a short period of time.

Please feel free to contact Cosda directly if you would like to have more information on this product, and we will reply to your inquiry in a timely manner.

Package: Red blow molded case

Packing: 2 sets in a master carton

Weight per set: 5.3 kg

Net weight per carton: 10.6 kg

Gross weight per carton: 11.6 kg

Size per set: 42 × 28 × 8.8 cm

Size per carton: 43 ×30 × 19.4 cm

Case label size: 12.5 × 5 cm

Volume per carton: 0.9 CUFT

Suggested HS code: 82042000

MOQ with logo laser marking: 20 sets

MOQ without logo laser marking: 2 sets

Logo laser marking cost: + TWD 2 each marking

Not for sale in: China