Fluid Drum with a Pour Spout (5 Liter / 5 US Quart)

coolant. ✓ engine oil, gear oil, coolant, brake fluid, ATF; ✗ gasoline, diesel, solvents

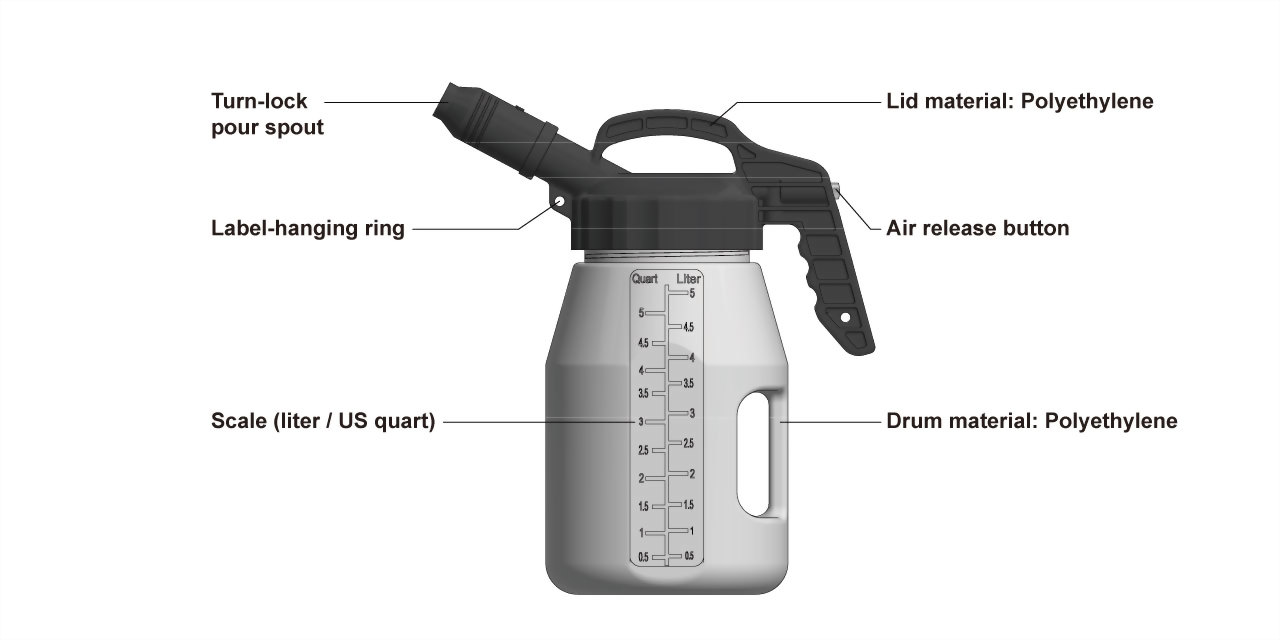

• Lid with a pour spout with a turn lock and a air release button for easy pouring and dust-free storage.

• Capacity: 5 liter or 5 US quart

• Handles on lid and drum are for easy transporting and pouring

• Provided with a label for identification purposes

KEY FEATURES

1. Purpose-Built for Automotive

and Equipment Maintenance

Clearly marked “Not for use with gasoline, diesel or solvents” to reduce misuse and comply with professional maintenance procedures.

2. Translucent Drum – Instant

Check of Level and Fluid Condition

The

translucent wall lets you see the remaining volume and color changes at a

glance, making accurate dispensing and inventory control easier.

Ideal

for workshops, fleets and DIY users for repeated, long-term use.

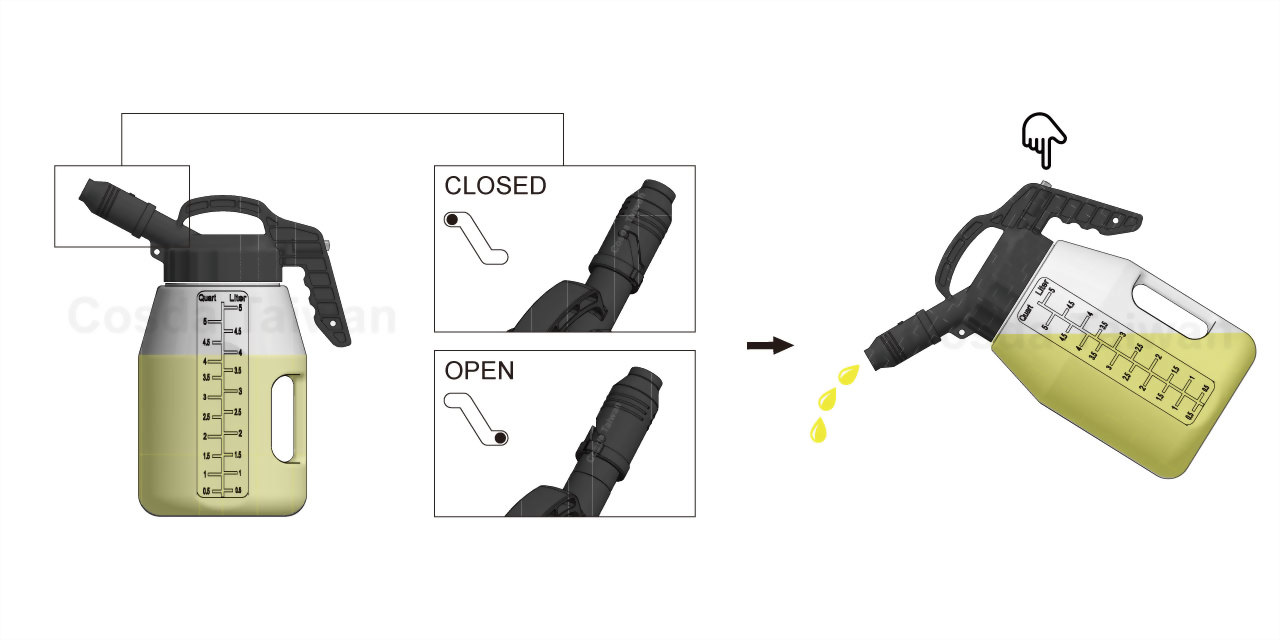

3. Professional Pouring System: Locking Spout + Air-Release Button

The

lid integrates a lockable pour spout and air-release button:

-

Twist-to-lock design helps prevent leakage and keeps dust out during storage and transport

-

Air-release button stabilizes flow, reducing splashing and “glugging” while pouring.

Especially suitable for professional environments that require precise filling into small openings such as engine oil fillers or transmission inlets.

4. Dual-Handle Ergonomic Design

– Easy Handling Even When Full

Both

the drum body and lid are equipped with handles for easier carrying, tilting

and angle control.

Even

when filled with 5 L of fluid, it can still be held securely, reducing the risk

of slipping or spills and improving safety in everyday use.

5. Writable Label Area for

Organized, Traceable Fluid Management

A

dedicated writable label area allows you to mark fluid type,

brand/specification, opening date and application (such as vehicle license

plate or machine ID).

This

supports complete maintenance records and meets the management requirements of

professional fleets and workshops.

6. Wide Application Range – For

Professionals and Advanced DIY Users

Highly

suitable for automotive and motorcycle service shops, industrial and agricultural

equipment maintenance units, fleet operations, and serious DIY enthusiasts.

It

combines professional design, clear safety indication and practical convenience

in one reliable container for storing, decanting and pouring a wide variety of

fluids.

TECHNICAL SPECS TABLE

Capacity

Material

Operating temp

Spout OD

Drum OD×H

Weight (set)

5 L/5 US qt

HDPE

0~45 °C

Ø29.2mm

Ø190 x 300mm

1.4 kg/3 lb

WHY FLUID NEEDS TO BE STORED SAFETY?

U.S.

Fire Administration:

Basements

and garages present additional fire safety risks compared to other home areas.

Flammable liquids, storage of combustibles, gas appliances and electrical tools

can lead to fires.

Garage fires tend to spread farther and cause more injuries and dollar loss

than fires that start in all other areas of the home.

Biohazard

First and foremost, an indoor

oil spill can be a biohazard. Oil is a toxic substance that can cause harm to

both people and the environment. When oil spills and leaks occur indoors, the

fumes and vapors can quickly spread throughout the space, contaminating the air

and potentially causing respiratory problems. Inhalation of heating oil fumes

can cause headaches, nausea, and dizziness. Additionally, coming into contact

with oil can cause skin irritation.

Fire-Risk

Another concern with indoor

oil spills and leaks is the potential for fire. Oil is highly flammable; even a

single spark can ignite it, leading to a dangerous and potentially deadly fire.

And this is especially true if the oil is near a heat source, such as a furnace

or water heater.

Structural Damage

In addition to the immediate dangers posed by indoor oil spills and leaks, there are also long-term risks. Oil can seep into the flooring and walls, causing damage to the structure of the home, which can lead to costly repairs and renovations down the line.

1. Why should fluids be stored separately?

When different fluids mix, they may trigger chemical reactions, degrade in quality, or lose their intended lubrication and cooling properties. Storing fluids separately preserves their performance and allows technicians to quickly identify the correct type during service, reducing operational errors. In professional workshops, using smaller transfer containers also improves handling efficiency and avoids the inconvenience of dealing directly with large, heavy drums.

2. Why is a dedicated fluid storage container necessary?

Automotive fluids are highly sensitive materials, and their quality directly affects the safety and performance of engines, transmissions, and brake systems.

A proper storage container provides:

- Dust protection: prevents dirt and metal particles from entering and causing wear.

- Moisture protection: reduces water contamination, preventing emulsification or performance loss.

- Contamination control: minimizes the risk of foreign particles entering critical fluids such as engine oil or brake fluid

3. Why can’t it store gasoline, diesel, or solvents?

The key issue lies in the chemical compatibility of

the NBR gasket.

The container body is made of HDPE

(High-Density Polyethylene), which offers excellent resistance to most

automotive fluids.

However, the NBR (Nitrile Rubber) gasket in the cap

is not compatible with substances such as gear oil, gasoline, diesel, and

solvents.

Long-term exposure may cause the gasket to swell, harden, or crack.

Once the gasket deteriorates, sealing performance decreases, leading to:

- Leakage

- Vapor escape

- Increased fire hazards

4. Why are

transparent or semi-transparent containers needed in workshops?

Transparent or

semi-transparent materials allow technicians to visually check fluid levels at

a glance, reducing the risk of mistakes.

A visible fluid level offers:

-

Immediate confirmation of remaining volume

-

Reduced chances of pouring or filling the wrong fluid

- Lower risk of cross-contamination

In fast-paced workshop environments, the ability to quickly assess fluid status significantly improves safety and overall work efficiency.

5. Common risks in workshop

fluid storage

Incorrect storage of

automotive fluids can create both immediate and long-term hazards for personnel

and the environment, including:

- Fire risk from leaks: spilled or leaking fluids can ignite when exposed to heat sources or electrical equipment.

- Degradation from exposure: contact with air accelerates oxidation and reduces the fluid's effectiveness.

- Contamination in open containers: dust and metal shavings can easily enter, leading to fluid contamination that may damage components.

Proper storage minimizes operational errors, protects equipment, and ensures compliance with workshop safety standards.

SOLUTION

Solution 1 – Brand Identity & Custom-Printed Fluid Drums

Turn SD-1280 into a fully branded oil container and custom printed oil jug, creating a professional look and consistent brand identity for your workshop and distribution channels.Key Benefits:

- Your logo and product information can be printed directly on the main flat area of the drum body, transforming it into a premium 5 liter oil container with logo that stands out in any workshop.

- The MOQ for logo-printed drums is 120 sets, making it a practical private label fluid drum option for lubricant brands and distributors.

- Custom outer cartons and combo packaging allow you to build a complete OEM lubricant packaging solution, for example a drum plus extension tube kit for service packages.

- By combining direct printing with labels, a single custom printed oil jug can serve multiple markets or campaigns simply by updating the sticker content.

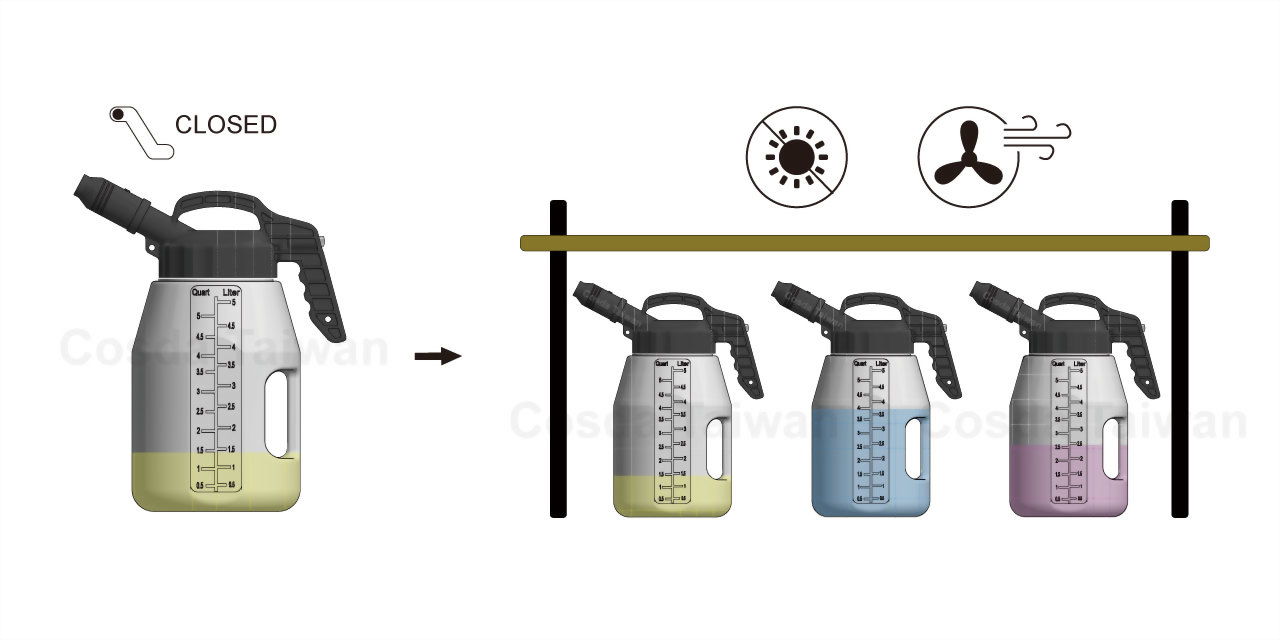

Solution 2 – Color-Coded Spouts for Easy Fluid Identification

Use color-coded spouts to build a clear fluid identification system that helps avoid oil misfilling and supports a safer, more organized workshop safety solution.

Key Benefits:

- Spouts can be customized in different colors to create a true color coded spout and color coded oil container system; just provide your Pantone or color code and we will confirm the MOQ.

- Different fluids can be assigned different colors, forming an intuitive fluid identification system for technicians working under time pressure.

- This color-based approach helps avoid oil misfilling in busy environments and fits perfectly into visual SOPs and lean workshop layouts.It is a powerful long-term workshop safety solution for large garages, factory maintenance teams and chain networks looking to reduce mistakes and warranty claims.

Solution 3 – Precision Filling with Extension Tube Set

With the extension tube set, SD-1280 becomes a professional no funnel oil filling tool and a practical hard to reach filler neck solution for modern, compact engine bays.

Key Benefits:

- When combined with the Extension Tube Set for Fluid Drums (SD-1281A), SD-1280 works as an extension tube for fluid drum that can reach awkward filler necks easily.

- The reinforced flexible hose provides precision fluid dispensing for engine oil, coolant, gear oil and more, even when space is extremely limited.

- This setup creates a clean, controlled no funnel oil filling process – technicians no longer need to balance funnels and bottles, reducing spills and cleanup work.

- It is the ideal choice for workshops that need a reliable hard to reach filler neck solution as part of their professional oil change tools.

Solution 4 – Multi-Language Labels & Custom Stickers

Combine multi language label options and custom oil container sticker designs to build a flexible global lubricant packaging and OEM multi market solution around a single drum model.

Key Benefits:

- Custom stickers can include your logo, product name, viscosity, safety warnings, barcodes and batch areas, providing a versatile custom oil container sticker setup for different customers and regions.

- Multi-language layouts support EU and global markets, helping you meet EU compliant packaging requirements with localized multi language label content.

- The same private label fluid drum can be used worldwide by simply switching label languages and regulatory icons, keeping tooling and product structures simple.

- This strategy creates a scalable global lubricant packaging platform that makes it easier to enter new markets while controlling inventory and compliance costs.

Solution 5 – Integrated Fluid Management System (Drum + Tools)

Make SD-1280 the heart of a complete workshop fluid management system and complete fluid handling kit to support a long-term garage equipment upgrade strategy.

Key Benefits

- SD-1280 can be combined with extension tubes, extractors and refill tools to form a full workshop fluid management system from storage, to transfer, to precise dispensing.

- This integrated approach allows workshops and mobile service vans to manage multiple fluids efficiently as a unified 5 liter fluid drum solution.

- By adding brand printing, color-coded spouts and multi-language labels, every drum becomes part of a standardized garage equipment upgrade across branches and countries.

- Instead of selling just a container, you offer a complete complete fluid handling kit that increases average order value and strengthens long-term customer relationships.

Q&A

Q1.What types of fluids is this product suitable for? Can it be used with gasoline, diesel or solvents?

A: This product is suitable for engine oil, gear oil, coolant, brake fluid and ATF, as commonly used in vehicle maintenance. It is not recommended for use with gasoline, diesel or any type of organic solvent, in order to prevent material degradation or potential safety hazards.

Q2.The marking shows 5 Liter / 5 US Quart. What is the recommended working capacity?

A: This product is designed as a 5-liter (5 US quart) class container and is suitable for holding and dispensing fluids in this capacity range, with additional headspace reserved for safer and more stable operation. For precise volume measurement, the use of a measuring cup or other measuring device is recommended.

Q3.Is the container prone to leakage during transport? Is it suitable for use inside a vehicle?

A: The container features a lockable lid and integrated handles on both the lid and the drum. When properly tightened and used under normal handling conditions, leakage is unlikely, making it suitable for routine movement within workshops or vehicles. However, long-term storage in a horizontal or inverted position, or use in environments with severe vibration, is not recommended.

Q4. Is this product suitable for long-term storage of fluids?

A: This product is primarily designed for short- to medium-term storage and transportation of fluids such as engine oil, gear oil and coolant. Due to the high hygroscopic nature of brake fluid, it is not recommended as a long-term storage container for brake fluid, and is better suited for filling operations or short-term transfer.

Q5.What should be noted for cleaning and maintenance? Can solvents be used for cleaning?

A: It is recommended not to use strong organic solvents or thinners for cleaning, as they may adversely affect the service life of the material. For cleaning, first fully drain any residual fluid, then rinse with a small amount of the same type of fluid or a neutral cleaning agent suitable for plastic materials, and allow the container to air-dry in a cool, shaded area before reuse.

Package: Carton box

Packing: 1 set in an inner carton, 4 sets in a master carton

Weight per set: 1.4 kg

Net weight per carton: 5.5 kg

Gross weight per carton: 6.5 kg

Size per set: 42.1 x 33.3 x 20.3 cm

Size per carton: 69.4 x 44.5 x 43.9 cm

Volume per carton: 4.8 CUFT

Suggested HS code: 39269099

MOQ with logo printing: 150 sets

MOQ without logo printing: 10 sets

Logo printing cost: + TWD 10 per unit with TWD 2,500 tooling cost

Not for sale in: China