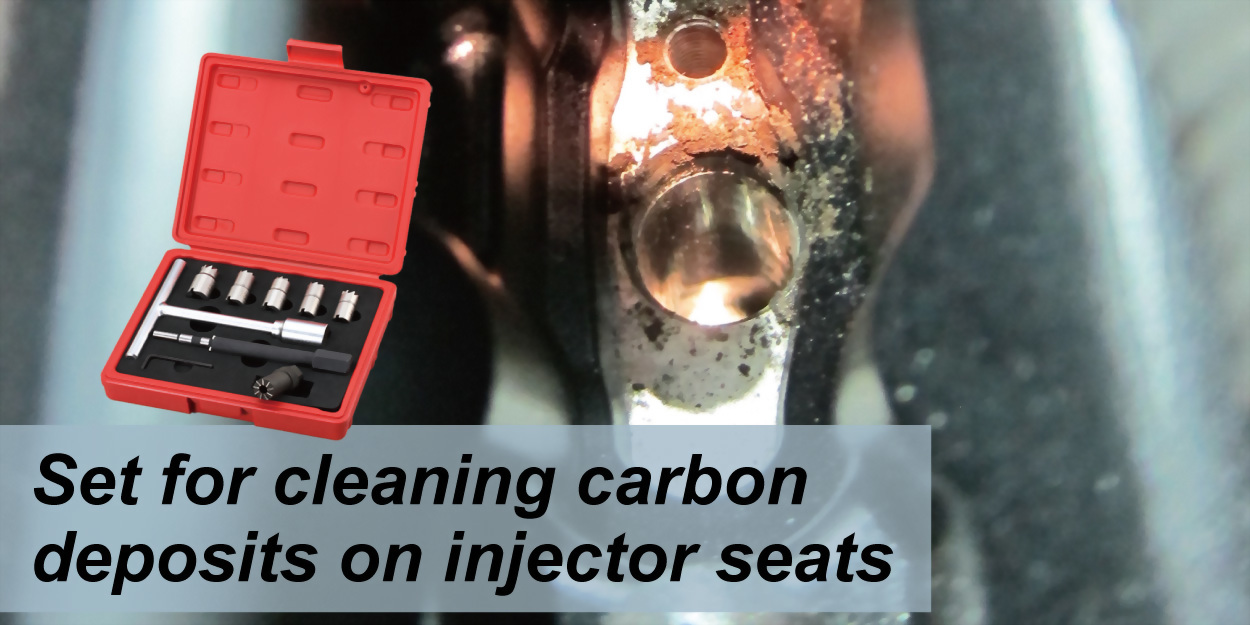

Diesel Injector Seat Cutter Set (9 pcs)

• Unique double lock design provides safer works and better results

• Contents include - 17 × 17mm flat reamer, 15 × 19mm flat reamer, 17 × 19mm flat reamer, 17 × 21mm flat reamer, 17 × 17mm angled reamer, and an injector cleaner

• Includes a pilot post and T-handle

• Helps avoid potential risks of blow-by gases

One of the most common problems for a diesel engine running inefficiently is as a result of the carbon buildup at the bottom of the injector seats. Because the diesel injectors supply misty diesel fuel directly into the combustion chambers, the unburnt carbon molecules from the diesel fuel may be blown back to the injector hole and sit around the injector at the bottom. Whenever you remove the injectors, you will need to redo your injector seats before you put the injectors back in. If you ignore this step, and just put the injectors back in regardless of the carbon buildup at the injector seat bottoms, the pressure and fuel mixture can actually escape from the gap between the injector and its seat and create a mess in the rocker arm cover.

There are several steps to remove the carbon in the injector seats. To begin with, you can use a hoover or a vacuum cleaner attached to a small tube to suck out as much as you can. This sounds fairly easy but the carbon may be quite sticky so using the vacuum air to remove the carbon may not be feasible at some point. Second step, you can start to use a tool set like this to reseat your diesel injectors.

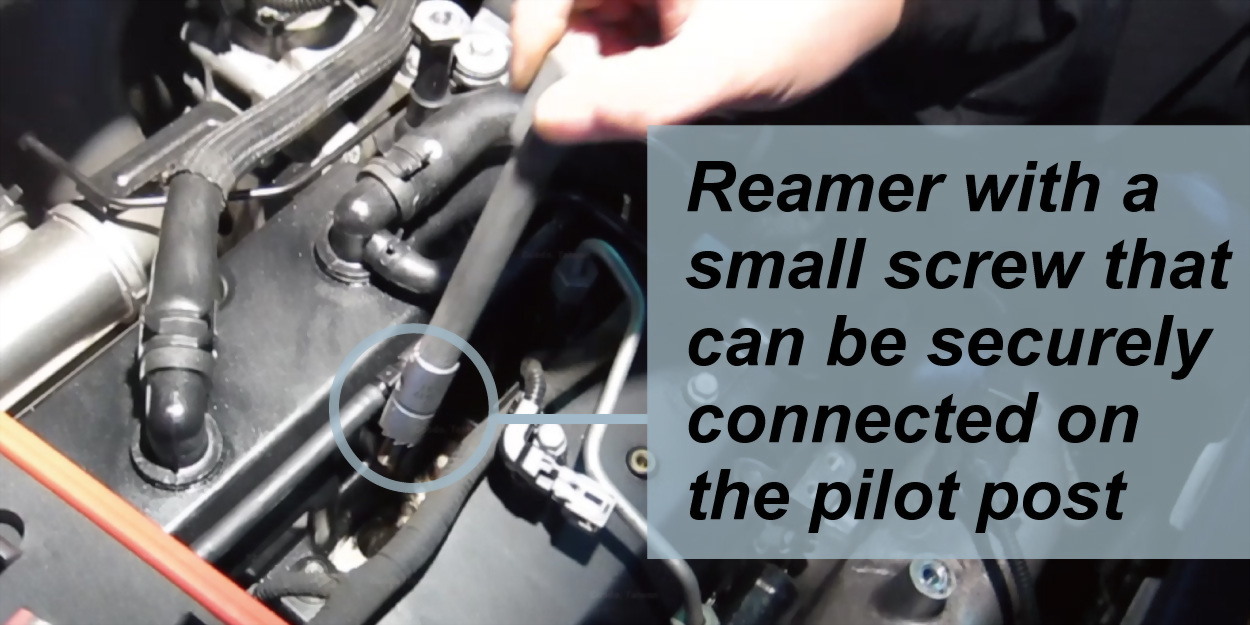

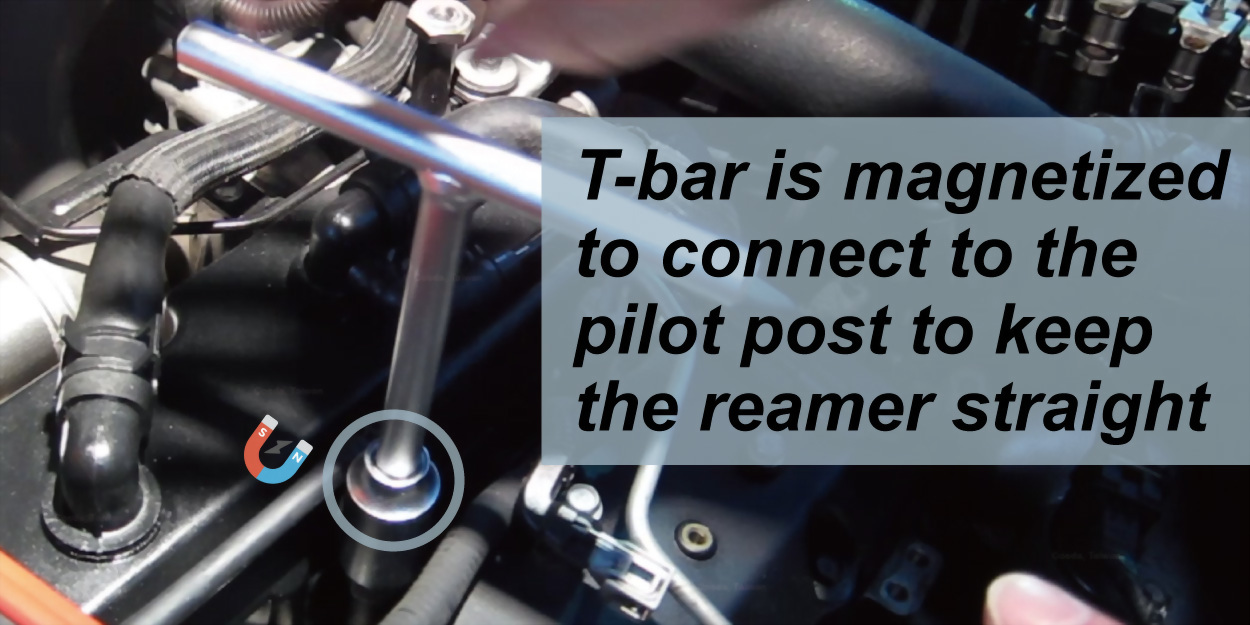

The tool set has 4 parts. The upper parts are called reamers or injector seat cutters. They have sharp edges on the tip, and they have different shapes, sizes, and angles. Find a suitable one that sits perfectly for the injector well. Attach the reamer onto the pilot post and use the Allen key provided to secure both parts together. Connect the external hex on the other end of the pilot post to the internal hex part of the T handle. There’s a magnet inside so the T handle can be securely attached to the pilot post when you are turning.

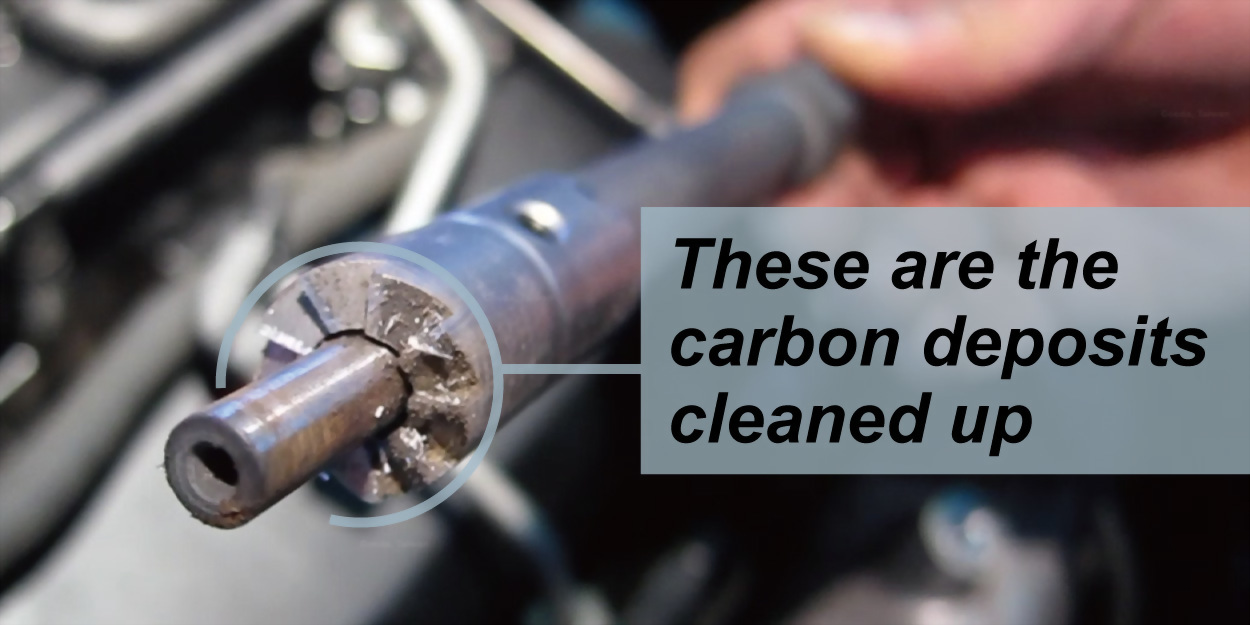

Once the tool is well assembled, apply some grease at the tip of the reamer. The grease is able to catch the carbon scraped off and stay on the reamer because you don’t want any carbon remnant falling into the combustion chamber. Insert the tool into the injector well and turn the T handle while applying a bit of pressure at the same time. You can feel the amount of carbon by the friction when you are turning. When there’s a high friction, it may indicate that there is a lot of carbon for that injector seat. Use the vacuum cleaner to pick up any carbon residue after using the seat cutter, and finally check the quality of the cleaning result. You may continue to clean other cylinders if you have taken out their injectors too. After all the injector wells are cleaned, fit new copper washers to the injectors and you can fit the injectors back in.

This tool set is designed and manufactured by Cosda Manufacturing Company, a well known specialty tool company in Taiwan. Cosda has several other related products for diesel engine services, and we provide private label, OEM / ODM services to our customers. If you are looking for a tool manufacturer just like us, please feel free to contact us directly.

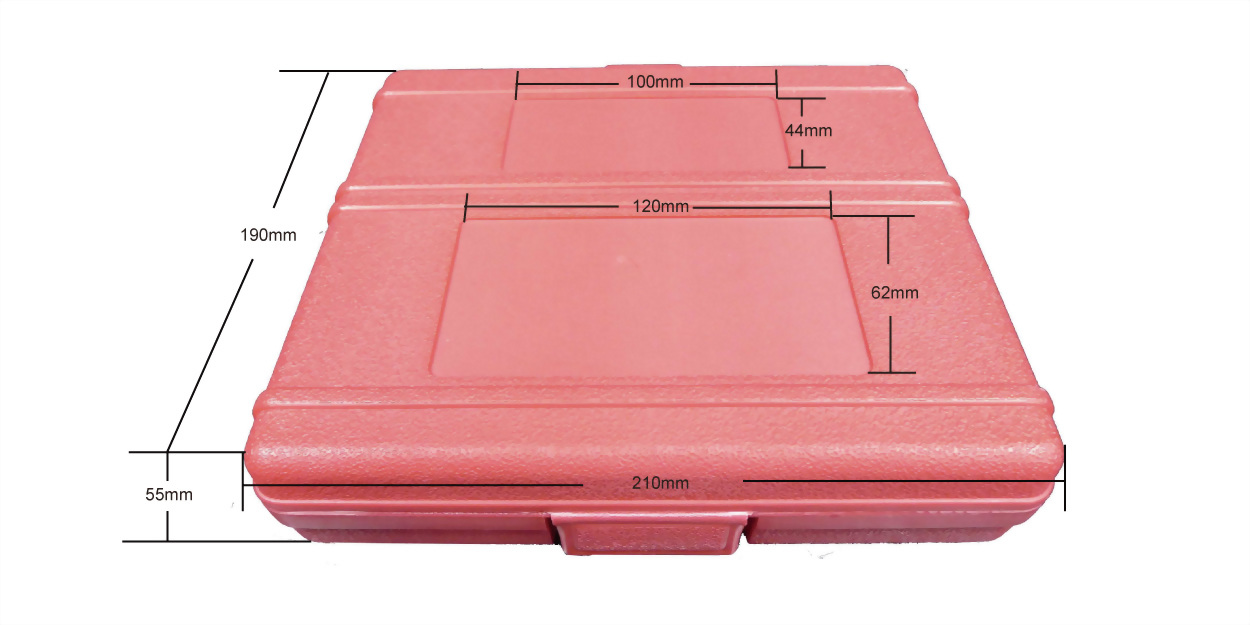

| Package | Blow molded case (red) | |

| Packing | 10 sets in a master carton | |

| Weight per set | 1.2 kg | 2.6 lbs |

| Net weight per carton | 11.7 kg | 25.7 lbs |

| Gross weight per carton | 12.7 kg | 27.9 lbs |

| Size per set | 21.0 × 19.0 × 5.5 cm | 8.3 × 7.5 × 2.2 inch |

| Size per carton | 40.0 × 27.9 × 22.4 cm | 15.7 × 11.0 × 8.8 inch |

| Volume per carton | 0.025 CBM | 0.9 CUFT |

| Case label size | 9.5 × 4.0 cm, 11.5 × 5.7 cm | 3.7 × 1.5 inch, 4.5 × 2.2 inch |

| No. | Image | Cosda No. | Description | |||||

|---|---|---|---|---|---|---|---|---|

| 1 |  |

JT-605 | T Bar | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 2 |  |

SD-1081_BODY | Pilot Post | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 3 |  |

SD-1081-02 | Allen Wrench 2.5mm | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 4 |  |

SD-1081-3A | 17 × 17 mm Flat Reamer | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 5 |  |

SD-1081-4A | 15 × 19 mm Flat Reamer | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 6 |  |

SD-1081-5A | 17 × 19 mm Flat Reamer | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 7 |  |

SD-1081-6A | 17 × 21 mm Angled Reamer | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 8 |  |

SD-1081-7A | 17 × 17 mm Angled Reamer | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 9 |  |

SD-1081-09 | Injector Cleaner | More |

||||

|

- Specifications

|

||||||||

| Suggested HS code |

82059000008 |

| MOQ with laser marking | 20 sets |

| MOQ without laser marking | 10 sets |

| Laser marking cost | + TWD 4 on T handel, + TWD 2 on each reamer |

Diesel-Einspritzdüsen-Sitzreiniger, Diesel verstuiver zitting reiniger, Frézy na úpravu sedel diesel vstřikovačů, очиститель сидений дизельного инжектора, SADA FRÉZ NA SEDLÁ VSTREKOVAČOV