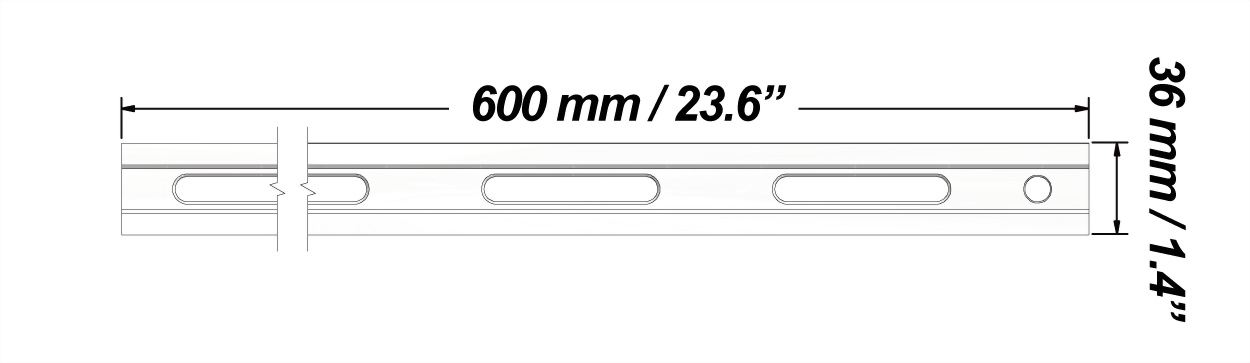

Cylinder Head Surface Rectifier (600mm)

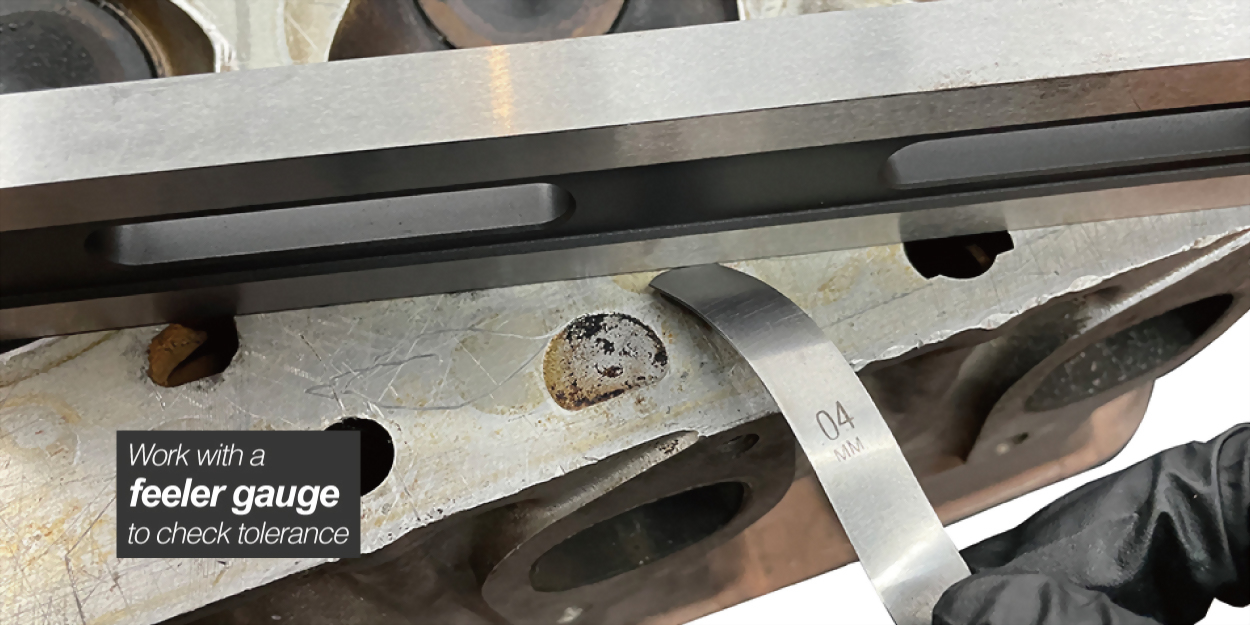

• Work with a feeler gauge

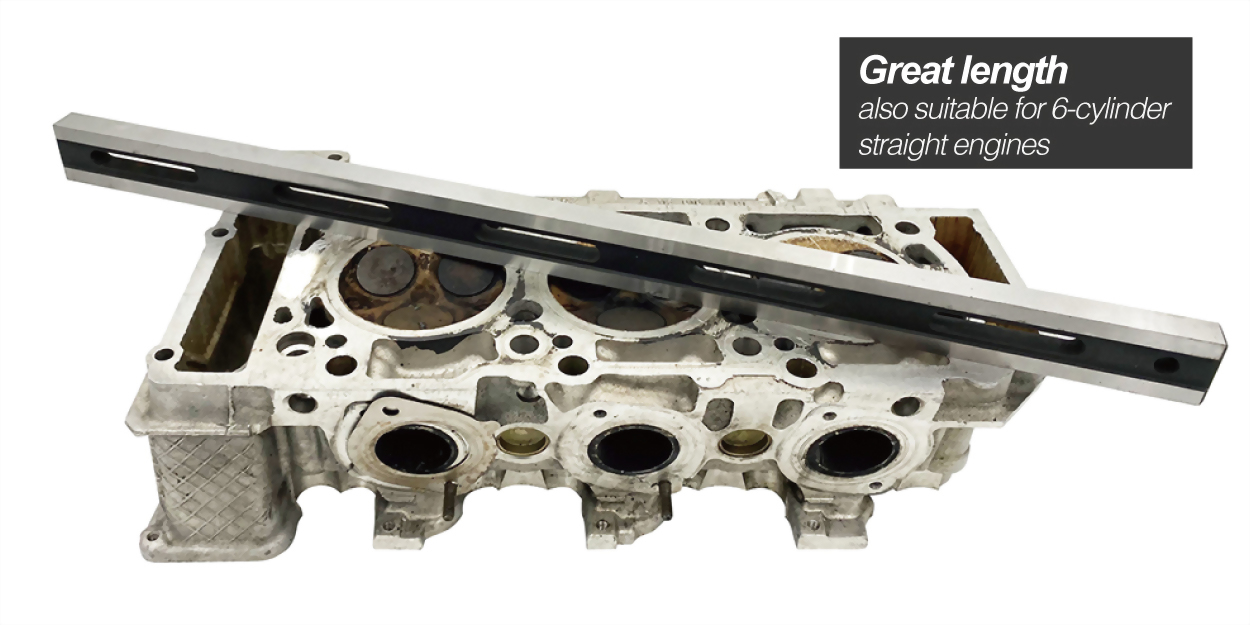

• Suitable for 4- and 6-cylinder engines

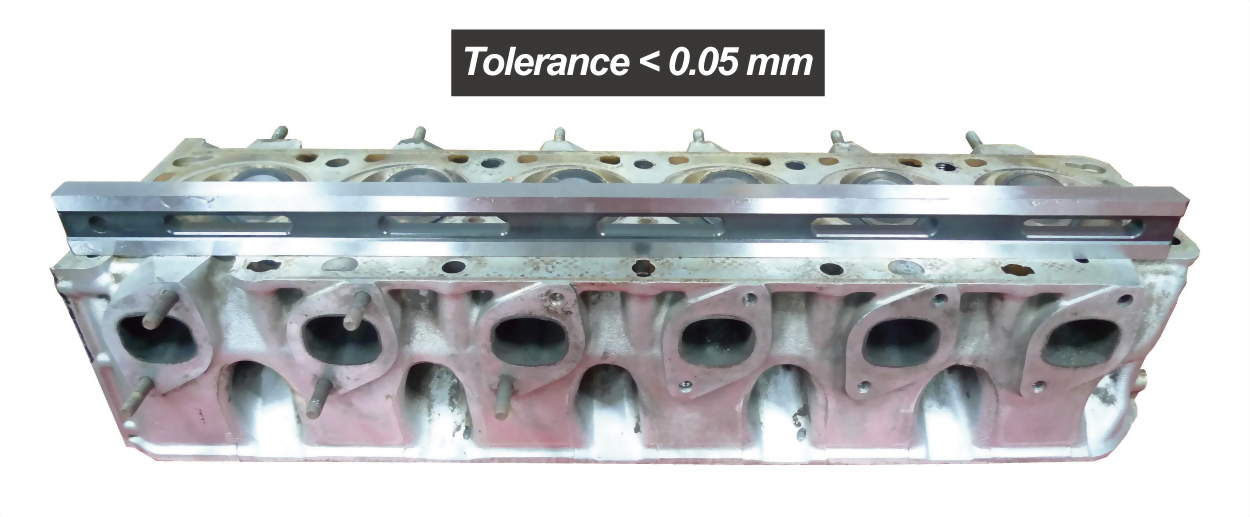

• Tolerance < 0.05 mm

Frequently Asked Questions

Q1. What is the primary purpose for the Cylinder Head Surface Rectifier (600 mm) SD-1010?

A1. This tool is designed to check the flatness of cylinder heads and engine blocks when we are rebuilding engines or simply resurfacing the cylinder head. Its 600 mm length allows measurement on 3-, 4-, and 6-cylinder engines.

Q2. What is the flatness tolerance of this straight edge?

A2. The tolerance is smaller than 0.05 mm, ensuring the precision for the flatness check work on engines.

Q3. Which engines or vehicles can it be used on?

A3. The 600 mm size is ideal for most passenger-car and light-truck engines, including 4- and 6-cylinder inline engines, but for larger engines, longer straight edges are recommended. If longer straight edge tools are hard to find, use this tool and check the big engines in several sections.

Q4. How do I use the surface rectifier with a feeler gauge?

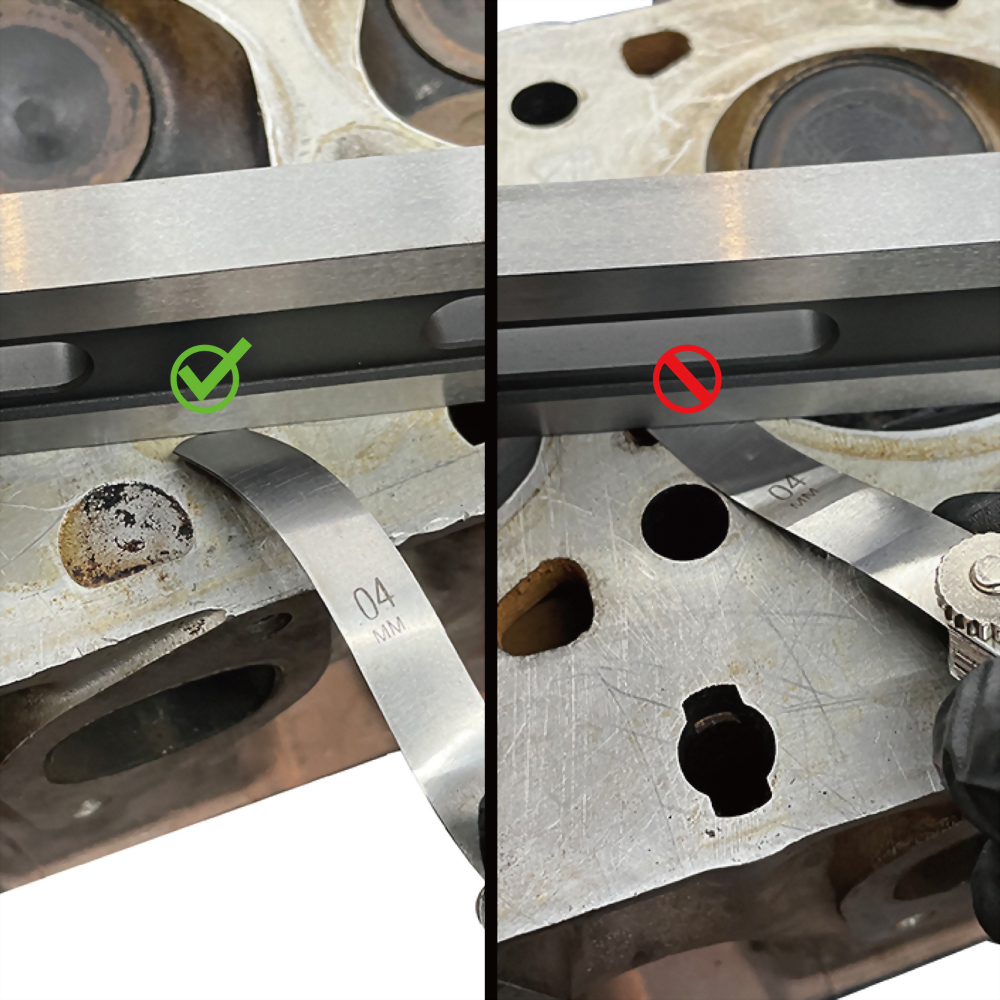

A4. Place the rectifier along the cylinder head sealing surface and insert a feeler gauge at multiple points. Mark all the places that has gaps larger than the feeler gauge, which means the feeler gauge goes through under the rectifier tool, and those places require resurfacing.

Q5. What material is the SD-1010 made from?

A5. It is constructed from hardened, precision-ground steel to maintain straightness and resist wear over repeated use.

Q6. How should I maintain and store the tool?

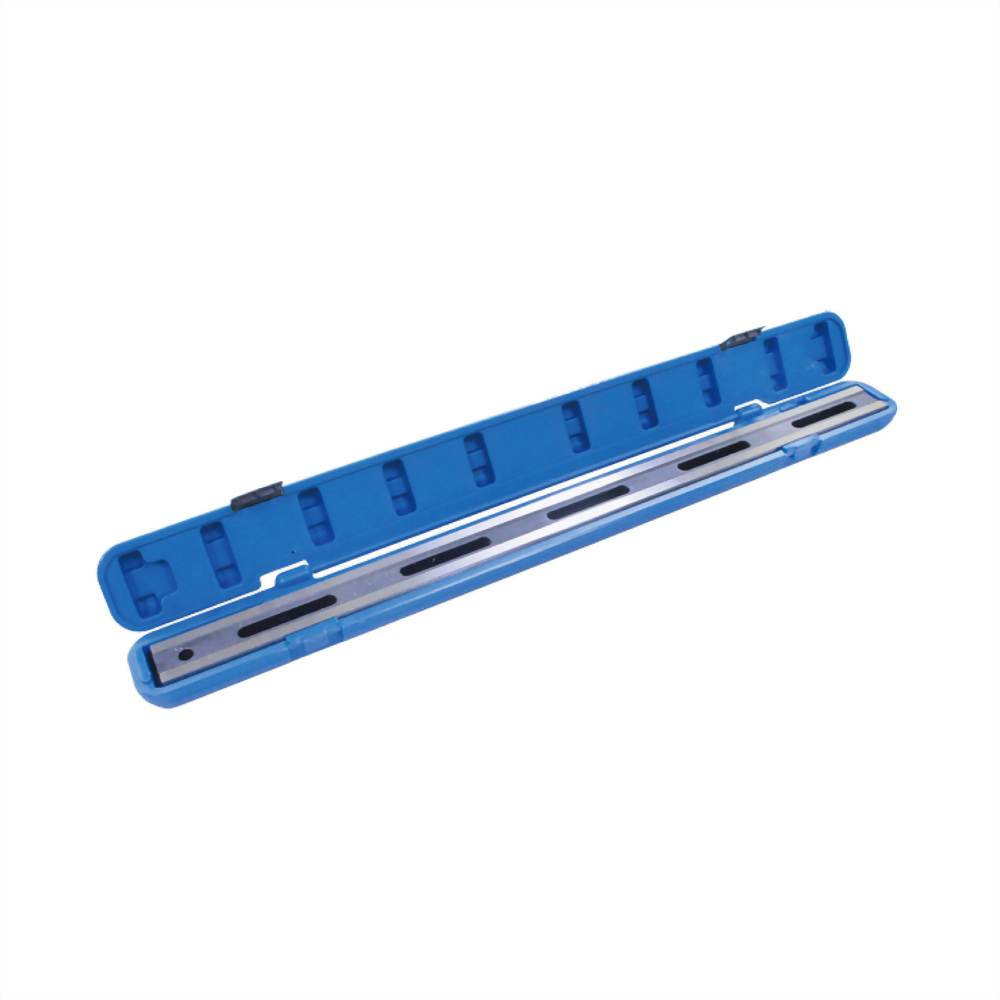

A6. After each use, wipe the surface clean, lightly oil the tool to prevent oxidation, and store it in the supplied protective case to avoid bending or accidental damage. In fact, when you receive the tool after purchase, the tool should be wrapped in a plastic bag with oil protection on it. Keep it that way to avoid rusts.

Checking the straightness on the cylinder head is tricky. Internal combustion engines might be one of the most impressive works of mankind, but at the same time, the engines have a highly sophisticated and complex structure. A small fault in the engine may strongly affect the engine’s feasibility and efficiency. For example, tiny leaks in the cooling system may cause the system not able to retain its pressure, and coolant may be leaking and that leads to a reduced amount of coolant, and eventually cause the engine to overheat. Overheating is also a very common cause of cylinder head warping that can make the engine components to be bent, twisted, or out of shape in general, including a blown head gasket.

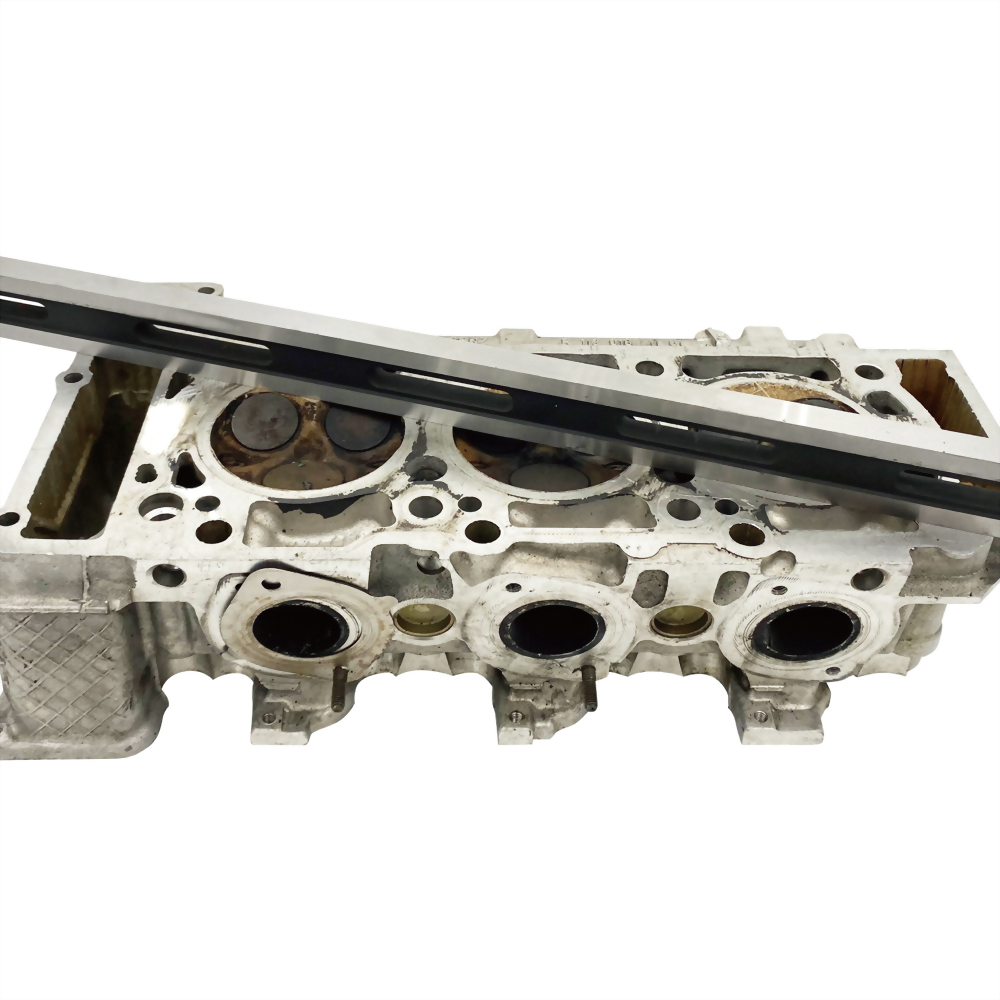

When a bulged or warped cylinder head occurs, you might want to sand, mill, or if you have professional machines to resurface the cylinder head deck to be as flat as possible. After the cylinder head deck is resurfaced, use this straight edge tool to check the straightness, or flatness, of the cylinder head.

To check the straightness is very simple. You will need a feeler gauge or feeler blade. Refer to the automotive manufacturer’s service manual for the standard tolerance, for example, one and half thousandth of an inch, or two thousandth of a millimeter.

Place the straight edge tool on the cylinder head deck, you will need to check five different places, that is, three places lengthwise across the deck (two sides and the middle), and two places when you put the straight edge diagonally. Use the feeler gauge or blade to check if the gauge can run through the straight edge. If it can, it means that that area is not as flat as you want them to be.

Alternatively, you may also use a flashlight if you don’t have a feeler gauge available. Just simply check if you can see the light shine through. If the light goes through, the warpage still exists. The flashlight method may be even more accurate because light can run through much smaller gaps than the feeler gauge does.

This tool is designed and manufactured by Cosda Manufacturing Company, an automotive specialty tool manufacturer located in Taiwan, and is one of the most renowned special tool manufacturers in the world. We have been working with famous tool brands in the world with our high standard private labeling services. The quality of our tool is also excellent. This straight edge tool requires a very low tolerance so the straight edge can be, clear enough, straight. You wouldn’t want to buy a tool to check what’s wrong with your car, but eventually to find out that the tool is wrong, not the car.

This tool is a great helper if your job is constantly related to engine disassembling and remodelling. We ship internationally and we provide discounts when you purchase in bulk. It’s also not a problem if you are looking to put your logo on the tool and that becomes your tool. Just drop us a line and we will talk from there.

| Package | Blow molded case (blue) | |

| Packing | 5 sets in a master carton | |

| Weight per set | 2.4 kg | 5.4 lbs |

| Net weight per carton | 12.2 kg | 26.8 lbs |

| Gross weight per carton | 13.0 kg | 28.6 lbs |

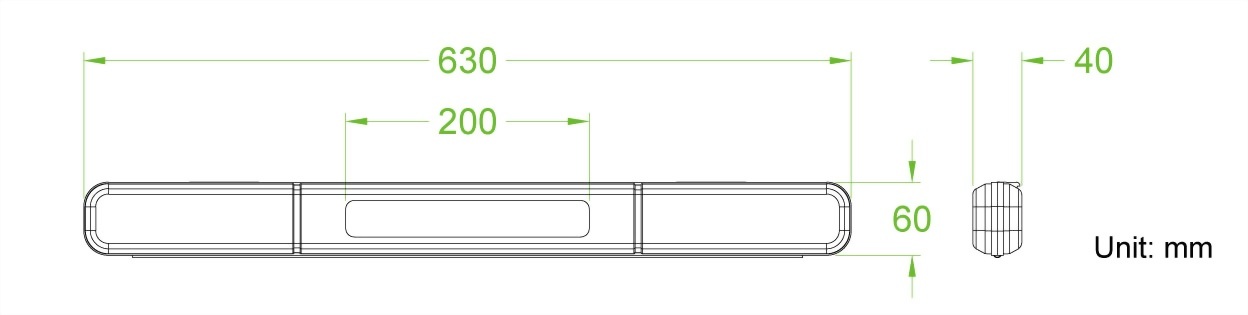

| Size per set | 63 × 6 × 4 cm | 24.8 × 2.36 × 1.57 inch |

| Size per carton | 64 × 22 × 8 cm | 17.3 × 14.6 × 14.6 inch |

| Volume per carton | 0.011 CBM | 0.4 CUFT |

| Case label size | 19.8 × 3.0 cm | 7.8 × 1.2 inch |

| Suggested HS code |

90153000009 |

| MOQ with laser marking | 10 sets |

| MOQ without laser marking | 5 sets |

| Laser marking cost | + TWD 8 |