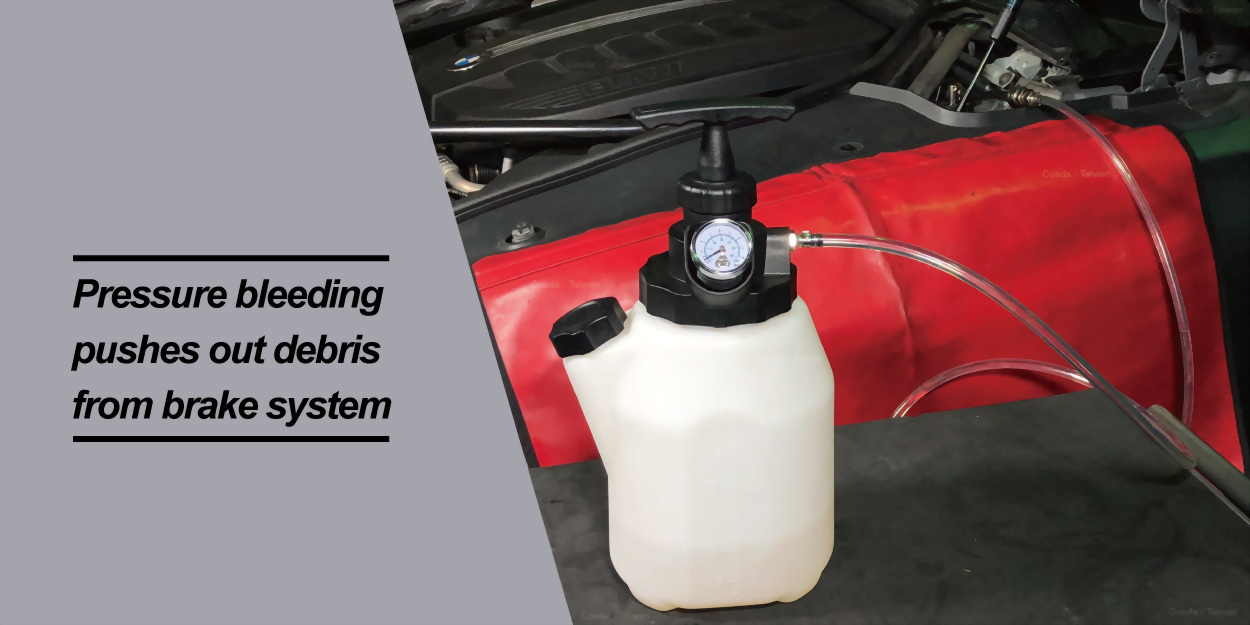

Brake Pressure Bleeder Set (3 Liter)

• Efficient in pushing out debris from brake system

• 3-liter / 3.17-quart tank with a safety pressure relief valve

• Suitable for changing DOT 3, DOT 4, and DOT 5.1 brake fluids, but NOT SUITABLE for changing DOT 5

• Includes a standard European adapter with a swivel 90° fitting to tackle limited space

• One-way valve is fitted in the hose end connector to prevent unsafe brake fluid spills after disconnecting the hose from master cylinder

Pressure bleeding has become more and more popular in recent years. There are a lot of YouTubers sharing their brake fluid changing process by using pressure bleeding method. It doesn't mean that the conventional method, i.e. having one person in the car depressing the brake pedal and another person standing by the wheel cylinders to wait for the used brake fluid to come out, is dying, or the vacuum brake bleeding process is unfavorable now. Instead, the pressure bleeding approach provides a great alternative for people who want to change brake fluid in a secure and risk-free manner.

In contrast to the conventional manner to bleed brake fluid, pressure bleeding exercises pressure to push the new brake fluid in, and gradually to push old brake fluid out via the brake bleeder valves on the wheel cylinders. This method can guarantee that no air will be re-introduced to the wheel cylinders via the small gaps of the loosened brake bleeder valves. In addition, all this can be done by just one person.

Usually there are two types of pressure bleeder tools on the market, one is manual, and the other is pneumatic. Both are fine but the only risk for the pneumatic method is that everything goes very fast. If the tank is running out of brake fluid to introduce into the brake master cylinder reservoir, then air will be pushed into the brake cylinder in a blink of eye. The manual method may be slower, but more secure.

So how does it work? First, pour new brake fluid into the tank by opening the side cap on the tank. The side cap provides an easy access to the tank so you will not have to open the top cap. The constant opening and closing may damage the seal inside the top cap or the threads on the tank opening. After refilling the tank with a proper amount of brake fluid, fasten the side cap back. Connect the threaded adapter provided to the master cylinder reservoir, and then connect the tail of the threaded adapter to the hose end from the tank. The threaded adapter is the standard size for almost all European vehicles, also suitable for some Cadillac, Ford, and Mazda. Check the adapter is securely connected to the reservoir, and then pump the tank manually to let the pressure to build up. Stop pumping when the pressure reaches 0.5 bar or 7 psi and leave the tank slightly pressurized for about 10 minutes. This step is to see if there are any tiny leaks around the reservoir. If there are small leaks, connect the adapter again more securely. If no leaks are found, simply continue pumping the tank to 1 bar or 14.5 psi, and the new brake fluid will be introduced into the brake system.

Go to the wheel that is the most distant from the brake reservoir and loosen the brake bleeder valve. The pressure remained in the brake system will push the old brake fluid out of the system when the brake bleeder valve is unfastened. Wait until the color changes in the bleeding tube or when the air bubbles are no longer visible, and then you can go on to do the same to other wheels. The sequence of the bleeding wheel cylinders shall be found in the service manual. After bleeding all four wheels, go back to the tank, press the pressure release button to let the pressure release. Disconnect the adapter from the master cylinder reservoir and use a rug around the filler neck when disconnecting, in case that there are any brake fluid that drips from the adapter and may damage the car paint, or any remaining pressure in the reservoir that may cause the brake fluid to gush out. Check the volume in the reservoir, and clean the filler neck, and the work is done.

This tool set is designed and manufactured by Cosda Manufacturing Company, the most innovative tool manufacturer in Taiwan. Cosda is specializing producing high quality tools for major tool brands in the world, and we provide B2B private branding services with high standards. Please feel free to contact us to let us know if there are anything that we can cooperate together and provide a great solution for the current market. We look forward to hearing from you.

| Package | Carton box + label | |

| Packing | 4 sets in a master carton | |

| Weight per set | 2.8 kg | 6.2 lbs |

| Net weight per carton | 11.2 kg | 24.6 lbs |

| Gross weight per carton | 12.2 kg | 26.8 lbs |

| Size per set | 27.5 × 23.5 × 42.5 cm | 10.8 × 9.3 × 16.7 inch |

| Size per carton | 57.8 × 49.4 × 45.0 cm | 22.7 × 19.4 × 17.7 inch |

| Volume per carton | 0.128 CBM | 4.6 CUFT |

| Suggested HS code |

84132000001 |

| MOQ without logo printing | 6 sets |

| Logo printing cost | + TWD 10 with an MOQ of 100 sets |

| Logo printing tooling cost | + TWD 2,000 |

|

Not for sale in |

China, Ireland, and the UK |