Blind Hole Bearing Puller and Slide Hammer Set (16 pcs)

• Includes a slide hammer and a puller

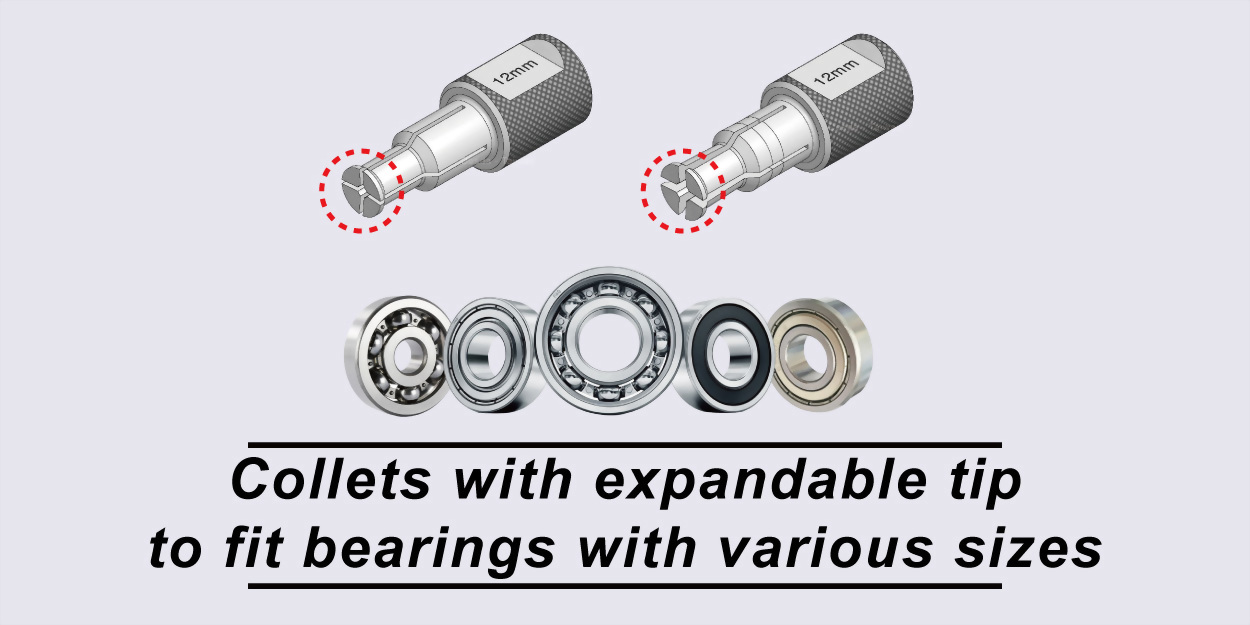

• Provided with adapters that can be expanded within the blind hole for stronger connection

A blind hole bearing refers to a type of bearing that is installed in a blind hole—a hole that does not go all the way through a material or component, meaning it has a bottom or closed end. Unlike through holes, where a bearing can be pushed out from the opposite side, blind holes require special techniques for bearing installation and removal because access is only available from one side.

Key Characteristics of a Blind Hole Bearing:

1. Installation Challenges: Since the hole does not go all the way through, inserting the bearing requires precise alignment and often specialized tools to press or pull the bearing into place without damaging it.

2. Removal Difficulty: Removing a bearing from a blind hole is more challenging because you cannot simply push it out from the other side. Specialized pullers or other removal tools are often used to extract the bearing from the blind hole.

3. Applications: Blind hole bearings are commonly used in situations where space constraints or design requirements prevent a through-hole from being used. They are often found in machinery, automotive components, and various types of equipment where compact or enclosed designs are needed.

4. Types of Bearings Used: The term "blind hole bearing" doesn't refer to a specific type of bearing but rather to the condition under which any standard bearing (e.g., ball bearings, roller bearings, sleeve bearings) is installed in a blind hole.

Overall, blind hole bearings require careful handling and specific tools for both installation and removal due to the limited access provided by the blind hole.

Removing and installing bearings in a blind hole requires specialized tools designed to handle the unique challenges presented by the limited access. Here are some commonly used tools for both the removal and installation of blind hole bearings:

Removal Tools:

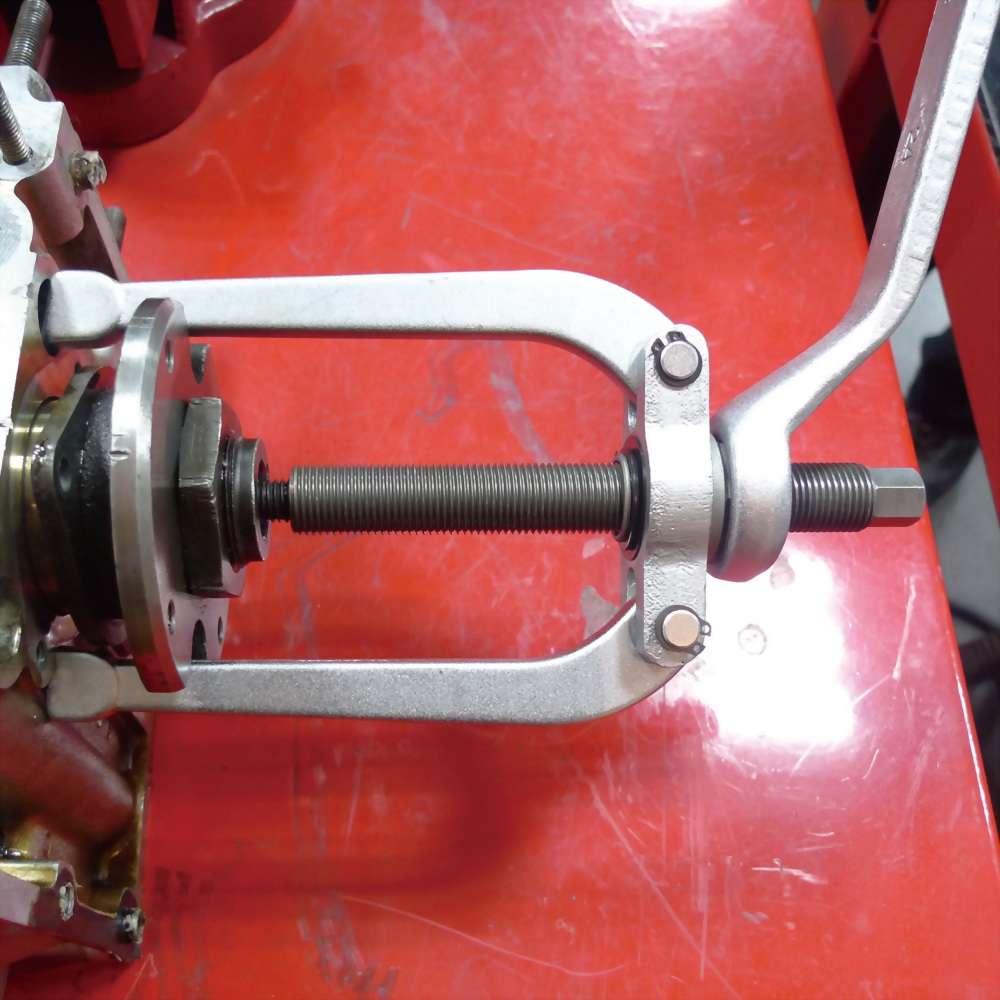

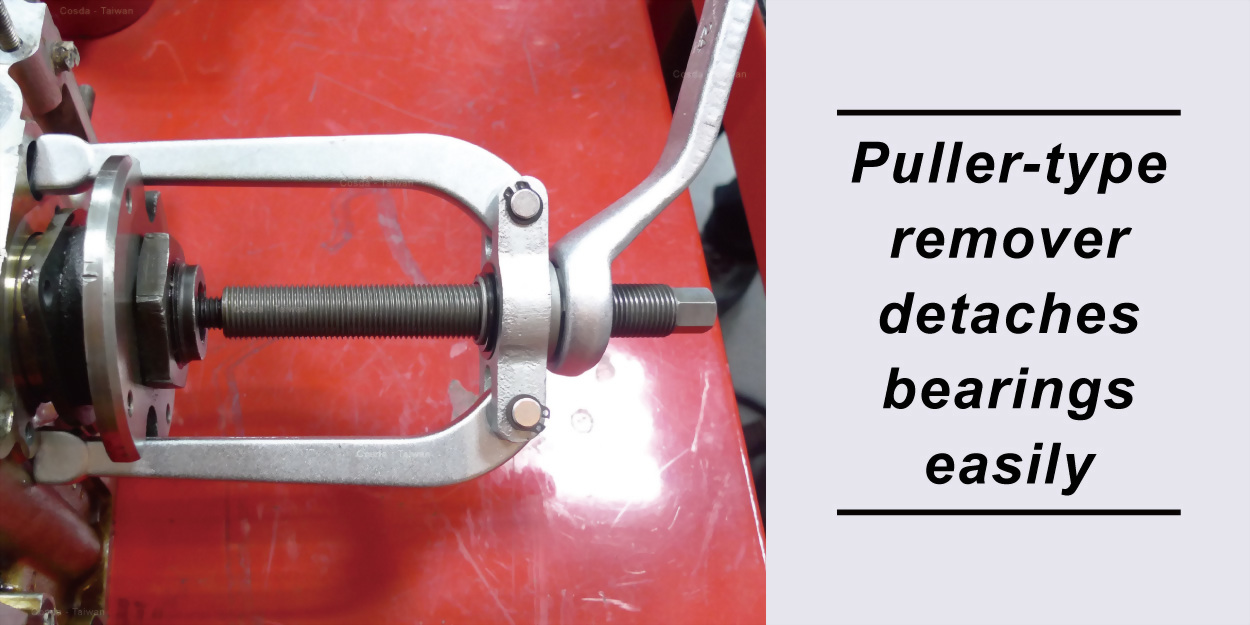

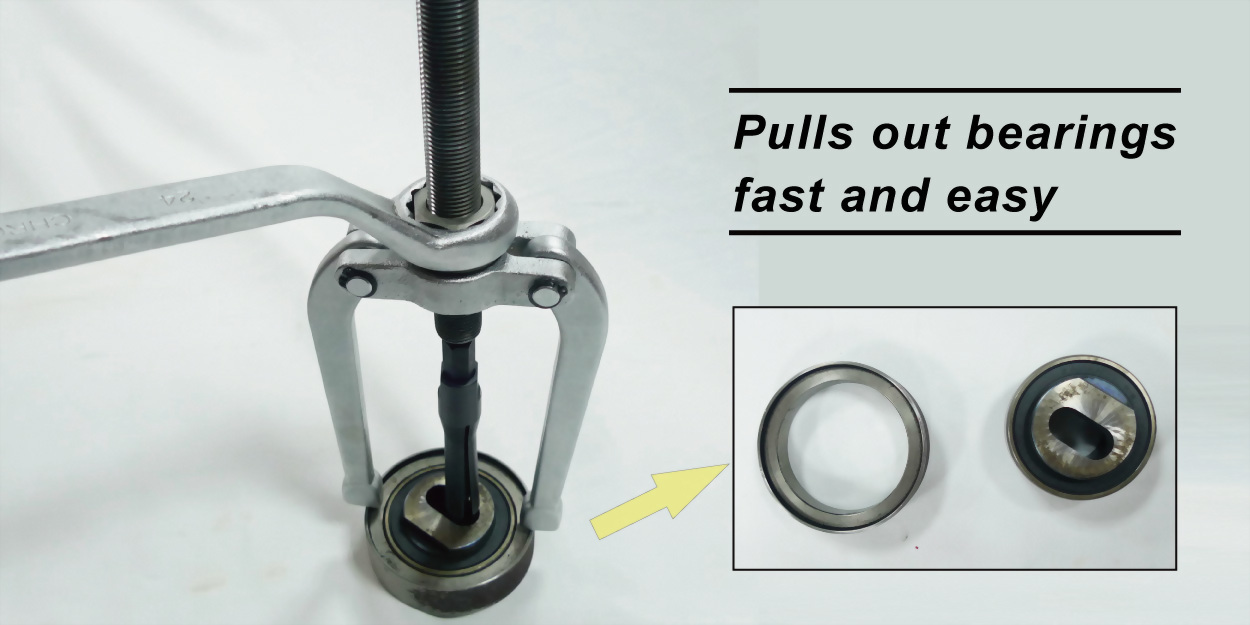

1. Blind Hole Bearing Puller:

- This tool consists of a collet that expands inside the bearing's inner race when a screw is tightened. Once the collet is securely gripping the bearing, a slide hammer or a threaded rod with a weight is used to pull the bearing out of the blind hole.

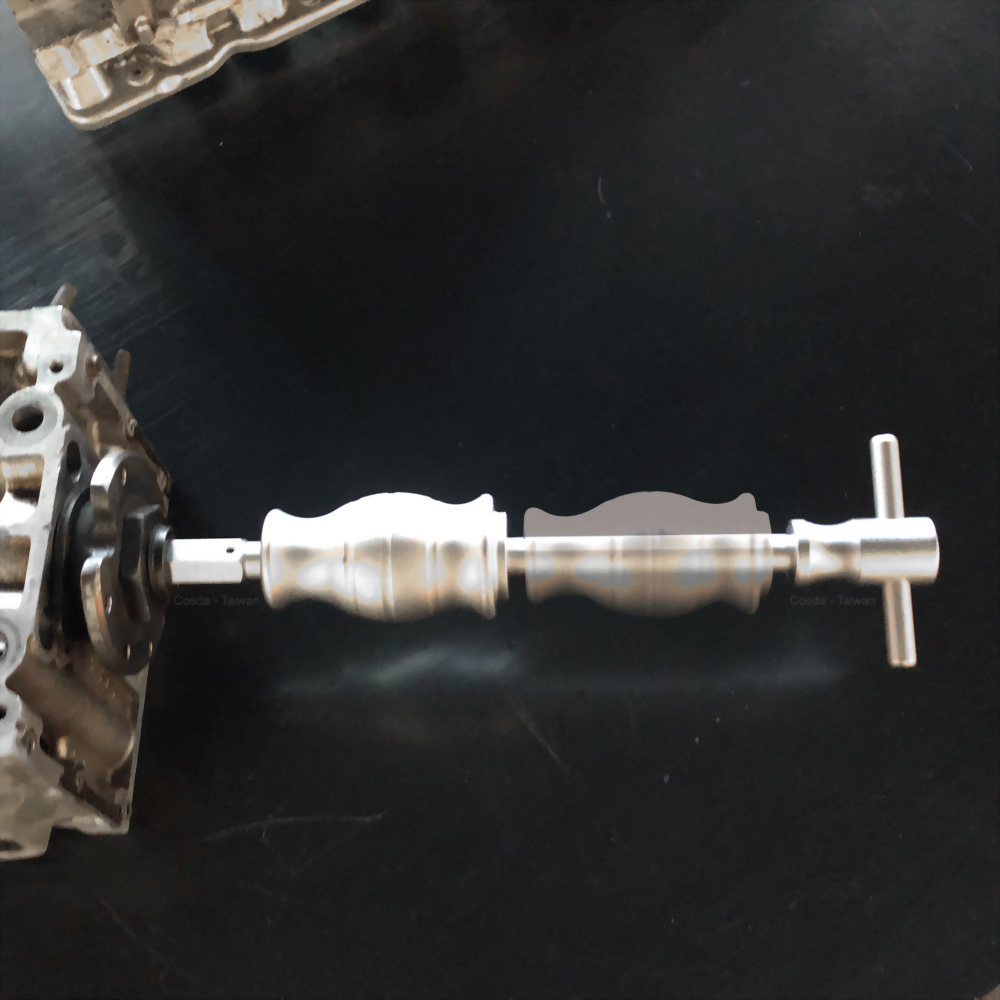

2. Slide Hammer with a Blind Hole Adapter:

- A slide hammer is attached to an adapter that fits inside the bearing. The slide hammer's impact force is then used to pull the bearing out. This method is often used for smaller bearings.

3. Internal Bearing Puller Set:

- This set includes various sized pullers designed to fit different bearings. The puller grips the bearing from the inside, and the tool is then used to extract the bearing. This is especially useful for bearings in deep or narrow blind holes.

4. Hydraulic Puller:

- For larger or more stubborn bearings, a hydraulic puller can be used. It applies hydraulic pressure to remove the bearing, providing more force than a manual puller.

Installation Tools:

1. Bearing Press:

- A bearing press is used to apply even pressure to press the bearing into the blind hole. The press typically uses a set of dies or arbors that match the size of the bearing, ensuring that the bearing is seated correctly without causing damage.

2. Bearing Driver Set:

- This set includes various sizes of drivers that match the bearing's diameter. The driver is placed against the bearing and tapped with a mallet to press the bearing into place evenly. This method ensures that force is applied uniformly across the bearing's surface.

3. Heat Installation Method:

- In some cases, heating the bearing housing (or cooling the bearing) can expand the metal slightly, allowing the bearing to be installed with less force. Once the temperature equalizes, the bearing is securely held in place by the housing's contraction.

4. Hydraulic Press:

- A hydraulic press can be used for more precise control when pressing a bearing into a blind hole. This tool allows for slow, controlled pressure, reducing the risk of damaging the bearing or the housing.

5. Arbor Press:

- Similar to a hydraulic press, an arbor press can be used for installing bearings into a blind hole. It provides a more controlled application of force than manual methods and is suitable for smaller bearings.

General Tips for Blind Hole Bearing Installation and Removal:

- Lubrication: Lightly lubricating the bearing and the housing can make installation easier and reduce the risk of damage.

- Alignment: Ensure the bearing is aligned correctly with the hole to avoid misalignment or damage during installation.

- Precision Tools: Using tools specifically designed for the size and type of bearing is essential to avoid damaging the bearing or the surrounding components.

These tools help ensure that bearings are removed and installed correctly without damaging the bearing or the blind hole.

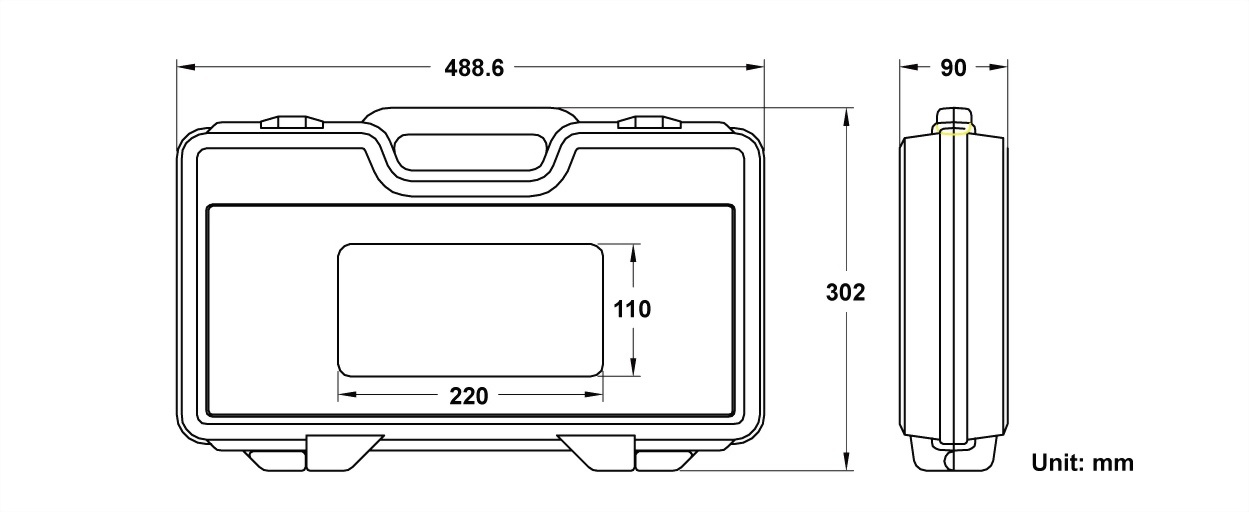

| Package | Blow molded case (red) | |

| Packing | 4 sets in a master carton | |

| Weight per set | 5.1 kg | 11.3 lbs |

| Net weight per carton | 20.5 kg | 45.1 lbs |

| Gross weight per carton | 21.5 kg | 47.3 lbs |

| Size per set | 48.9 × 30.2 × 9.0 cm | 19.2 × 11.9 × 3.5 in |

| Size per carton | 51.0 × 37.5 × 32.0 cm | 20.1 × 14.8 × 12.6 in |

| Volume per carton | 0.061 CBM | 2.2 CUFT |

| Case label size | 22.0 × 11.0 cm | 8.7 × 4.3 in |

| No. | Image | Cosda No. | Description | |

|---|---|---|---|---|

| 1 |  |

SD-1029-1 | Puller | More |

|

|

||||

| 2 |  |

SD-1029-2 | Slide Hammer | More |

|

|

||||

| 3 |  |

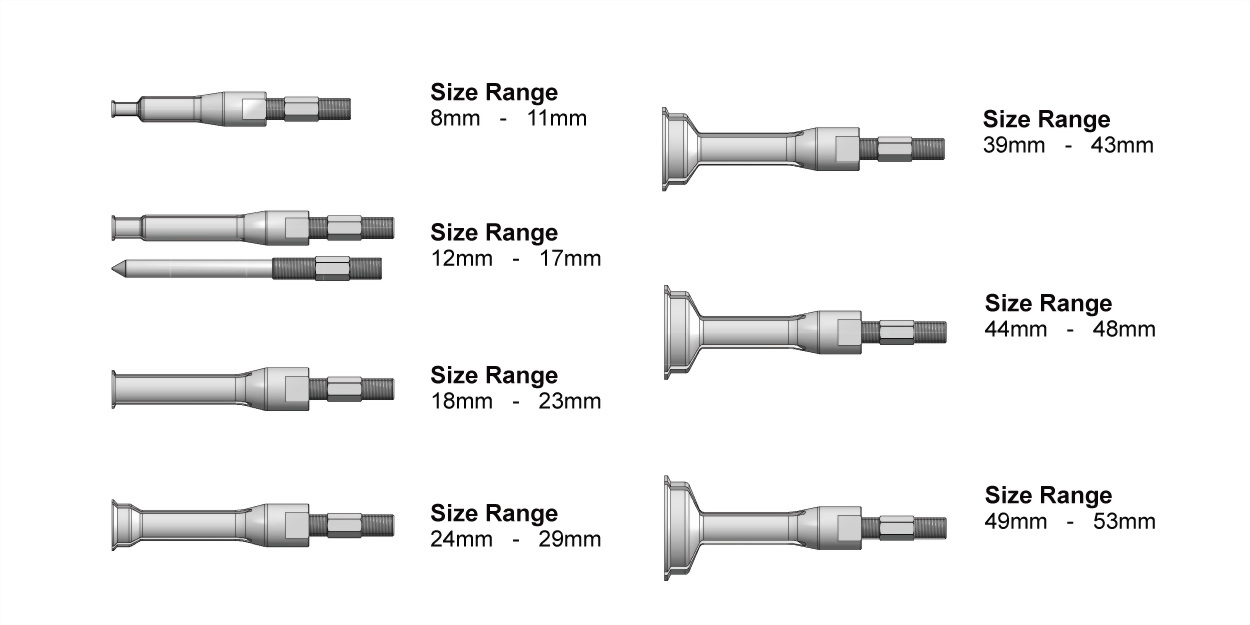

SD-1029-3A | M8-11 Collet | More |

|

|

||||

| 4 |  |

SD-1029-3B | M12-17 Collet | More |

|

|

||||

| 5 |  |

SD-1029-19 | Ø8-12mm Stick | More |

|

|

||||

| 6 |  |

SD-1029-3C | M18-23 Collet | More |

|

|

||||

| 7 |  |

SD-1029-3D | M24-29 Collet | More |

|

|

||||

| 8 |  |

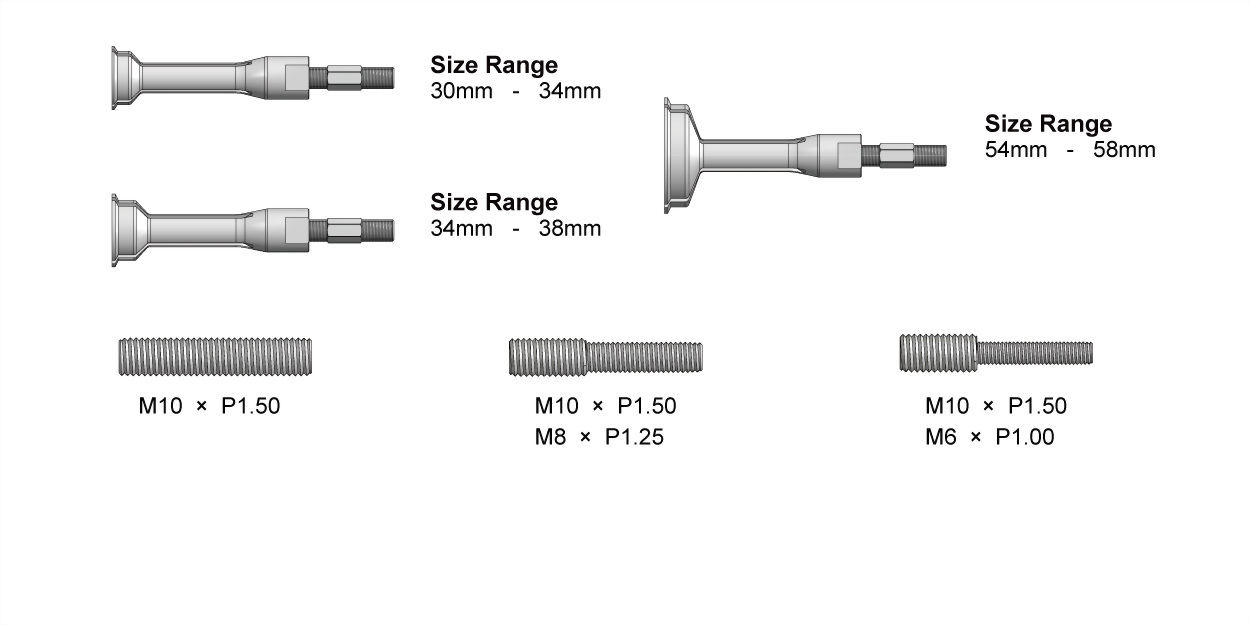

SD-1029-3E | M30-34 Collet | More |

|

|

||||

| 9 |  |

SD-1029-3F | M34-38 Collet | More |

|

|

||||

| 10 |  |

SD-1029-3G | M39-43 Collet | More |

|

|

||||

| 11 |  |

SD-1029-3H | M44-48 Collet | More |

|

|

||||

| 12 |  |

SD-1029-3I | M49-53 Collet | More |

|

|

||||

| 13 |  |

SD-1029-3J | M54-58 Collet | More |

|

|

||||

| 14 |  |

SD-1029-20 | M10 connector | More |

|

|

||||

| 15 |  |

SD-1029-21 | M8 Connector | More |

|

|

||||

| 16 |  |

SD-1029-22 | M6 Connector | More |

| Suggested HS code |

82055990909 |

| MOQ with laser marking | 20 sets |

| MOQ without laser marking | 4 sets |

| Laser marking cost | + TWD 6 on slide hammer and puller, + TWD 3 on adapters |