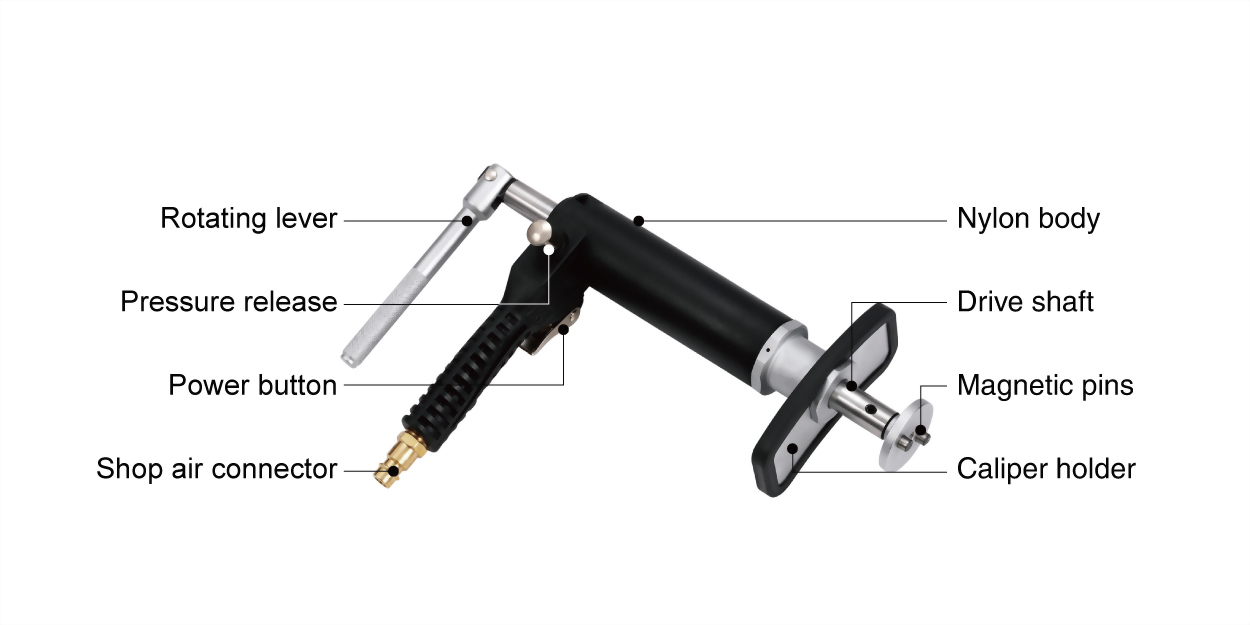

Air Powered Brake Caliper Piston Wind Back Tool Set (23 pcs)

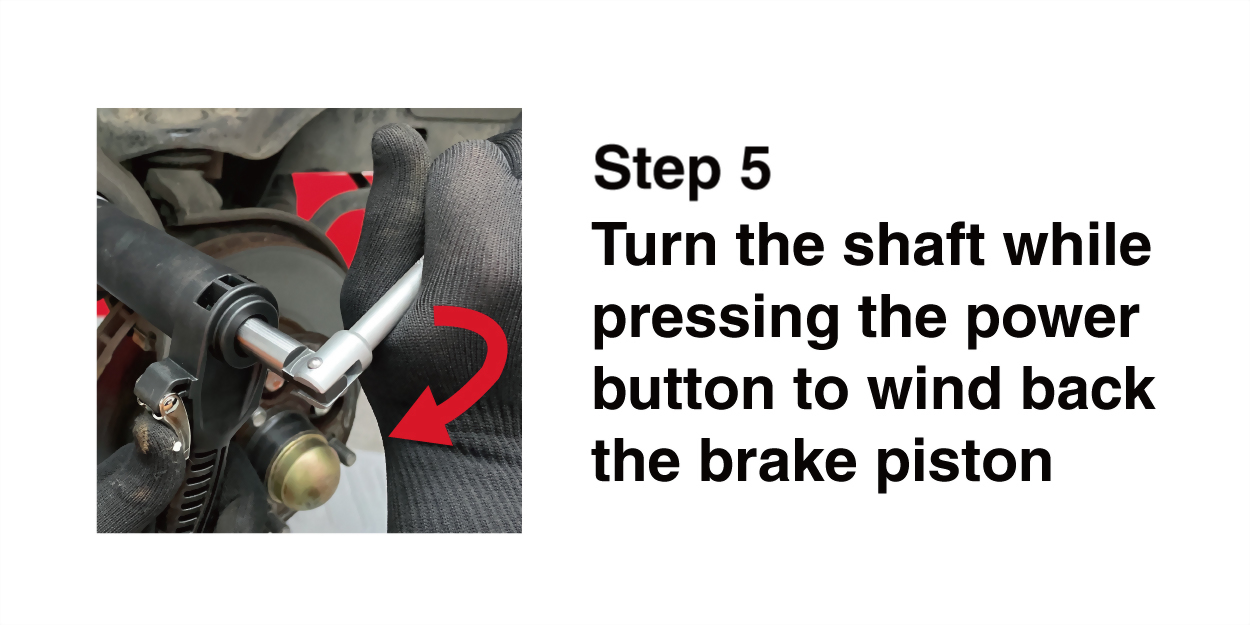

• Tool can be turned left- and right-ward - suitable for regular and reverse-threaded pistons

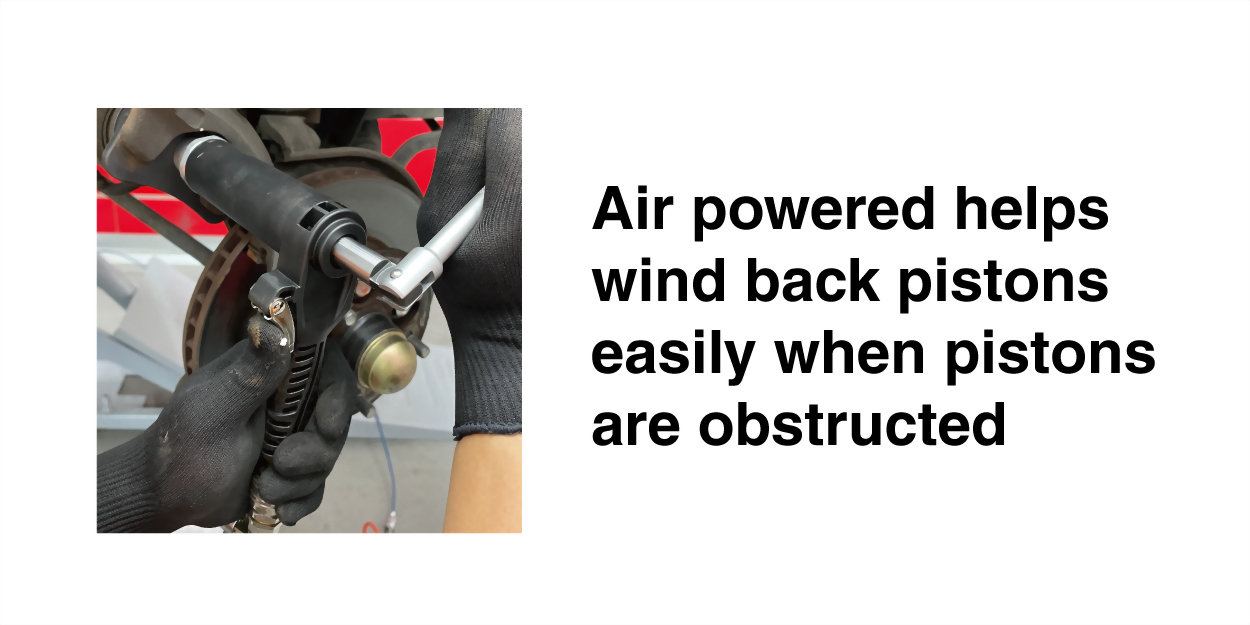

• Pneumatic powered tool is able to wind pistons back simply pressing a button

• Includes 22 adapters, fitting a wide range of vehicles

What is an Electric Parking Brake System?

An Electric Parking Brake (EPB) system is a modern vehicle feature that replaces the traditional mechanical handbrake or foot-operated parking brake with an electronically controlled system. The EPB system uses electronic controls and actuators to engage or disengage the parking brake.

Key Components:

1. Electronic Control Unit (ECU): The brain of the system, which processes signals from the driver (e.g., pressing a button) and commands the actuators to engage or disengage the brakes.

2. Actuators: These are electric motors or solenoids that apply force to the brake calipers or drum brakes to hold the vehicle in place.

3. Sensors: Various sensors monitor the position of the parking brake, the vehicle's speed, and other factors to ensure proper operation.

4. Driver Interface: Usually a button or switch on the dashboard or center console that the driver uses to activate or deactivate the parking brake.

How It Works:

- Engaging the Brake: When the driver presses the EPB button, the ECU sends a signal to the actuators, which then apply force to the brake calipers or drum brakes, securing the vehicle in place.

- Disengaging the Brake: When the button is pressed again, or in some cases, when the driver starts driving (automatic release), the actuators release the brakes, allowing the vehicle to move.

Advantages:

- Space Saving: Eliminates the need for a mechanical lever or pedal, freeing up cabin space.

- Improved Safety: Can include features like automatic engagement when the vehicle is turned off or in the event of a system failure.

- Convenience: Easier to engage/disengage, often integrating with other vehicle systems (e.g., hill start assist).

- Integration with Other Systems: Can be integrated with features like automatic hold or hill start assist.

Disadvantages:

- Complexity: More complex than traditional systems, requiring specialized knowledge for repairs.

- Cost: Generally more expensive to repair or replace than mechanical systems.

EPB systems are increasingly common in modern vehicles, especially in mid-to-high-end models.

How can we wind back the piston on EPB systems?

Winding back the piston on an Electric Parking Brake (EPB) system requires a specific procedure due to the electronic controls involved. The process typically involves using either the vehicle’s built-in controls or a diagnostic tool to retract the piston. Here’s how you can do it:

1. Using Built-In Controls:

Some vehicles allow you to retract the EPB piston using the vehicle's own controls, without the need for additional tools.

- Step 1: Turn on the Ignition: Make sure the vehicle is on, but the engine is not running.

- Step 2: Release the Parking Brake: Ensure the EPB is disengaged.

- Step 3: Activate Maintenance Mode:

- Method A: On some vehicles, you can engage a maintenance mode by pressing and holding the EPB switch while performing specific actions (e.g., pumping the brake pedal or pressing the accelerator). Check the vehicle’s manual for exact instructions.

- Method B: Follow the specific button sequence, which could involve holding the EPB button while turning the ignition on or pressing the brake pedal in a specific pattern.

- Step 4: Retract the Pistons: Once in maintenance mode, the EPB pistons will retract, allowing you to service the brakes.

- Step 5: Turn Off Maintenance Mode: After the brake job, deactivate maintenance mode following the same procedure in reverse.

2. Using a Diagnostic Tool:

For vehicles that don’t support manual retraction via built-in controls, or for added precision, you can use an automotive diagnostic tool.

- Step 1: Connect the Diagnostic Tool: Plug the diagnostic tool into the vehicle's OBD-II port.

- Step 2: Access the EPB Menu: Navigate through the tool’s interface to find the Electronic Parking Brake menu.

- Step 3: Select the Piston Retract Function: Follow the on-screen prompts to retract the EPB pistons. This process electronically disengages the parking brake and retracts the pistons, allowing you to perform brake maintenance.

- Step 4: Perform Brake Service: With the pistons retracted, you can now change brake pads or perform other necessary maintenance.

- Step 5: Re-engage the Pistons: After completing the brake work, use the diagnostic tool to command the EPB system to re-engage the pistons and exit service mode.

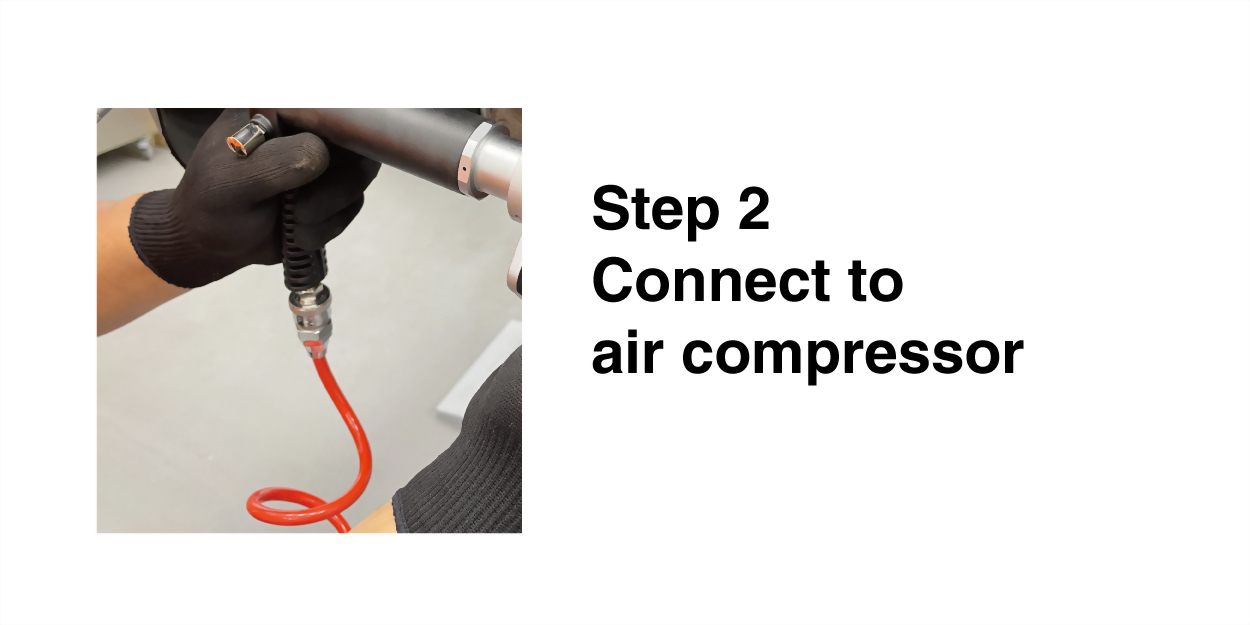

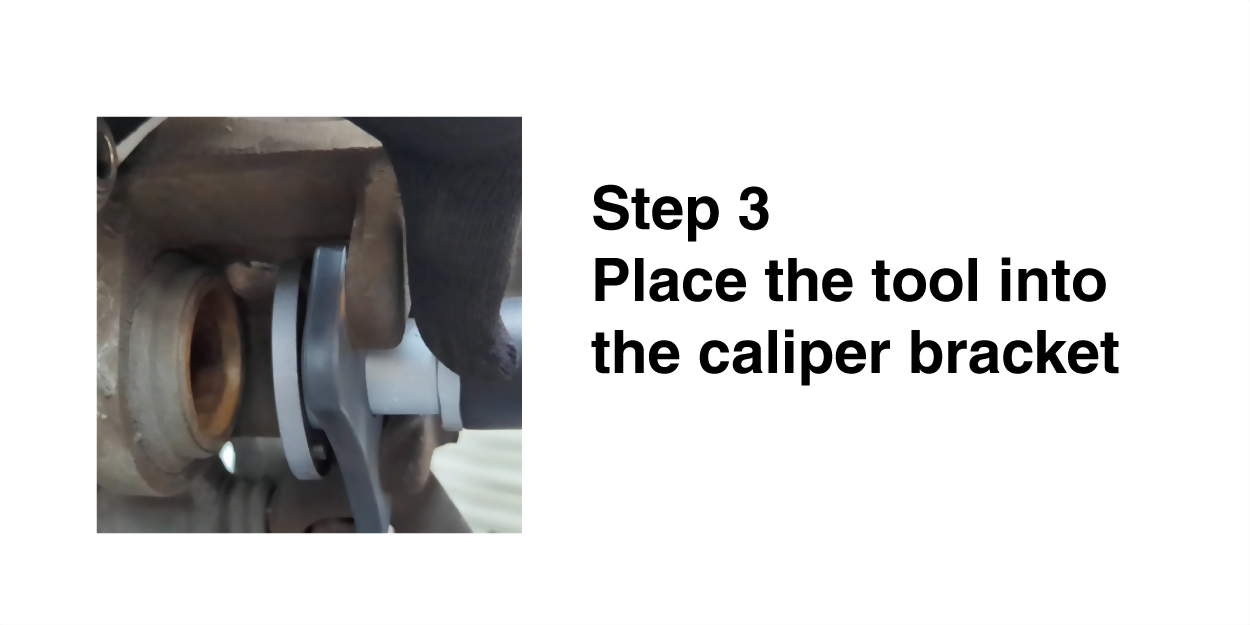

3. Manual or Pneumatic Wind-Back Tool (just as Cosda’s SD-1350R)l:

In some cases, if you don’t have access to a diagnostic tool, a manual wind-back tool can be used.

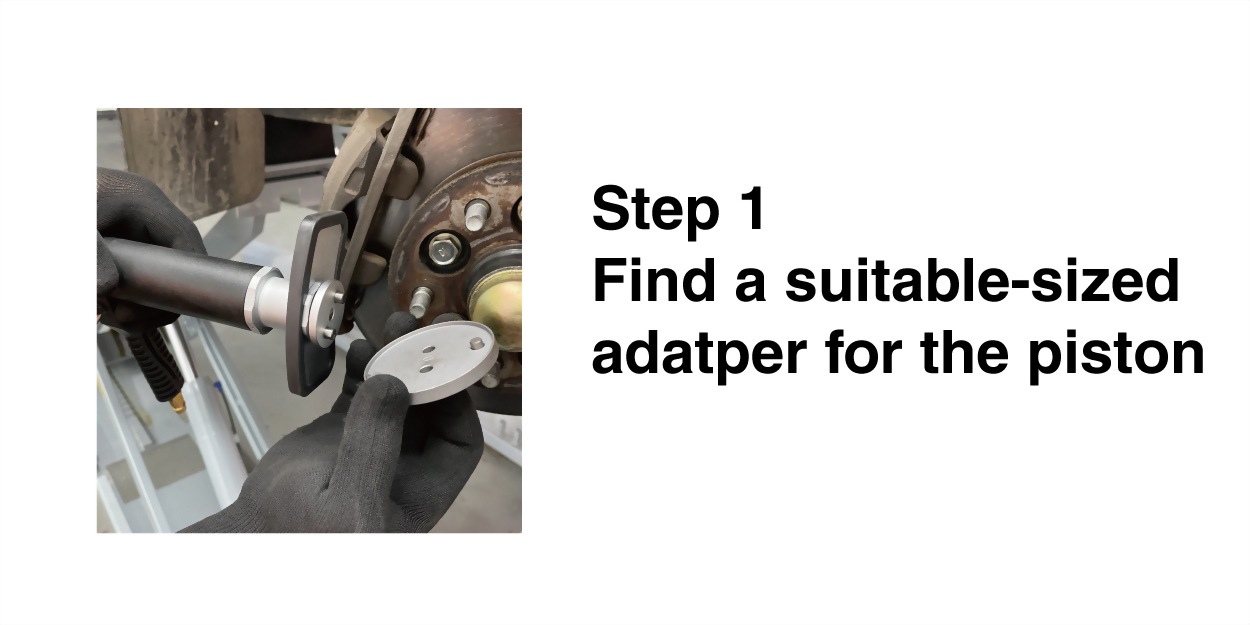

- Step 1: Disconnect the EPB Motor: Unplug the motor connected to the EPB.

- Step 2: Use a Wind-Back Tool: Manually retract the piston using a suitable wind-back tool (specific to your brake caliper type).

- Step 3: Reconnect the Motor: Once the brake work is done, reconnect the EPB motor.

Caution:

- Ensure Battery Stability: Since the EPB system is electronically controlled, make sure the battery is stable and fully charged to avoid malfunctions during the process.

- Follow Manufacturer Guidelines: Always consult the vehicle’s manual for specific instructions related to your make and model.

EPB systems are sensitive, and incorrect procedures can lead to faults or system errors. If unsure, it’s always best to consult with or refer the task to a professional technician.

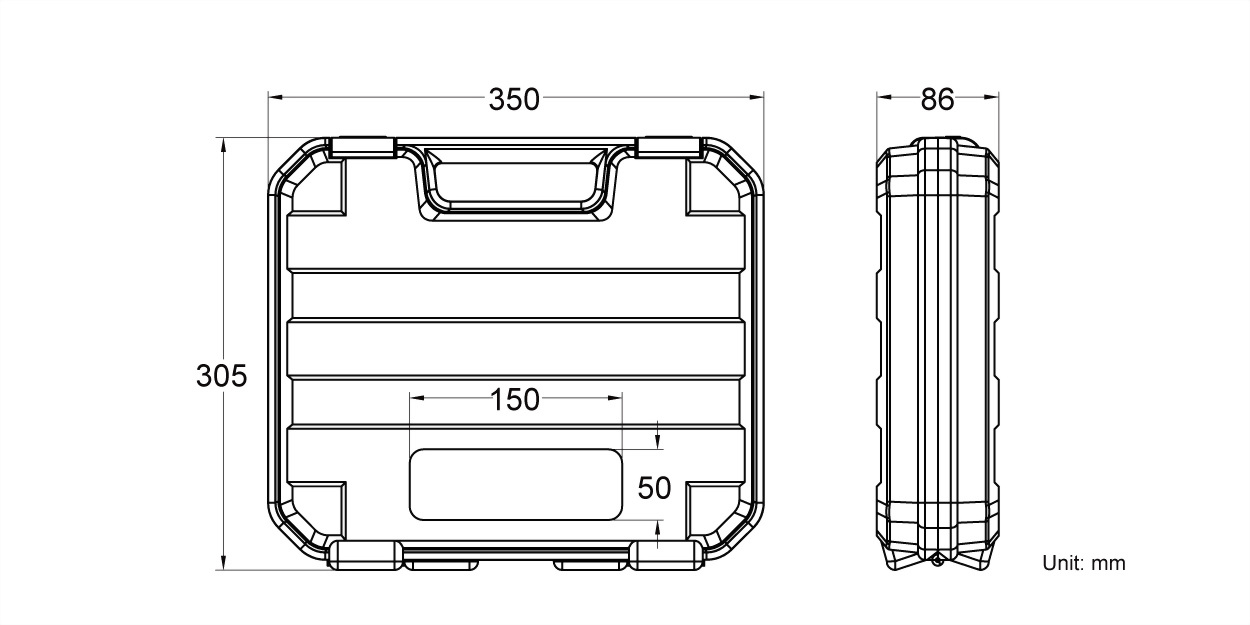

| Package | Blow molded case (red) | |

| Packing | 5 sets in a master carton | |

| Weight per set | 2.8 kg | 6.2 lbs |

| Net weight per carton | 13.8 kg | 30.3 lbs |

| Gross weight per carton | 14.8 kg | 32.6 lbs |

| Size per set | 35.0 × 30.5 × 8.6 cm | 13.8 × 12.0 × 3.4 inch |

| Size per carton | 47.0 × 36.5 × 33.0 cm | 18.5 × 14.4 × 13.0 inch |

| Volume per carton | 0.057 CBM | 2.0 CUFT |

| Case label size | 15.0 × 5.0 cm | 5.9 × 2.0 inch |

| No. | Image | Cosda No. | Description | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 |  |

SD-1350-01 | Air Powered Brake Caliper Piston Wind Back Tool | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 |  |

SD-1050-0 | Brake Disc No. 0 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 |  |

SD-1050-02 | Brake Disc No. 2 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 |  |

SD-1050-03 | Brake Disc No. 3 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 |  |

SD-1050-04 | Brake Disc No. 4 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 |  |

SD-1050-05 | Brake Disc No. 5 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 |  |

SD-1050-06 | Brake Disc No. 6 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 |  |

SD-1050-07 | Brake Disc No. 7 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 |  |

SD-1050-08 | Brake Disc No. 8 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 |  |

SD-1050-09 | Brake Disc No. 9 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11 |  |

SD-1050-A | Brake Disc A (Z) | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 |  |

SD-1050-B1 | Brake Disc B1 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 13 |  |

SD-1050-B2 | Brake Disc B2 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

- Vehicle fitment

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 |  |

SD-1050-B3 | Brake Disc B3 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 15 |  |

SD-1050-B4 | Brake Disc B4 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

- Vehicle fitment

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16 |  |

SD-1050-B5 | Brake Disc B5 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

- Vehicle fitment

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 |  |

SD-1050-E | Brake Disc E | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18 |  |

SD-1050-F | Brake Disc F (G) | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 19 |  |

SD-1050-K | Brake Disc K | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 |  |

SD-1050-K1 | Brake Disc K1 | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 21 |  |

SD-1050-M | Brake Disc M | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 |  |

SD-1050-N | Brake Disc N | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 23 |  |

SD-1050-W | Brake Disc W | More |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

- Specifications

- Vehicle fitment

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Suggested HS code |

82055990909 |

| MOQ with laser marking | 10 sets |

| MOQ without laser marking | 5 sets |

| Laser marking cost | +TWD 2 on brake discs |

| MOQ with logo printing | 100 sets |

| Logo printing cost | + TWD 5 on pneumatic tool, +TWD 2,500 for tooling cost |

This product holds patents and CE certificate, tested by SGS