Wheel Hub Grinder Set

brake drums before reassembling.

• Helps prevent bad balancing or bad bolt tightening torque due to corroded surfaces.

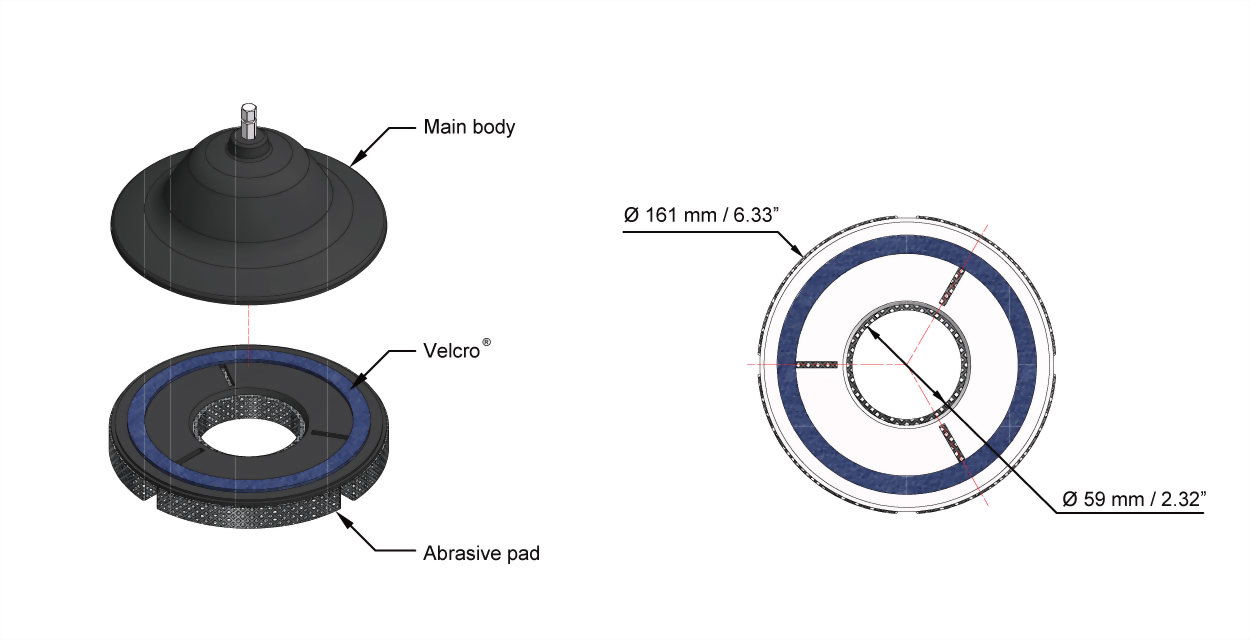

• Suitable for stud-less wheel surfaces, commonly found on European vehicles, with wheel hub diameter between 60 and 160 mm

• Work with impact drivers and cordless screwdrivers with 8 mm female drive

Using a grinder to polish rust and debris on wheel hubs and drums is important for several reasons:

1. Surface Preparation: A clean, smooth surface is crucial for proper function and safety. Rust and debris can cause poor contact with brake components, leading to decreased performance.

2. Prevent Corrosion: Rust can spread and worsen if not removed. Polishing helps prevent further corrosion and extends the life of the components.

3. Improved Brake Performance: A polished surface allows for better seating of brake pads and shoes, improving braking efficiency and reducing noise.

4. Visual Inspection: Cleaning the surface makes it easier to inspect for cracks, wear, or other damage that might not be visible under rust or grime.

5. Adhesion for Coatings: If you plan to apply any protective coatings, a polished surface ensures better adhesion, helping to protect against future rust.

Using a grinder allows for efficient material removal, especially for stubborn rust, making the process quicker and more effective than manual methods.

| Package | Neutral white box with a label | |

| Packing | 40 sets in a master carton | |

| Weight per set | 465 g | 1 lbs |

| Net weight per carton | 18.6 kg | 40.9 lbs |

| Gross weight per carton | 20 kg | 44 lbs |

| Size per set | 16.5 × 16.5 × 11.5 cm | 6.5 × 6.5 × 4.5 inch |

| Size per carton | 82.5 × 46 × 33 cm | 32.5 × 18 × 13 inch |

| Volume per carton | 0.125 CBM | 4.4 CUFT |

| Suggested HS code |

82059000008 |

| MOQ with laser marking | 120 sets |

| MOQ without laser marking | 40 sets |

| Laser marking cost | + TWD 5 on each piece |