Stud Removal Tools in Metrics Sizes (8 pcs)

• Includes the most common stud sizes in metric sizes:

M6×P1.0, M8×P1.25, M10×P1.25, M10×P1.5

• Special steel ball design provides energy-saving way of installing new studs

The studs are a common fastener in areas such as intake/exhaust manifolds, but removing the studs can be a headache unless you have the right tool to do it. The studs are the bolts but without the nut top. There are only threads exposed so the most common ways to remove the studs are to destroy it by yanking it out with force (which is not always possible), the traditional two nuts locking method, or using the right tool that is specifically designed for removing and installing studs.

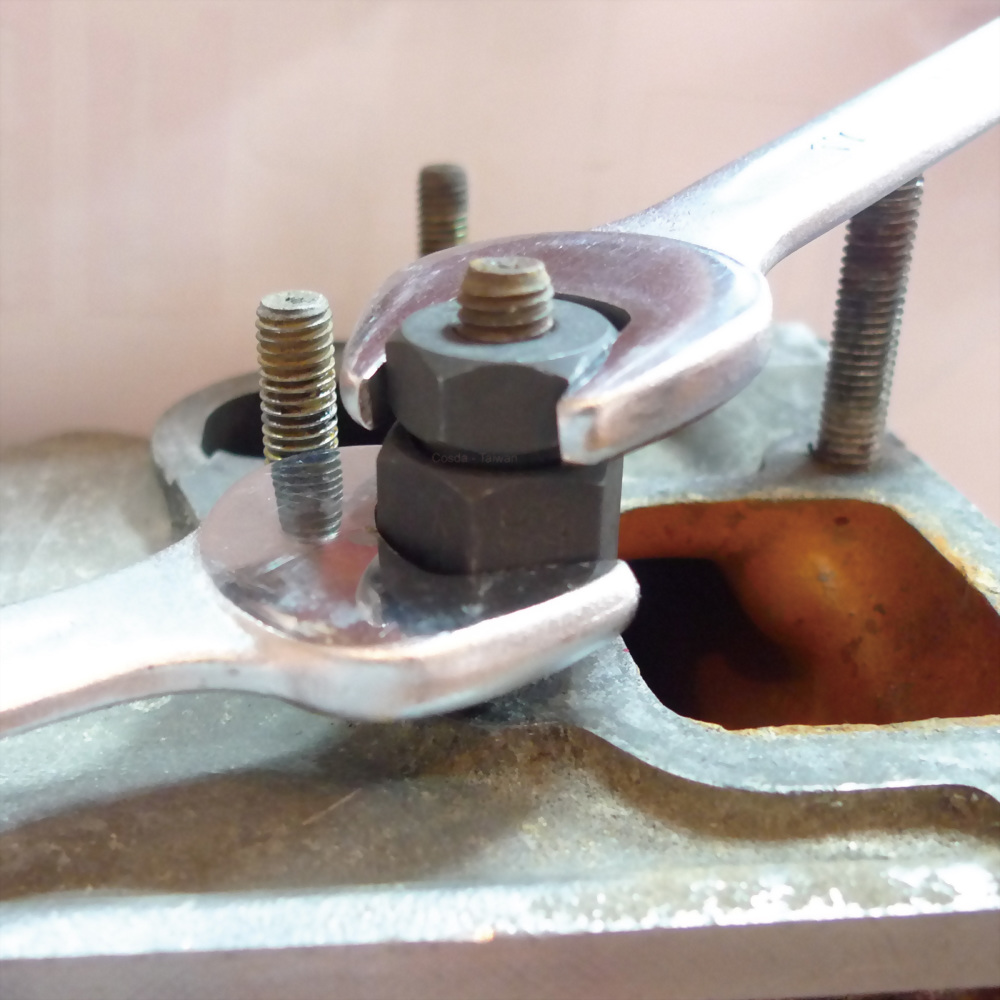

This tool set has eight units included, the upper four units are stud installers and the lower four units are stud removers. First you will want to find the right size for the remover that matches the size of the stud you are going to remove. Screw the remover to the stud. Use two wrenches to lock the two nuts tightly together in opposite directions. The remover now is grabbing the stud tightly. Turn the lower nut anti clockwise and the stud will be removed accordingly.

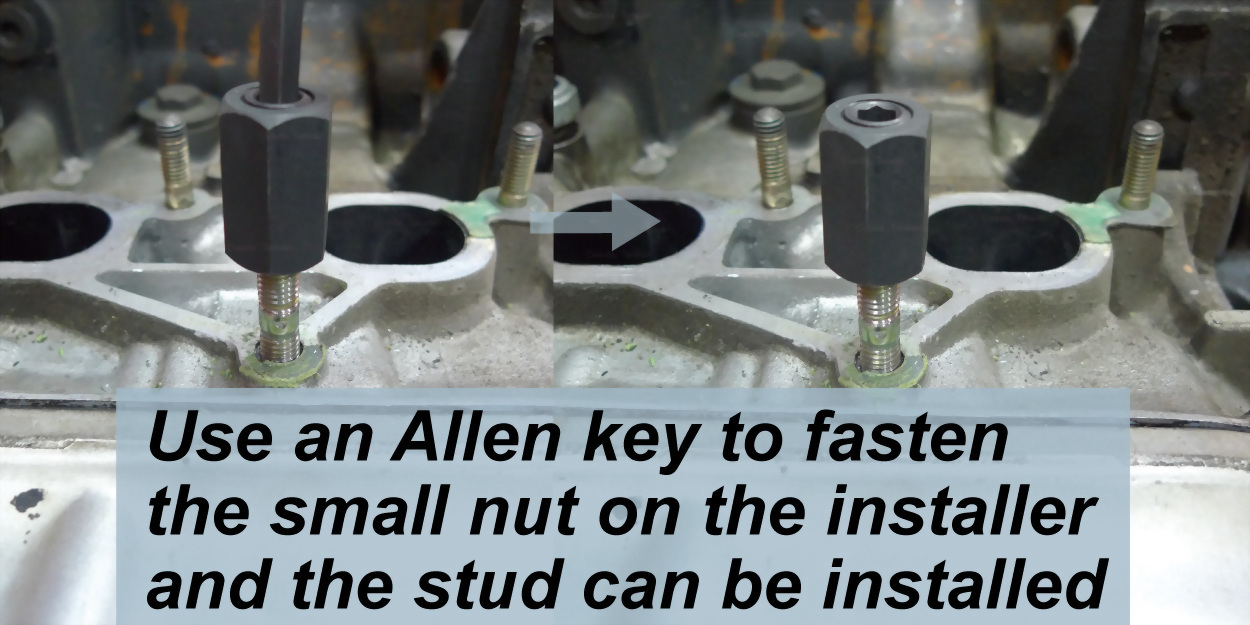

For installation, screw the stud to the place where it belongs, and screw the installer to the stud. When the installer is screwed to the end, take an allen key to fasten the inner hex on top of the installer and then you can remove the installer socket while keeping the stud still in place, and not damaging the threads on the stud.

| Package | Blow molded case (red) | |

| Packing | 20 sets in a master carton | |

| Weight per set | 515 g | 1.1 lbs |

| Net weight per carton | 10.3 kg | 22.7 lbs |

| Gross weight per carton | 11.3 kg | 24.9 lbs |

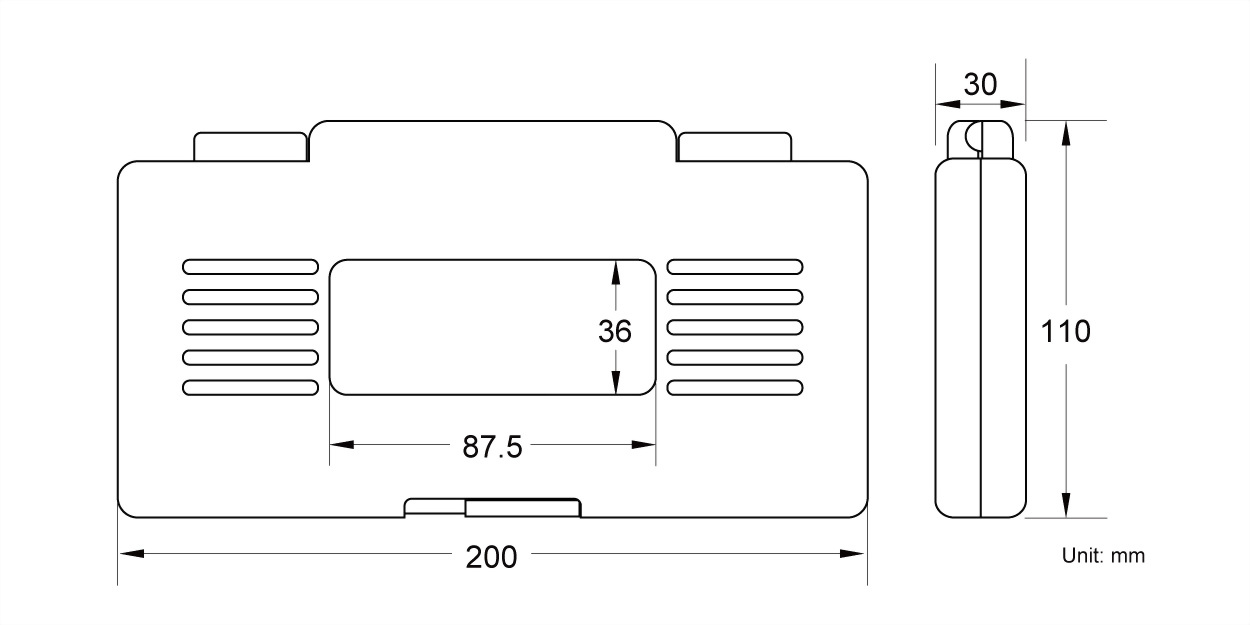

| Size per set | 20.0 × 11.0 × 3.0 cm | 7.9 × 4.3 × 1.2 in |

| Size per carton | 44.0 × 21.0 × 18.0 cm | 17.3 × 8.3 × 7.1 in |

| Volume per carton | 0.017 CBM | 0.6 CUFT |

| Case label size | 8.5 × 3.5 cm | 3.3 × 1.4 in |

| No. | Image | Cosda No. | Description | |||||

|---|---|---|---|---|---|---|---|---|

| 1 |  |

SD-1039-1 | M6 × P1.00 Installer | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 2 |  |

SD-1039-2 | M8 × P1.25 Installer | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 3 |  |

SD-1039-3 | M10 × P1.25 Installer | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 4 |  |

SD-1039-4 | M10 × P1.50 Installer | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 5 |  |

SD-1039-5 | M6 × P1.00 Remover | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 6 |  |

SD-1039-6 | M8 × P1.25 Remover | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 7 |  |

SD-1039-7 | M10 × P1.25 Remover | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 7 |  |

SD-1039-7 | M10 × P1.25 Remover | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 8 |  |

SD-1039-8 | M10 × P1.50 Remover | More |

||||

|

- Specifications

|

||||||||

| Suggested HS code |

82042000004 |

| MOQ with laser marking | 40 sets |

| MOQ without laser marking | 20 sets |

| Laser marking cost | + TWD 2 on each piece |