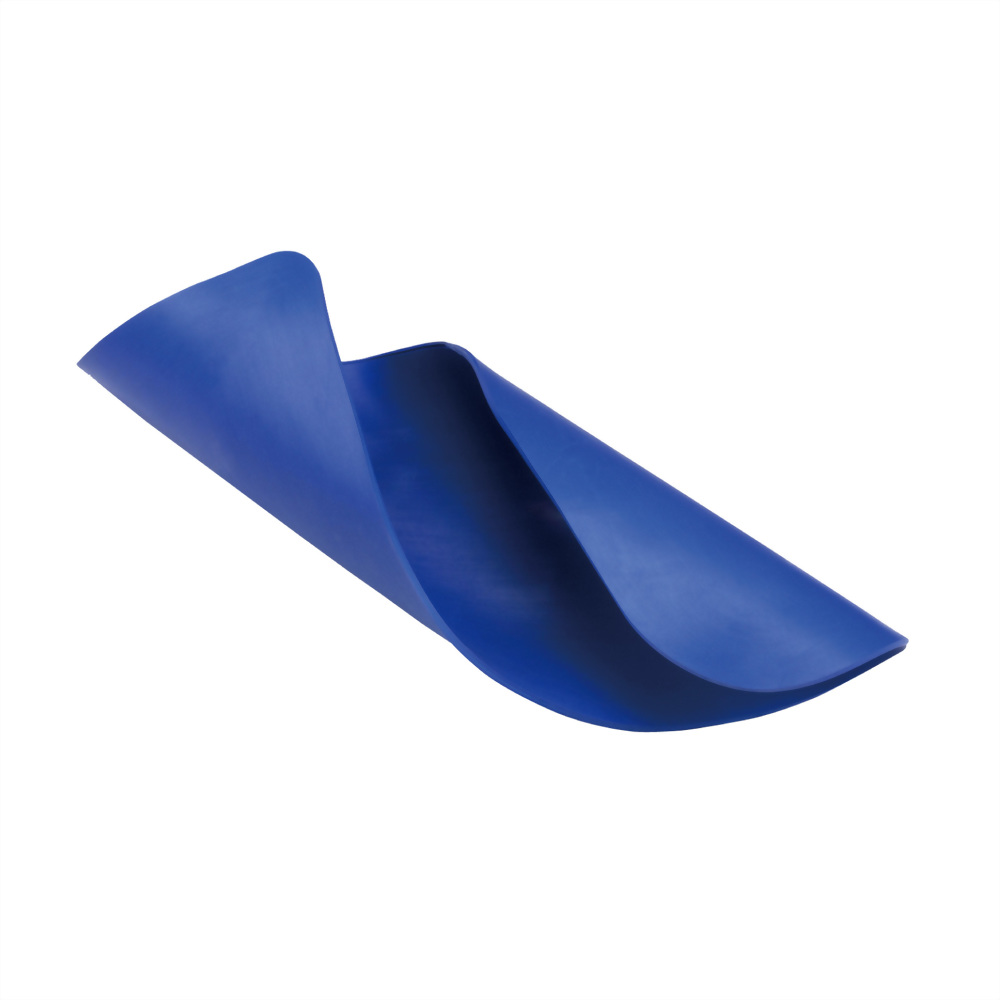

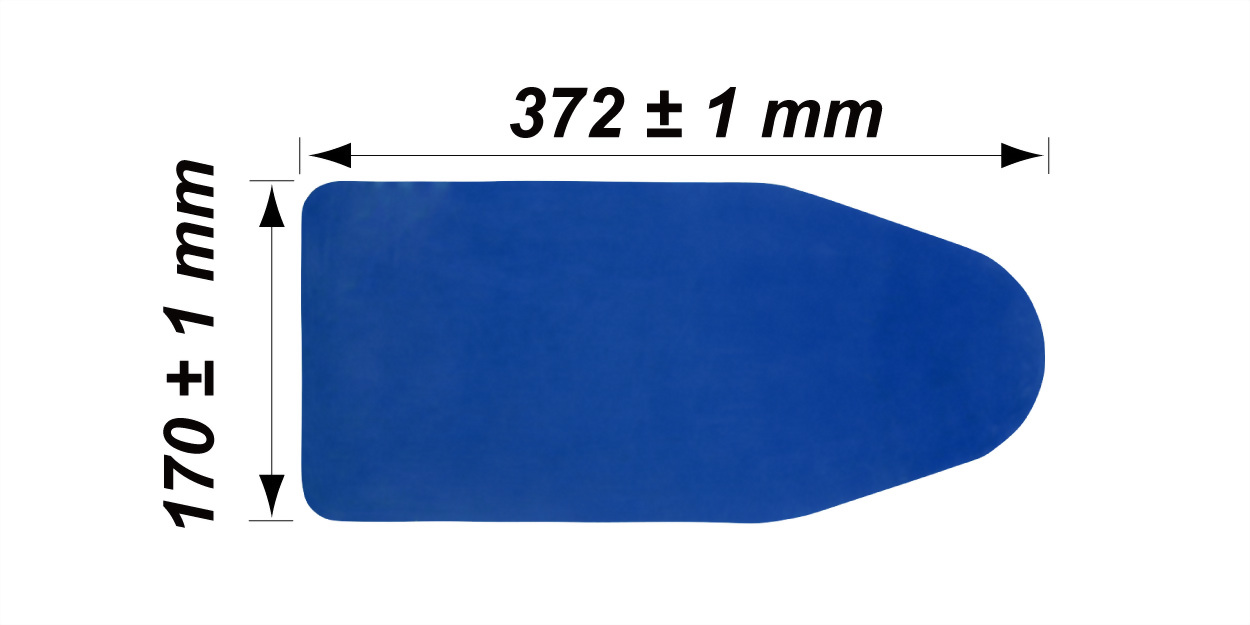

Flexible and Moldable Funnel (372 mm)

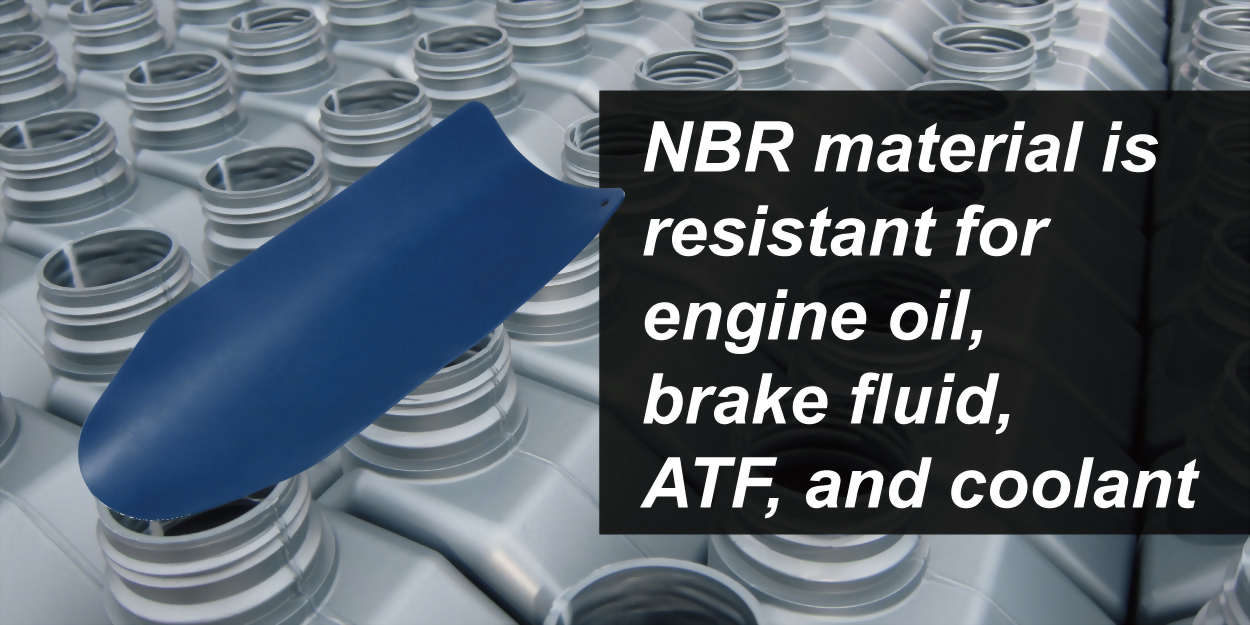

• Selected material for engine oil, brake fluid, ATF, and coolant

• Temperature range: -15˚C and 100˚C / 5˚F and 212˚F

• US patented product

KEY FEATURES

|

Feature |

Description |

Practical Benefit |

|

Flexible & Formable Design (372 mm) |

Bendable funnel sheet that can be shaped into a flow channel or traditional funnel |

Adapts to tight engine bays for cleaner draining and filling |

|

Drain Channel for Awkward Oil Filters |

Can be folded into a guided drain path under oil filters |

Reduces oil dripping onto subframes, control arms, and wiring |

|

Wipe-Clean, Non-Absorbent Surface |

Smooth surface resists sludge buildup and wipes clean easily |

Minimizes cross-contamination between old and new fluids |

|

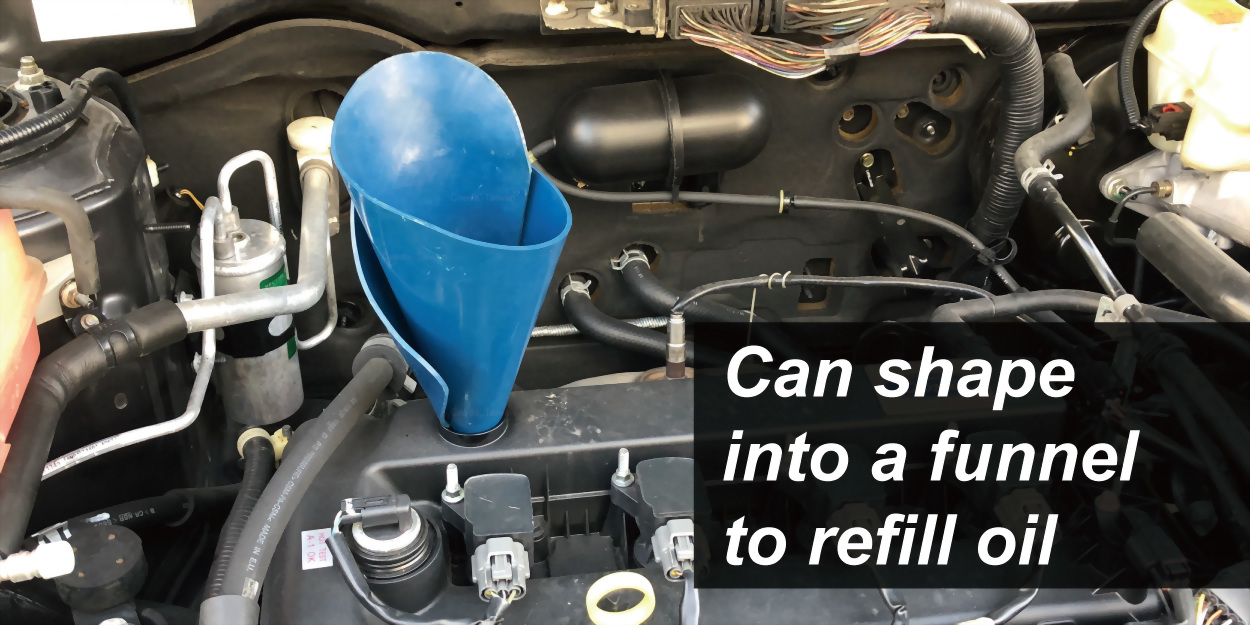

Deep-Neck Funnel Conversion |

Rolls into a deep funnel with pinchable narrow spout |

Enables precise, spill-free filling in recessed or angled fill ports |

|

Oil & Temperature Resistant |

Compatible with engine oil, brake fluid, ATF, and coolant (-15°C to 100°C) |

One funnel covers most workshop fluid tasks |

|

Aluminum Mesh Core + Nylon Layers |

Shape-retaining aluminum core with durable nylon outer layers |

Holds shape, won’t collapse, built for high-frequency professional use |

|

U.S. Patented, OEM-Ready Product |

U.S.-patented design by Taiwanese professional tool manufacturer |

Ideal for private label, branding, and long-term distribution |

1.Flexible, formable fluid-directing funnel (372 mm)

The 372 mm flexible funnel can be bent and folded to match real engine bay space, turning into either a “flow channel” or a traditional funnel shape. Whether draining or filling, it guides engine oil,brake fluid, ATF, and coolant more precisely and with less mess.

2.Engineered for awkward oil filter locations – fewer drips, less cleanup

For vehicles where the oil filter is hard to reach and prone to dripping everywhere, simply fold the funnel into a “drain channel” and place it under the filter. Residual oil is directed straight into the drain pan instead of onto subframes, control arms, or wiring looms, significantly reducing underbody wiping and cleanup time.

3.Smooth, wipe-clean surface reduces cross-contamination between old and new oil

After draining, just wipe the funnel with a rag or shop towel and it’s ready to be used as a filling funnel. The smooth surface resists sludge buildup and is easier to clean than traditional rigid funnels,helping to reduce the risk of old oil contaminating fresh oil and supporting professional fluid management standards.

4.Roll into a deep-neck funnel for precise, spill-free filling

Roll both sides inward and the sheet quickly becomes a deep-neck funnel. The tip can be pinched into a narrow spout to reach deeper fill necks and help prevent fluid from overflowing at the cap. This is especially useful on vehicles with recessed or awkwardly angled fill locations, greatly improving control and convenience during filling.

5.Oil- and temperature-resistant material for common workshop fluids

Made from a material compatible with engine oil, brake fluid, ATF, and coolant, with an operating temperature range of approximately -15°C to 100°C (5°F–212°F). It is well-suited for typical service bay conditions. For workshops, fleets, or serious DIY users, a single funnel can handle most draining and filling tasks.

6.Aluminum core with nylon outer layers – flexible, shapeable, and durable

The core uses a high-quality aluminum mesh structure wrapped in multiple nylon layers, providing:

- Flexibility for repeated bending and shaping

- Stable support that holds its shape without collapsing

- A smooth surface for fast, clean fluid flow and easy wiping

This construction is built to professional-tool standards and ideal for long-term, high-frequency use in service environments.

7.U.S. patented design, made by a Taiwanese professional tool manufacturer – ideal for branding

Model SD-5006 is a U.S.-patented product, designed and manufactured by Taiwanese automotive specialty tool maker Cosda, a long-term OEM and private-label partner for international tool brands. For distributors, retailers, or tool brands, this is more than just a funnel—it’s a professional product with R&D background,patent protection, and factory backing.

INDUSTRY BACKGROUND

1.

Why Modern Vehicle Maintenance Requires a Flexible & Moldable Funnel

Contemporary engine bays

have become increasingly compact due to aerodynamic optimization, the addition

of electronic systems, and stricter NVH requirements. Oil fill ports, drain

points, and filter housings are often surrounded by structural beams, wiring

harnesses, shields, or suspension components, frequently positioned at deep,

angled, or asymmetric locations. Traditional rigid funnels, with fixed angles,

cannot adapt to these confined spaces and often lead to spillage or obstructed

operations.

The Flexible & Moldable Funnel utilizes a shape-retaining aluminum mesh core that can be bent and formed according to the available space. This allows technicians to adjust the flow direction based on each vehicle layout. Rather than being a simple convenience, this design directly addresses the mechanical realities of modern engine bay construction and has become an essential replacement for fixed-angle funnels in today’s repair environment.

2.

Risks and Issues When No Flow-Control Tool Is Used

During oil draining or filter removal, residual oil often drips onto subframes,

control arms, wiring protectors, or chassis components if no guiding tool is

used. This increases cleanup time and may shorten the service life of rubber

materials.

When adding new oil in a confined space, improper angles easily cause oil to

spill outside the fill port—sometimes dripping onto the exhaust pipe and

producing smoke, leading to unnecessary troubleshooting. These issues occur

frequently in real workshop settings, and the Flexible & Moldable Funnel is

specifically designed to prevent such problems.

3.

Reducing Repair Risks and Liability Costs

Oil leakage and contamination of surrounding parts can result in customer

complaints, additional cleaning labor, or disputes over repair responsibility.

Fluids such as brake fluid and ATF have strong chemical properties; contact

with rubber wiring, insulation materials, or plastic components may cause

softening, brittleness, or long-term degradation.

By directing all fluids securely into the drain pan, the Flexible &

Moldable Funnel minimizes contamination at the source, reduces cleanup time,

and lowers the risk of post-service claims. Its stable moldable structure

allows more precise flow control, helping ensure compliance with warranty and

regulatory standards.

4.

Compliance With Safety and Environmental Regulations

Spilled

waste oil is considered an environmental violation risk in service centers, and

most regulations require proper collection of used fluids to prevent ground or

drainage contamination.

The Flexible & Moldable Funnel significantly reduces leakage probability

and ensures that all waste oil is directed into the collection container. Its

outer material is chemically resistant, easy to clean, and non-absorbent,

reducing fluid residue and cross-contamination. This aligns with modern

workshop safety and environmental management practices.

5. Evolution of Materials and Tool Design

The funnel as a tool has existed for centuries, but its rigid, fixed-angle

structure remained largely unchanged. As engine bays became more confined,

technicians’ need for an adjustable flow-direction tool became evident.The Flexible & Moldable Funnel incorporates a layered structure using an

aluminum mesh core for shape retention and a nylon outer surface for chemical

resistance and smooth flow. This design introduces true moldability to the

funnel category for the first time.It represents not just a variation of the traditional funnel but a

technological evolution driven by modern repair challenges. The design has also

been granted a U.S. patent and is increasingly adopted as a standard tool in

today’s automotive service facilities.

SOLUTION

Solution 1 – Logo-Printed Flexible Funnel for Private Label Programs

Turn this flexible funnel into a logo-printed flexible funnel for automotive tool brands, private label programs, and distributors.

Key Benefits:

·Your logo can be printed directly on the funnel surface, creating a private label flexible funnel suitable for repeated daily use in workshop environments.

· MOQ: 120 sets One-time tooling cost: USD 80

This solution is suitable for OEM automotive accessory programs and aftermarket tool brands.

Solution 2 – Color-Customized Funnel for Brand Identity & Product Lines

Use color customization to turn this flexible funnel into a brand-aligned automotive funnel for professional and retail markets.

Key Benefits:

- Funnel color can be customized (e.g. black) to match brand identity or product line positioning for automotive tool brands.

- Color-based differentiation supports OEM programs, private label tool ranges, and retail product segmentation.

- Other colors can be evaluated upon request, offering flexibility for long-term product planning.

Solution 3 – Card Package & Barcode Funnel for Retail and E-commerce

Build a retail-ready flexible funnel for e-commerce sellers, retail chains, and distributors.

Key Benefits:

- Customized card packaging allows brands to launch a retail flexible funnel product quickly with their own artwork.

- UPC / EAN barcode labels support Amazon, online platforms, and retail inventory systems.

- This solution lowers packaging entry barriers for private label and distributor programs.

Solution 4 – Multi-Market Packaging for Global Distribution

Support multi-market sales and global distribution with flexible packaging options.

Key Benefits:

- Barcode and label customization allows the same flexible funnel model to be used across different markets.

- Ideal for distributors and OEM customers managing multiple regions.

- Keeps product structure simple while supporting market-specific requirements.

Solution 5 – Bundle-Ready Funnel for Fluid Handling Kits

Position SD-5006 as part of a complete fluid handling kit for professional service environments.

Key Benefits:

- The flexible funnel can be bundled with oil containers, drums, or refill tools to create workshop service kits.

- Suitable for garage chains, fleet service providers, and mobile service units.

- Helps suppliers move from selling a single tool to offering a complete fluid handling solution.

Q&A

Q1: What fluids is it compatible with?

A: The selected material is compatible with typical automotive fluids

such as engine oil, brake fluid, ATF, and coolant. For unusual chemicals (e.g.,

solvents or fuels), please verify compatibility first.

Q2: What is the operating temperature range?

A: -15°C to 100°C (5°F to 212°F), suitable for typical service

conditions.

Q3: What is the length? Is there a longer version

available?

A: This model is 372 mm

(SD-5006). For extra reach suitable for trucks and heavy-duty vehicles,

choose SD-5006D (556 mm).

Q4: Can the same funnel be used for both draining

and refilling?

A: Yes. After draining, wipe

it clean with a shop towel and reshape it into a deep-neck funnel for refilling

to minimize cross-contamination. For higher cleanliness requirements, consider

separating tools by fluid type.

Q5: How do I clean it? Do I need soaking or special

cleaners?

A: The smooth, non-absorbent surface helps resist sludge buildup.

Cleaning is typically as simple as wiping it dry—no soaking or special process

required.

| Package | Sliding card + blisters | |

| Packing | 10 sets in an inner carton, 40 in a master carton | |

| Weight per set | 265 g | 0.6 lbs |

| Net weight per carton | 10.5 kg | 23.2 lbs |

| Gross weight per carton | 11.5 kg | 25.3 lbs |

| Size per set | 22.5 × 20.5 × 4.0 cm | 8.9 × 8.0 × 1.6 inch |

| Size per carton | 50.3 × 32.4 × 46.0 cm | 19.8 × 12.8 × 18.1 inch |

| Volume per carton | 0.075 CBM | 2.6 CUFT |

| Suggested HS code |

39269090908 |

| MOQ without logo printing | 40 sets |

| Logo printing cost | + TWD 8 with an MOQ of 120 sets |

| Logo printing tooling cost | + TWD 2,500 |

|

Not for sale in |

China, Japan, and USA |