Commercial Vehicle Use Cooling System Vacuum Coolant Refill and Pressure Leak Tester Kit

causing engine overheat or related issues

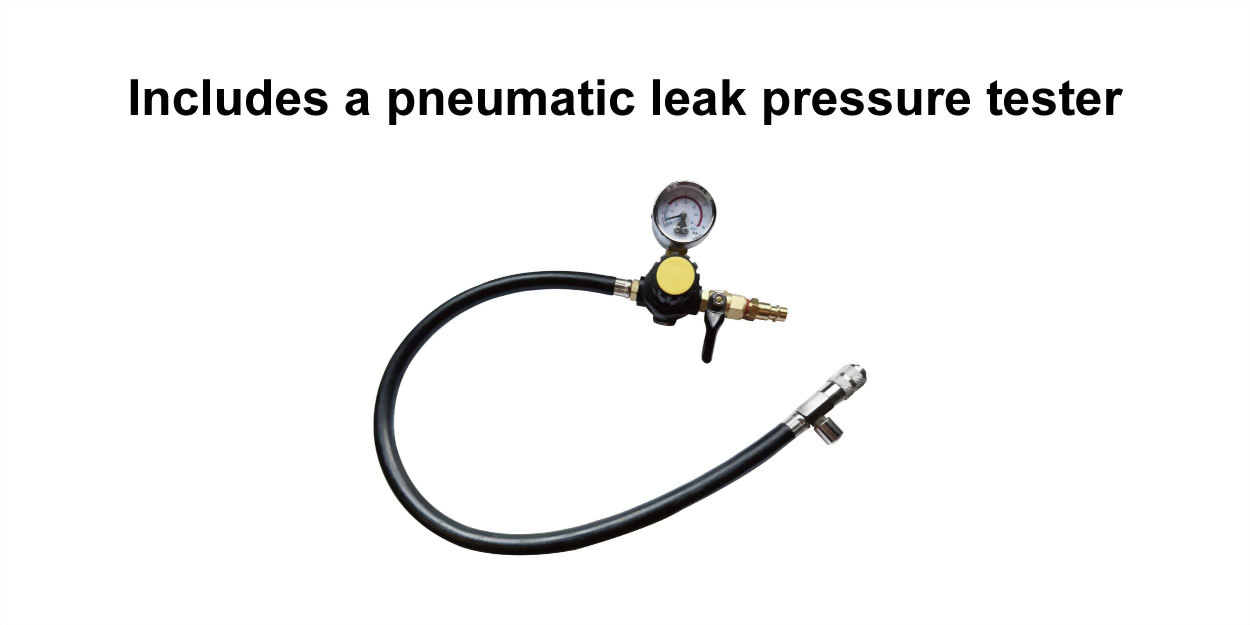

• Provided with an air pressure device for fast pressurizing on large capacity cooling systems

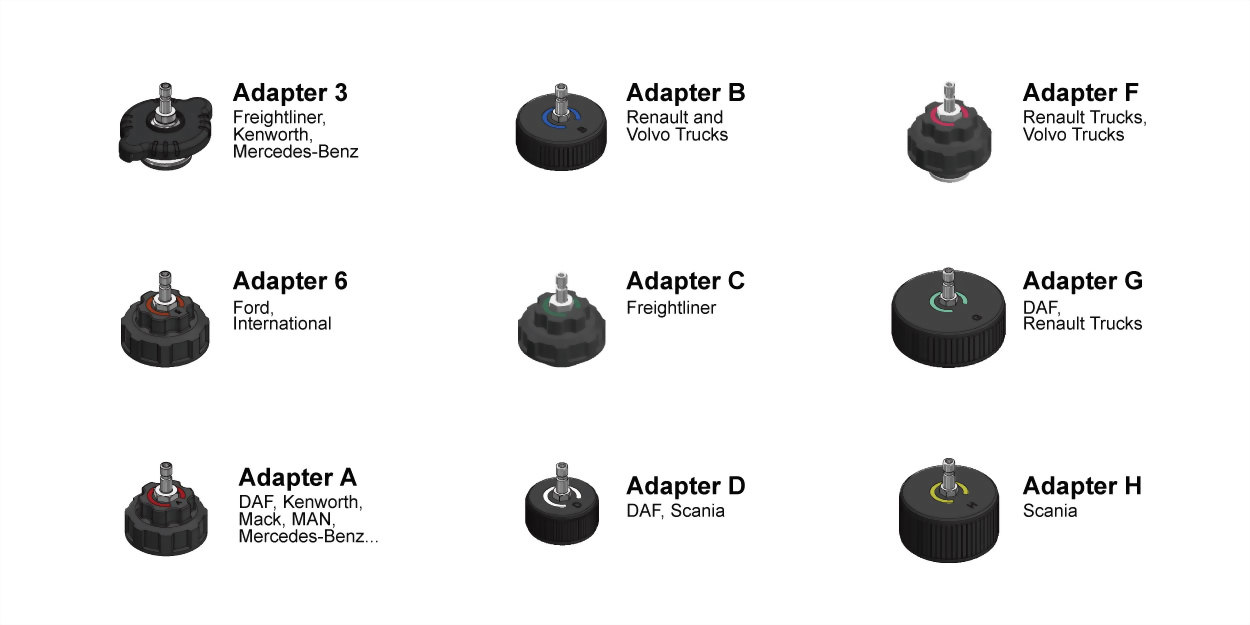

• Includes 9 adapters compatible with heavy-duty vehicles and commercial trucks, including DAF, Ford Trucks, Freightliner, International, Kenworth, Mack, MAN, Mercedes-Benz, Peterbilt, Renault Trucks, Scania, and Volvo Trucks

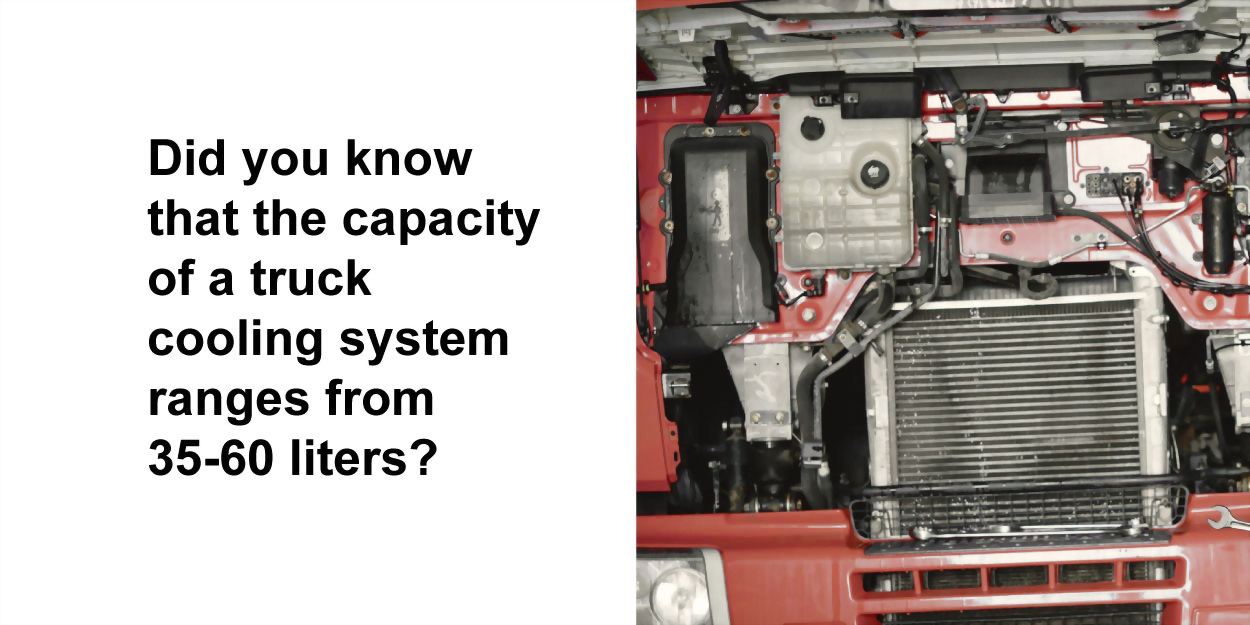

Commercial vehicle cooling-system capacity varies a lot with engine size, chassis layout, auxiliary coolers (A/C oil cooler, transmission oil cooler and etc), and the exact model-year and engine codes. The table below shows a quick reference on the capacity of the truck cooling systems

Make

Model

Capacity (liter)

Capacity (US gallon)

Freightliner

Cascadia

75–95

20-25

International

DuraStar (4300 / medium-duty)

20-30

5-8

Iveco

S-Way (heavy-duty)

44-64

11.6-16.9

Kenworth

W900

26-38

7-10

Mack

Pinnacle (CXU/MP8, etc.)

36-50

9.5-13.2

MAN

TGL

21.5

5.7

Mercedes-Benz

Atego

23

6.1

Renault Trucks

Midlum

22-25

5.8-6.6

Scania

P / G / R / T series

44

11.6

For checking if there are leaks on the truck cooling system, you'd want to check the coolant level first by seeing if the coolant fills up between the MIN - MAX lines on the recovery tank or surge tank. Oh, also never check the leaks when the cooling system is still hot. Wait for it to cool down, or it can be dangerous to open the coolant cap while the cooling system is still hot and pressurized.

Choose an easy access point on the surge tank. Usually there are two coolant caps on the surge tank on commercial vehicles, and they are designed that way not just for fun - they do serve different purposes: one cap is the Pressure Cap (main radiator or expansion cap). This cap is very similar to automotive pressure caps - it has a pressure value (commonly 1.0-1.5 bar) indicated on the surface of the cap, and it releases excess pressure to a secondary reservoir or overflow pipe if needed. This cap is critical for maintaining the proper boiling point of the coolant. The second cap is the service or inspection cap (non-pressurized). This is typically a smaller cap and does not seal the pressurized part of the system, and it's used for visual inspection or adding coolant safely when the engine is cold. Sometimes it acts as an access point for bleeding air from the cooling system.

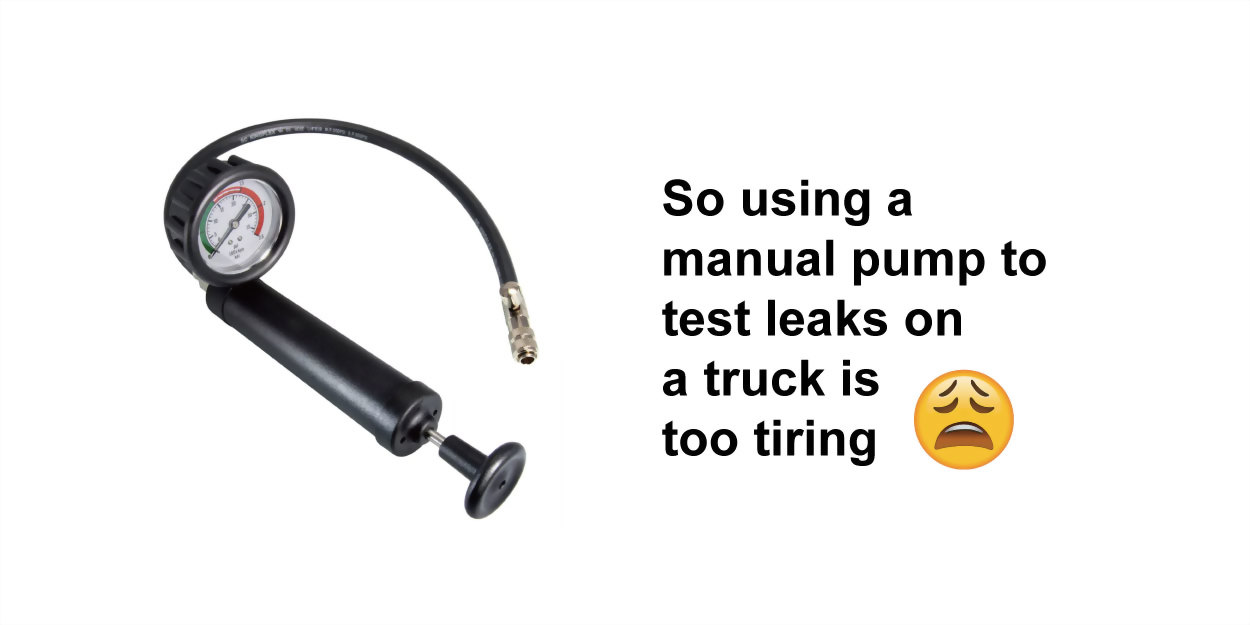

Coming back to the pressure leak test. Cosda designed this tool set using a pneumatic tool to pressurize the system quickly. Although we are going to pressurize the system while the coolant is full, the remaining area inside the surge tank is substantially larger than automotive expansion tanks, and pumping pressure into the truck cooling system manually is very tiring. Cosda is constantly looking for solutions that can help mechanics servicing the cars and trucks in a more efficient way.

Just like automotive cooling system maintenance processes, there are two ways of changing coolant on commercial vehicles: the gravity fill and the vacuum-type coolant refill. Using the gravity fill method is very common and it doesn't require any specialty tools. You'd only need buckets with pre-mixed coolant and the clean, wide open funnel, but this method needs a time-consuming air bleeding, or de-aerating if you want to sound more sophisticated. The regular air bleeding on commercial trucks takes slightly longer than automotives, about 45 minutes because of (1) larger capacities in the truck cooling system and (2) longer coolant lines as well as multiple circuits such as EGR cooler and oil cooler.

Failure to perform air bleeding creates air pockets in various places in the truck cooling system and lead to overheating, poor cab heater performance, air locks at the water pump, and possibly fault codes on electronically monitored systems (EGR temp, coolant temp spikes). Therefore, using the vacuum-type coolant refill tool not only reduces coolant change time, but also reduces much anxiety on above mentioned problems. Once everything is well prepared, that is, adequate volume of pre-mixed coolant and an air compressor, using vacuum-type coolant refiller reduce coolant changing time down to less than 10 minutes.

This coolant refill tool designed by Cosda is very compact. First you want to find a suitable adapter, shown below, to connect to the surge tank, after draining the old coolant. Connect the refill tool to the adapter, and attach air compressor to the refill tool. Slide the tab to the "Vacuum" side and the vacuum will gradually be created in the cooling system. On the other end, connect the hose provided and make sure the filter end is constantly submerged under the surface level of the new and pre-mixed coolant. Once the gauge shows about -0.8 bar, slide the tab to "Fill" side, and the new coolant will be introduced to the cooling system instantly. Finally just wait for the gauge to read 0 and check the coolant level. Top it up manually if there's still a bit remaining level left.

Cosda has been investing in much time and resources on developing this truck cooling system service tool set, specifically on researching the coolant cap adapter applications. There are some truck oriented cooling system service tool sets on the market, but they are either outdated (been existing since the past 30 years) or market-limited (only for trucks in the US). So Cosda is trying to provide a solution to provide commercial vehicle cooling system cap adapters for the most recent car makes and models and to cover both American and European truck manufacturers and different models. The table below shows an example of the applications from the 9 adapters included in this kit. Of course more applications are possible, and feel free to contact us for more details.

Make

Model

Years

Adapters

DAF

CF 65, 75, 85

2001-2013

D & G

DAF

CF 12.9L

2013-2024

A & D

DAF

XG 10.8L, 12.9L

2021-2025

D

Ford

F-750 5.9L, 6.7L, 7.2L

2004-2015

6

Freightliner

Century Class 10.3L, 14.6L

2004-2010

C

Freightliner

M2 106, 112

2008-2019

C

International

LoneStar 14.9L, 15.2L

2010-2021

6

International

HX Series 9.0L, 12.4L

2020-2022

6

Iveco

S-Way 11.1L, 12.9L

2019-2024

D

Iveco

Trakker 7.8L, 12.9L

2004-2021

A

Kenworth

T660 11.9L, 14.9L

2008-2019

3

Kenworth

W900 8.8L, 10.8L, 15.8L

2008-2022

A

Mack

Athem MP7, MP8

2018-2025

A

MAN

TGL 4.6L, 6.9L

2005-2022

A

MAN

TGX 10.5L, 12.4L, 16.2L

2007-2021

A

Mercedes-Benz

Actros MP4, MP5

2011-2025

A

Mercedes-Benz

Antos

2012-2025

A

Peterbilt

365 11.9L, 12.9L

2008-2022

A

Renault Trucks

D-Series 7.7L

2013-2025

A & B

Renault Trucks

K-Series

2013-2025

F

Renault Trucks

Magnum

1990-2013

G

Scania

P, G, R, T - series

2003-2017

D & H

Volvo Trucks

FE 7.1L, 8.8L

2012-2025

A & B

Volvo Trucks

FMX 420, 460, 500

2012-2020

F

Volvo Trucks

VN 300, 610, 770

2000-2024

A

Q&A

Q1. Which commercial vehicle brands are compatible with this vacuum refill tool set?

A: The kit includes 9 adapters that fit a wide range of American and European trucks, such as DAF, Iveco, Scania, Volvo, Mercedes-Benz, Freightliner, Kenworth, and International models.

Q2. When should I avoid opening the coolant cap?

A: Never open the coolant cap when the engine or cooling system is still hot. High temperature and pressure may cause steam to spray out and lead to injury or system damage.

Q3. What is the difference between gravity fill and vacuum-type coolant refill?

A: Gravity filling requires long air bleeding (around 45 minutes) and may trap air inside the system. A vacuum refill removes air first and fills the coolant in under 10 minutes, resulting in a more efficient and safer process.

Q4. Can this tool set be used for cooling system leak testing?

A: Yes. The pneumatic pressure tool in the kit can pressurize the cooling system (when cold) to check for leaks.

Q5. What should I prepare before using the vacuum refill tool?

A: Prepare pre-mixed coolant, an air compressor, the correct adapter, and ensure the suction filter remains fully submerged in the coolant during operation.

Package: Black blow molded case

Packing: 4 sets in a master carton

Weight per set: 3.72 kg

Net weight per carton: 15 kg

Gross weight per carton: 16 kg

Size per set: 46 × 32 × 10.5 cm

Size per carton: 48 × 46 × 24 cm

Case label size: 25.5 × 10 cm

Volume per carton: 1.8 CUFT

| No. | Image | Cosda No. | Description | |||||

|---|---|---|---|---|---|---|---|---|

| 1 |  |

SD-1015B-1 | Commercial Vehicle Use Vacuum-type Coolant Refill | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 2 |  |

SD-1015B-2 | Commercial Vehicle Use Pressure Leak Tester | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 3 |  |

SD-1015B-3 | Coolant Hose with a Filter at the End | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 4 |  |

SD-1291-3 | No. 3 Test Cap for SD-1291 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 5 |  |

SD-1291-6 | No. 6 Test Cap for SD-1291 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 6 |  |

SD-1291-A | No. A Test Cap for SD-1291 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 7 |  |

SD-1015B-B | Commercial Vehicle Use Cooling System Adapter for Renault and Volvo Trucks | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 8 |  |

SD-1291-C | No. C Test Cap for SD-1291 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 9 |  |

SD-1015-8A | Commercial Vehicle Use Cooling System Adapter for DAF and Scania Marked as D | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 10 |  |

SD-1291-F | No. F Test Cap for SD-1291 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 11 |  |

SD-1015_G | Commercial Vehicle Use Cooling System Adapter for DAF and Renault Trucks | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 12 |  |

SD-1015_H | Commercial Vehicle Use Cooling System Adapter for Scania | More |

||||

|

- Specifications

|

||||||||

Suggested HS code: 90262092007

MOQ with logo laser marking: 40 sets

MOQ without logo laser marking: 10 sets

Logo laser marking cost: + TWD 4 each marking

Not for sale in: China