Coolant Refill Kit for EVs

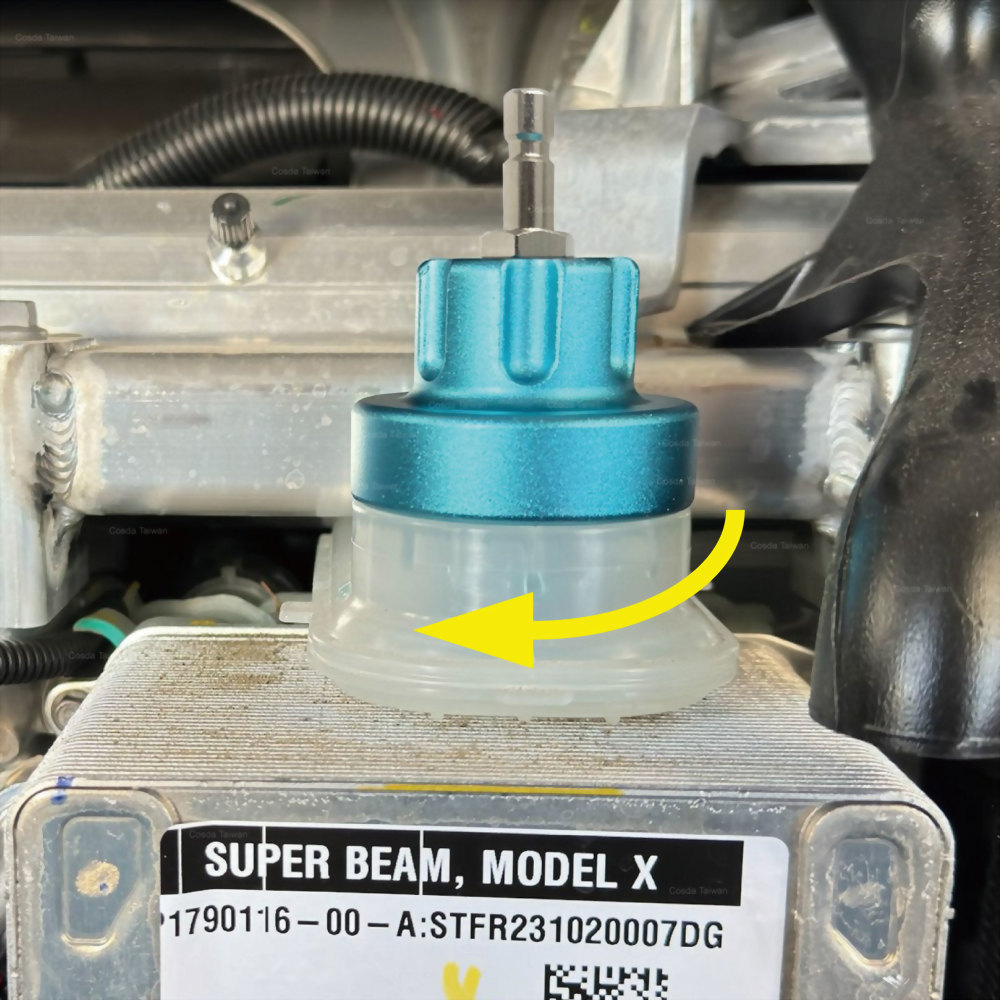

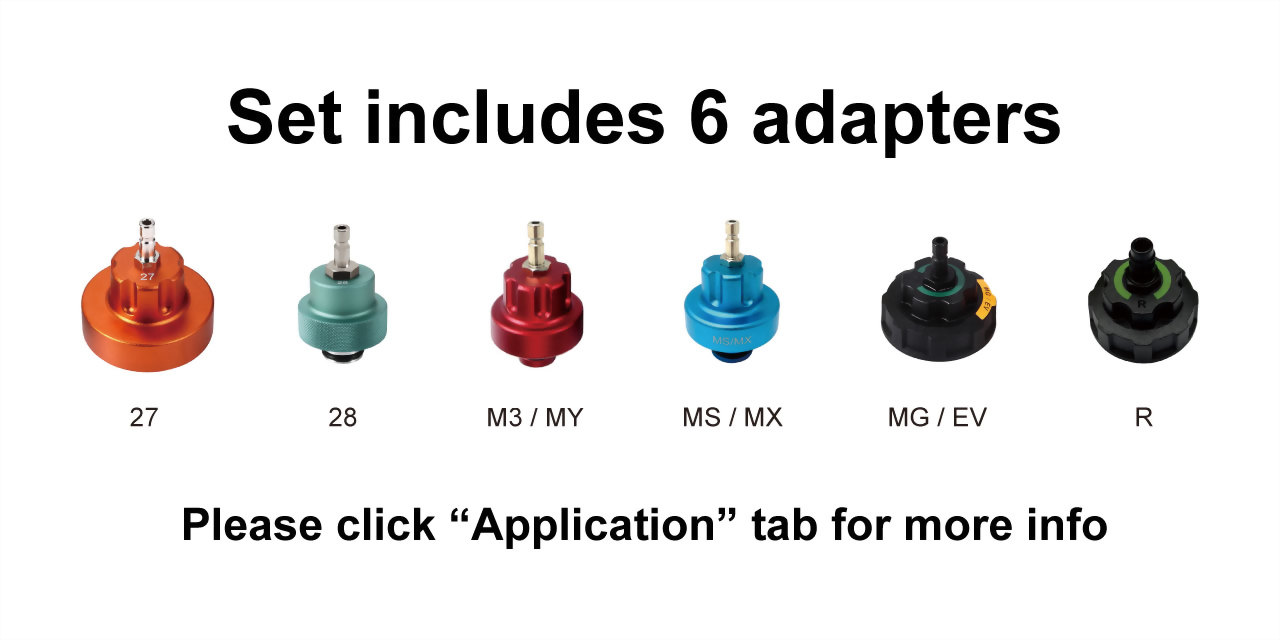

• Provided with adapters for various battery electric, plug-in hybrid, and conventional internal combustion engine car models

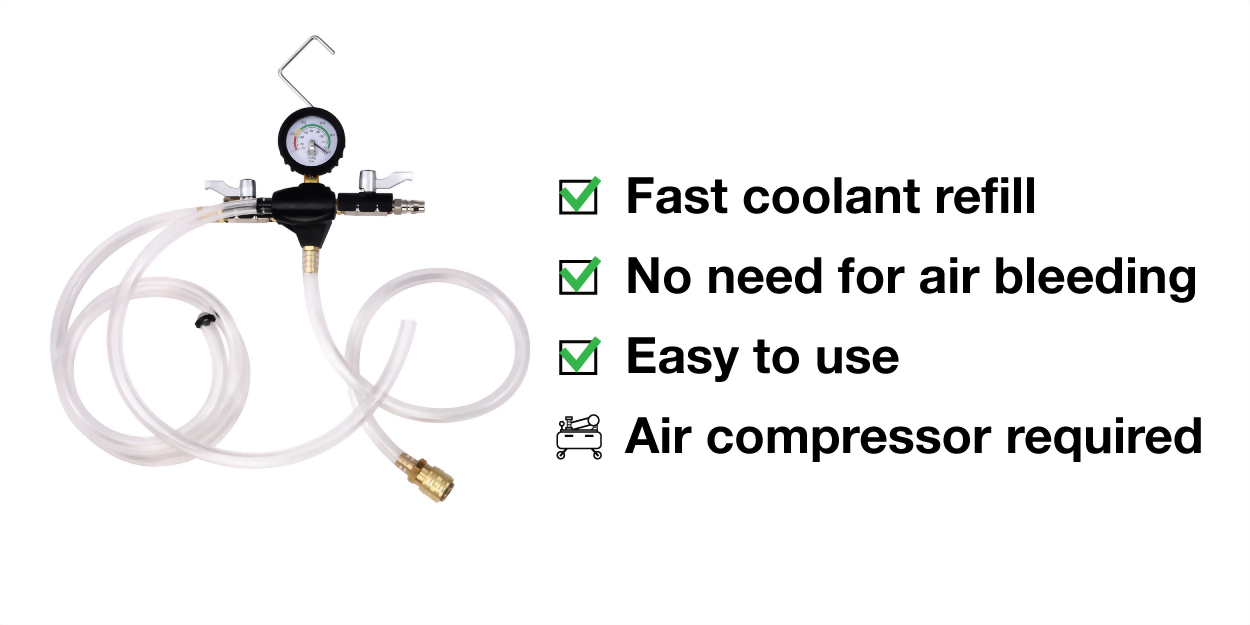

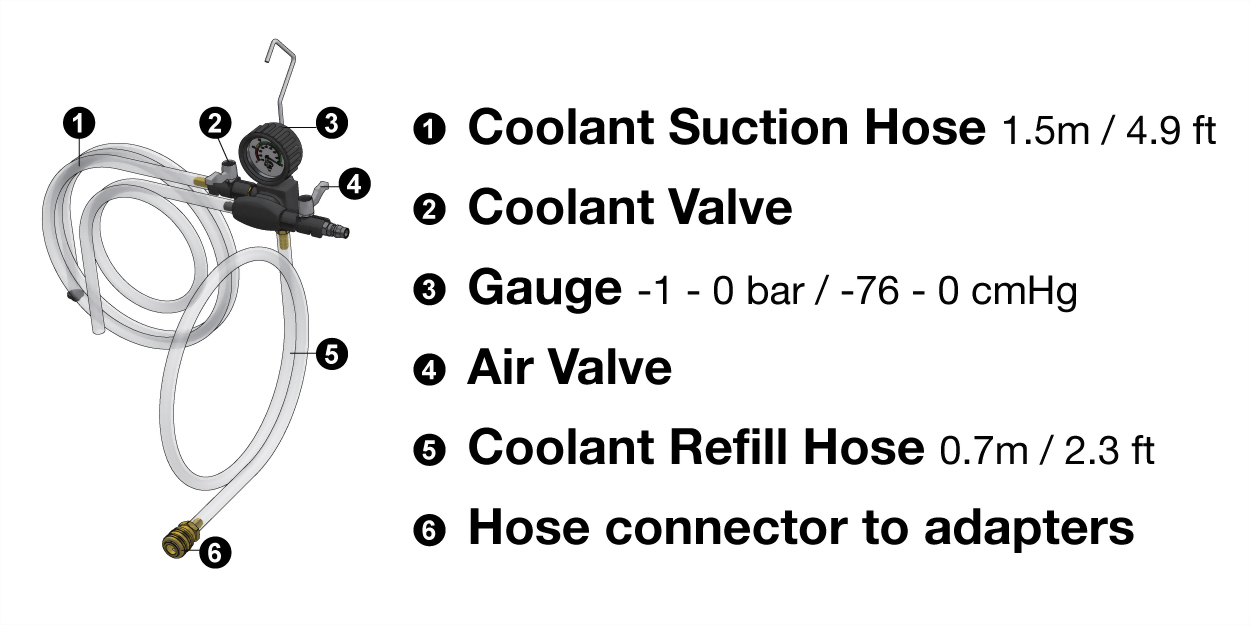

• Tool is designed with only two valves - easy to use, intuitive design

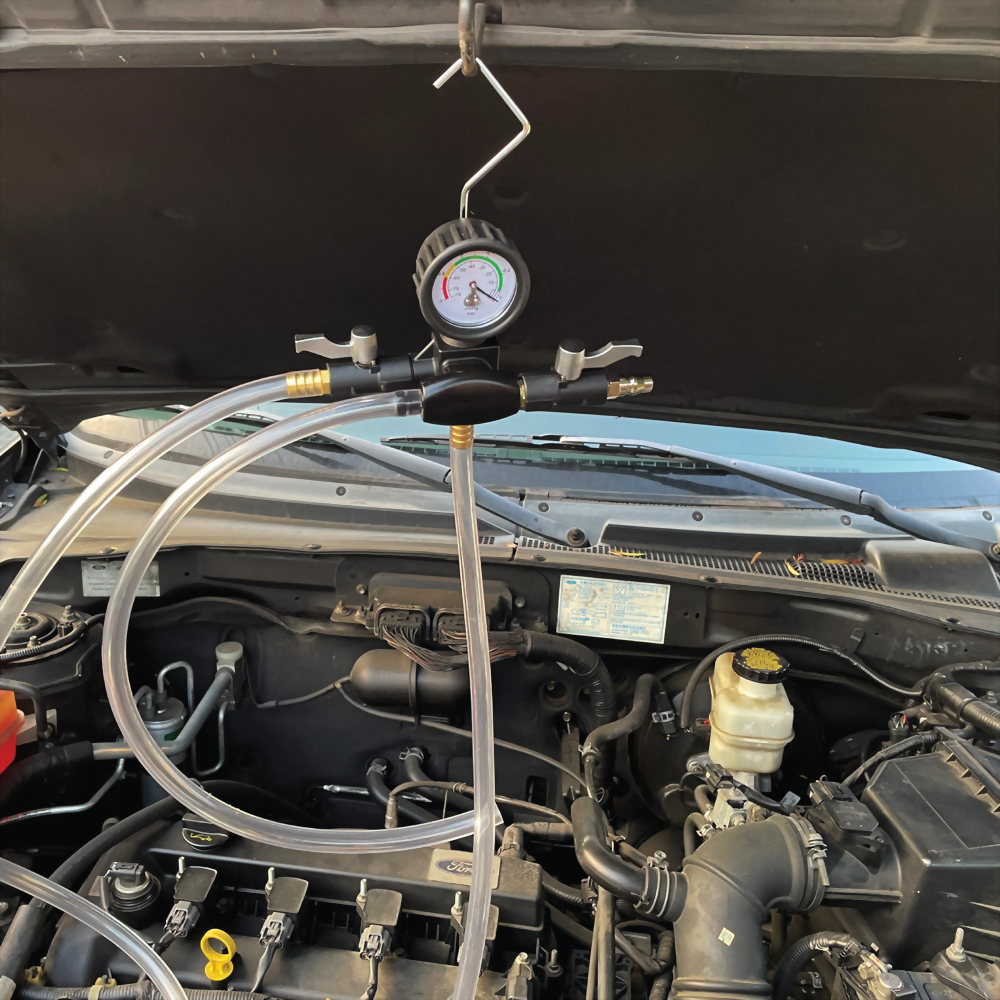

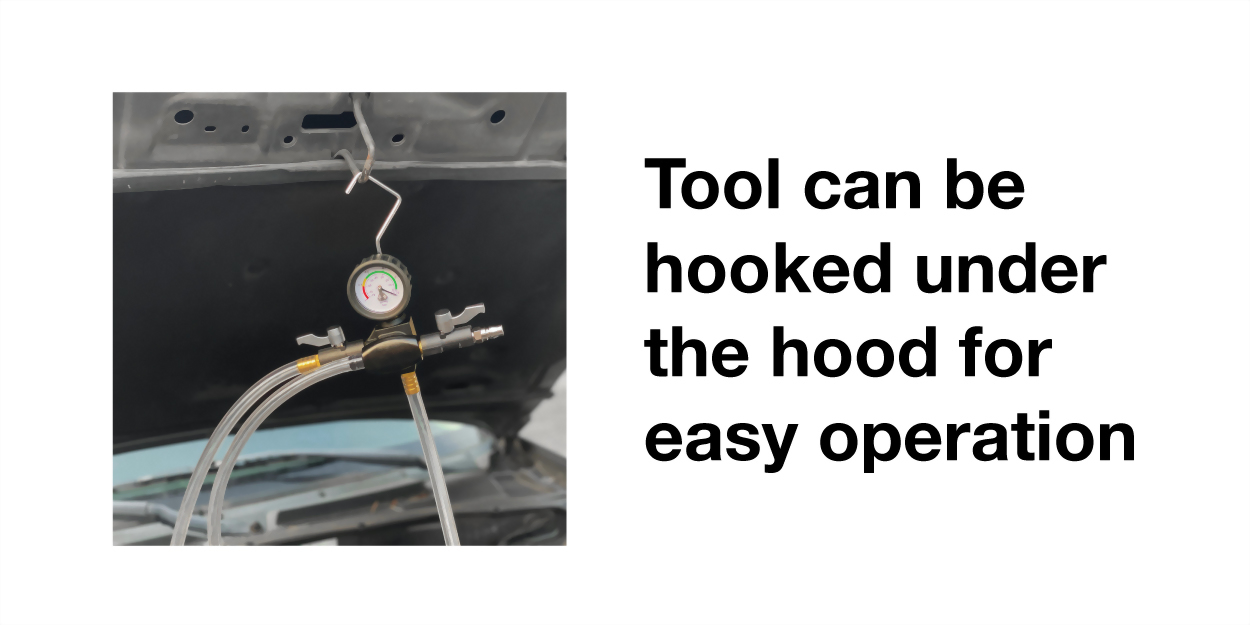

• Tool with a hook that can be hung under the hood

• Tool needs to work with an air compressor to create a vacuum in the cooling system

Are there any differences for cooling system coolant change on electric vehicles and internal combustion chamber engines?

Are there any differences for cooling system coolant change on electric vehicles and internal combustion chamber engines?

Yes, there are several key differences between changing the coolant in electric vehicles (EVs) and internal combustion engine (ICE) vehicles, primarily due to the distinct design and function of their cooling systems. Here’s an overview of the main differences:

1. Purpose of the Cooling System:

- Electric Vehicles (EVs):

- Battery Cooling: The primary purpose of the cooling system in EVs is to regulate the temperature of the battery pack. Maintaining the battery within an optimal temperature range is crucial for performance, safety, and longevity.

- Power Electronics Cooling: The cooling system also manages the temperature of power electronics (like the inverter) and the electric motor.

- Cabin Heating/Cooling Integration: In some EVs, the cooling system is integrated with the cabin heating and cooling system, particularly in vehicles that use a heat pump.

- Internal Combustion Engine (ICE) Vehicles:

- Engine Cooling: The main purpose is to remove excess heat generated by the internal combustion process in the engine.

- Transmission Cooling: In some vehicles, the cooling system also manages the temperature of the transmission fluid.

- Cabin Heating: The cooling system is often linked to the vehicle's heating system, which uses engine heat to warm the cabin.

2. Coolant Type:

- EVs:

- Specialized Coolants: EVs often require specialized coolants that are formulated to be compatible with the materials in the battery, electric motor, and power electronics. These coolants typically have specific thermal properties, low conductivity, and are designed to work within the narrow temperature ranges required by EV components.

- Longer Lifespan: EV coolants are often designed to last longer and may not need to be changed as frequently as in ICE vehicles.

- ICE Vehicles:

- Ethylene Glycol-Based Coolants: Most ICE vehicles use ethylene glycol-based coolants, which are effective in preventing freezing and boiling, and are designed to protect the engine and radiator from corrosion.

- Variety of Coolants: There’s a wider variety of coolant types and colors used in ICE vehicles, depending on the manufacturer and the specific engine requirements.

3. Cooling System Complexity:

- EVs:

- Multiple Cooling Circuits: EVs often have multiple, separate cooling circuits for different components (e.g., battery, power electronics, motor). Some systems may include active thermal management that involves heating and cooling to keep components within an optimal range.

- Electric Pumps and Sensors: The cooling system in EVs typically relies on electric pumps and a network of sensors to monitor and control the temperature in various parts of the system.

- ICE Vehicles:

- Single Cooling Circuit: Most ICE vehicles have a single, relatively simple cooling circuit designed to manage engine temperature, with a mechanical water pump driven by the engine.

- Less Sensor Integration: While modern ICE vehicles may have some sensors to monitor coolant temperature and levels, the system is generally less complex than in EVs.

4. Coolant Change Procedure:

- EVs:

- Advanced Tools Required: Changing the coolant in an EV often requires advanced diagnostic tools, especially if the vehicle has an integrated thermal management system that needs to be reset or recalibrated after the coolant change.

- System Bleeding: EV cooling systems may require careful bleeding to remove air pockets, sometimes using automated bleeding processes controlled by the vehicle’s software.

- Specialty tool offered by Cosda: Cosda provides bleeding-free cooling system coolant change tools that use vacuum to refill coolant in a fast manner, and the most important of all, no lengthy air bleeding process is required.

- Safety Precautions: Extra care is needed to avoid damaging the high-voltage components or causing a short circuit, as the cooling system in EVs may be in close proximity to sensitive electrical parts.

- ICE Vehicles:

- More Familiar Process: The process of draining and refilling coolant in an ICE vehicle is generally more straightforward and familiar to most mechanics.

- Manual Bleeding: The system usually requires manual bleeding to remove air pockets, but this is a standard procedure.

- Lower Risk: There’s less risk of interfering with electrical systems compared to EVs.

5. Maintenance Intervals:

- EVs:

- Less Frequent Changes: Coolant in EVs may need to be changed less frequently due to the lower operating temperatures and less aggressive thermal cycling compared to ICE engines.

- ICE Vehicles:

- Regular Maintenance: Coolant changes are typically required at regular intervals (every few years or based on mileage) due to the higher operating temperatures and the need to protect the engine from corrosion.

Summary:

The primary differences in coolant changes between EVs and ICE vehicles stem from the different roles the cooling systems play in each type of vehicle, the complexity of the systems, and the types of coolant used. EVs have more complex cooling systems with specialized coolants and procedures, often requiring specialized tools and knowledge. In contrast, ICE vehicles have simpler, more familiar cooling systems focused on engine temperature management.

| Package | Blow molded case (red) + EVA foam | |

| Packing | 2 sets in a master carton | |

| Weight per set | 4.55 kg | 10 lbs |

| Net weight per carton | 9.1 kg | 20 lbs |

| Gross weight per carton | 10.1 kg | 22.2 lbs |

| Size per set | 52.8 × 43.4 × 12.6 cm | 20.8 × 17.1 × 5.0 inch |

| Size per carton | 53.5 × 45.5 × 26.0 cm | 21.1 × 17.9 × 10.2 inch |

| Volume per carton | 0.63 CBM | 2.2 CUFT |

| Case label size | 16.9 × 6.9 cm | 6.7 × 2.7 inch |

| No. | Image | Cosda No. | Description | |||||

|---|---|---|---|---|---|---|---|---|

| 1 |  |

SD-1291-BODY | Vacuum Type Coolant Refill Tool | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 2 |  |

SD-1291-26 | No. 26 Cooling System Test Cap | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 3 |  |

SD-1291-30 | No. 30 Cooling System Test Cap | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 4 |  |

SD-1018-27 | No. 27 Test Cap for MG ZS HS MG4 | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 5 |  |

SD-1291S-MG-01 | Test Cap for MG Battery and EDS Coolant Expansion Tanks | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 6 |  |

SD-1018-28 | No. 28 Test Cap for Fiat 500e | More |

||||

|

- Specifications

|

||||||||

|

|

||||||||

| 7 |  |

SD-1291-R | No. R Test Cap for SD-1291 | More |

||||

|

- Specifications

|

||||||||

| Suggested HS code |

90262092007 |

| MOQ with laser marking | 8 sets |

| MOQ without laser marking | 4 sets |

| Laser marking cost | + TWD 3 on non-nylon based adapters |

|

Logo printing cost |

+ TWD 3 on nylon refill tool with TWD 2,000 printing tooling cost |

| Logo printing MOQ | 100 sets |