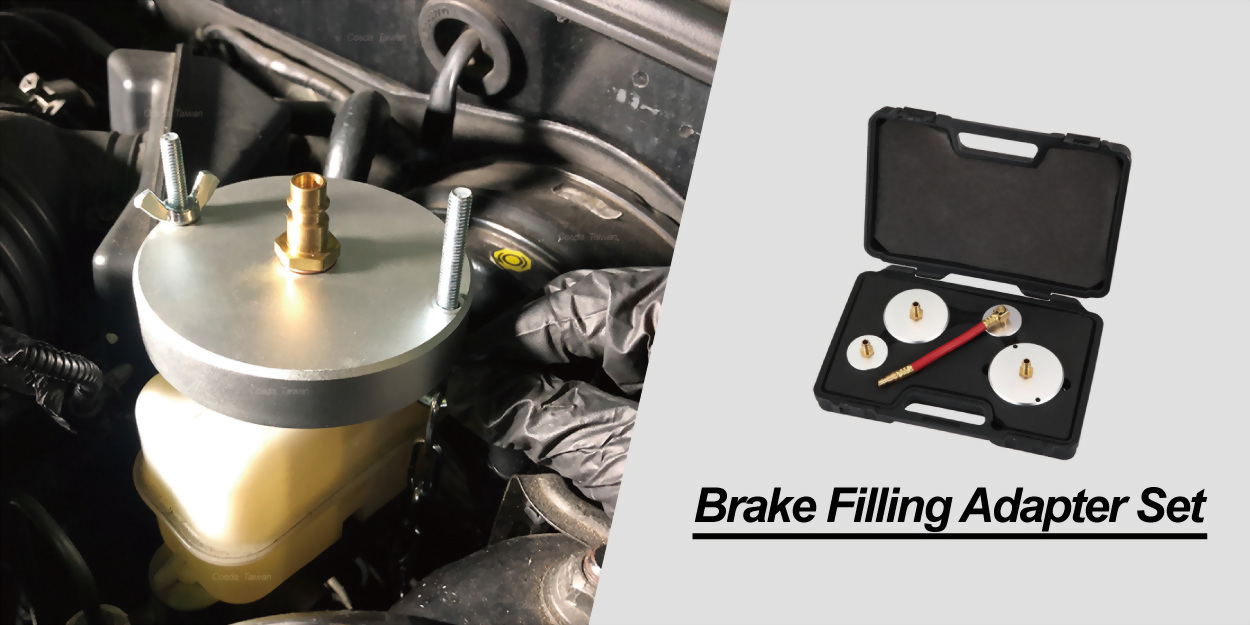

Brake Filling Adapter Set (4 pcs)

• Includes 3 specific adapters and 1 universal adapter with a fastening chain

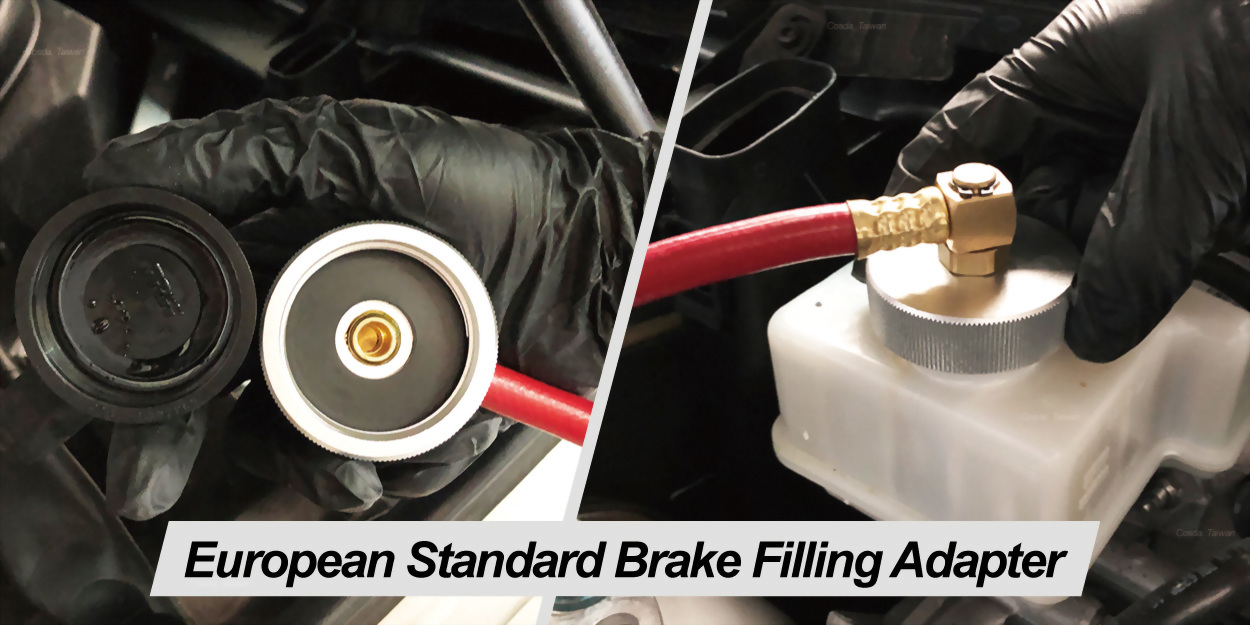

• E20 adapter with a 90° extension hose and free rotation feature provids unrestricted access to

limited spaces

• Uses standard European shop air connector for easy connectability

• Operation pressure up to 1.5 bar / 21.75 psi

Subaru 26401AA354, Volvo 3345685, MR527470, MR475973, 4625A161, MR475284, MR527468, MB858527

46010-4EA0A, 46010-1KW0B, 1844832, 1106259, 1835440, 1508077, BPYL4355ZA, DR61-43-55Y, 13338444, 13286455, 6N1611349B, 7P0611349, 5Q0-611-349-A, 7D0611349, 7L0611349, 1K1611349C, 31317214, 9438753

What is brake pressure bleeding?

Brake pressure bleeding is a method used to remove air from a vehicle's brake system, ensuring that the brakes operate effectively. It involves using pressure to force brake fluid through the brake lines, which pushes out any trapped air bubbles. Air in the brake system can cause a spongy brake pedal and reduce braking efficiency, so bleeding the brakes is a crucial maintenance task.

How Brake Pressure Bleeding Works:

1. Pressurizing the System: A brake pressure bleeder, a specialized tool, is connected to the master cylinder reservoir. The bleeder pressurizes the brake fluid in the system.

2. Opening the Bleeder Valves: Each brake caliper or wheel cylinder has a bleeder valve. With the system pressurized, these valves are opened one at a time, starting with the brake farthest from the master cylinder and moving closer.

3. Expelling Air: As each valve is opened, brake fluid is forced through the brake lines and out of the valve, carrying any trapped air with it. The process continues until a steady stream of fluid, free of air bubbles, flows from the valve.

4. Closing the Valves: Once the air is removed, the bleeder valve is closed, and the process is repeated for each brake.

Advantages of Brake Pressure Bleeding:

- Efficiency: The process is generally faster and more thorough than manual brake bleeding.

- Consistency: It ensures a more consistent removal of air from the system.

- Ease of Use: It can often be done by a single person, as opposed to traditional methods that may require two people.

When to Use:

Brake pressure bleeding is often used after replacing brake components, such as brake lines, calipers, or master cylinders, or when air has entered the brake system for any reason.

Why is it necessary to remove air from brake fluid?

Removing air from brake fluid is crucial for the proper functioning of a vehicle's braking system. Here’s why:

1. Prevents a Spongy Brake Pedal:

- Air Compressibility: Brake fluid is incompressible, meaning it transmits force efficiently through the brake lines to the brake calipers or wheel cylinders. However, air is compressible. If air is present in the brake lines, it compresses when the brake pedal is pressed, resulting in a soft or spongy pedal feel. This reduces the effectiveness of the braking system.

2. Ensures Consistent Braking Force:

- Inconsistent Pressure: Air pockets in the brake system can cause inconsistent hydraulic pressure when braking. This can lead to uneven braking force applied to the wheels, which may result in unpredictable braking performance, increasing the risk of accidents.

3. Maintains Proper Brake Functionality:

- Full Brake Engagement: For brakes to work effectively, the hydraulic pressure must be evenly distributed throughout the system. Air in the system disrupts this balance, potentially leading to situations where the brakes don’t fully engage when needed, especially during sudden stops.

4. Safety Concerns:

- Reduced Braking Efficiency: Any delay or reduction in braking force due to air in the brake lines can increase stopping distances, particularly in emergency situations, endangering the driver, passengers, and others on the road.

5. Prevents Damage to Brake Components:

- Overheating: Trapped air can cause brake components to overheat because of the increased pedal travel and the need to apply more pressure to achieve the desired braking effect. This can lead to premature wear or failure of brake components.

By bleeding the brakes and removing air from the brake fluid, you ensure that the braking system operates with maximum efficiency and safety.

531-2B500, 58531-07000, 58531-07000, 20760280, Dorman 42042, 46020AL500, 46020-EA20A, 46020-AL600, 46020-4CU0A, 46020-6N000, BRFC-1, 4625A380, 4625A385, ZZD1-43-990

| Package | Blow molded case (black) | |

| Packing | 10 sets in a master carton | |

| Weight per set | 1.1 kg | 2.3 lbs |

| Net weight per carton | 10.5 kg | 23.1 lbs |

| Gross weight per carton | 11.5 kg | 25.3 lbs |

| Size per set | 35.0 × 24.0 × 8.6 cm | 13.8 × 9.4 × 3.4 inch |

| Size per carton | 48.8 × 37.3 × 54.2 cm | 19.2 × 14.7 × 21.3 inch |

| Volume per carton | 0.1 CBM | 3.5 CUFT |

| Case label size | 20.1 × 7.1 cm | 7.9 × 2.7 inch |

| No. | Image | Cosda No. | Description | |

|---|---|---|---|---|

| 1 |  |

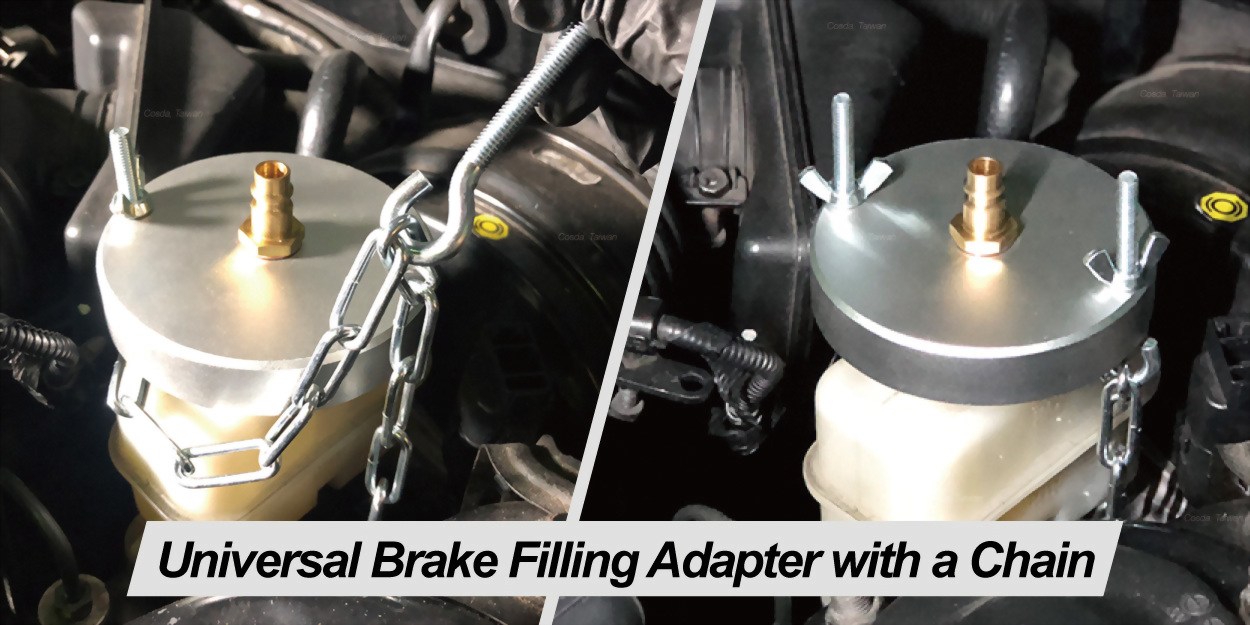

SD-1201A-1 | Universal Brake Adapter with Chain | More |

|

- Specifications

|

||||

|

|

||||

| 2 |  |

SD-1201A-2 | Brake Adapter M79.5 x P3.0 | More |

|

- Specifications

|

||||

|

|

||||

| 3 |  |

SD-1201A-3 | Brake Adapter M33 with 3 Pins | More |

|

- Specifications

|

||||

|

|

||||

| 4 |  |

SD-1201A-4 | Brake Adapter Standard European Type | More |

|

- Specifications

|

||||

| Suggested HS code |

82055990909 |

| MOQ with laser marking | 20 sets |

| MOQ without laser marking | 10 sets |

| Laser marking cost | + TWD 3 on each part |