Exhaust Hanger Removal Pliers

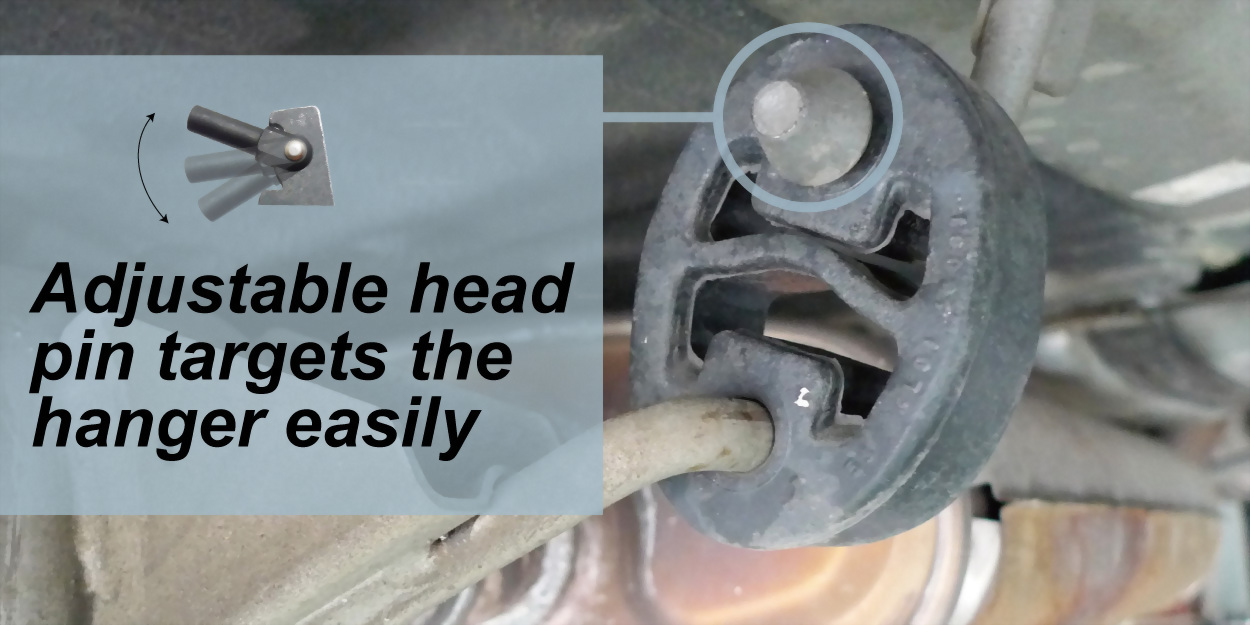

• Adjustable head pin provides a wide application

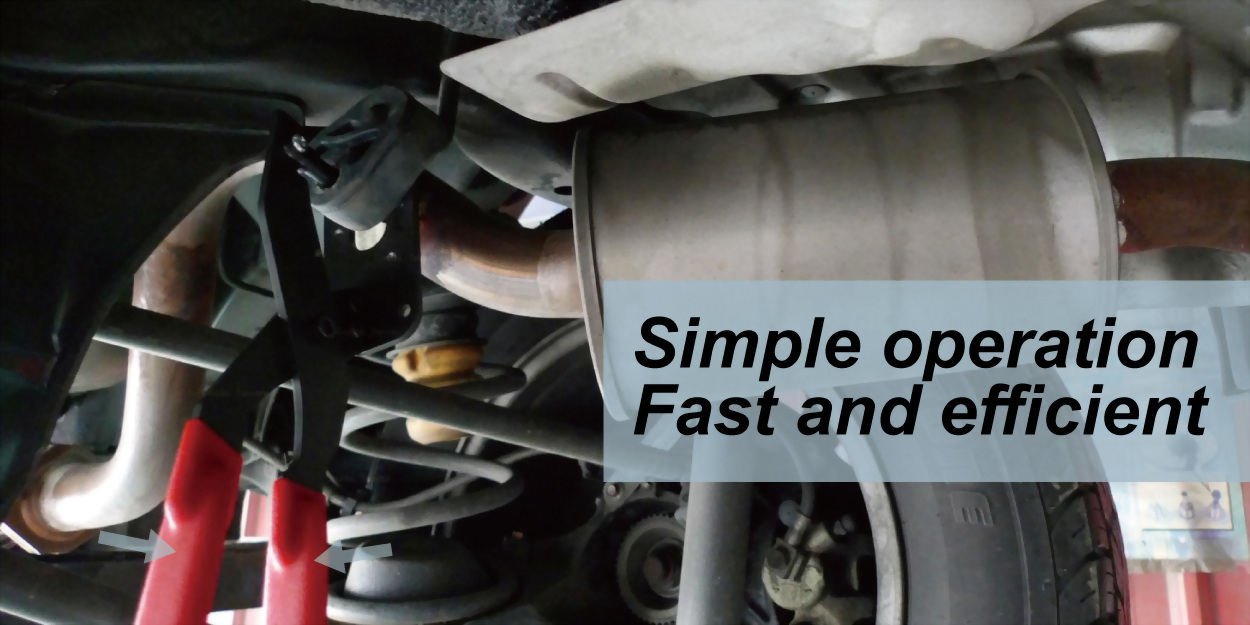

• Large body length 367 mm / 14.5 in offers extra leverage for an effortless operation

Why is there a rubber part that hangs the exhaust pipes under the car?

The rubber parts that hang the exhaust pipes under a car are called exhaust hangers or exhaust mounts. They serve several important purposes:

1. Vibration Dampening: The engine and exhaust system generate vibrations while the vehicle is running. Rubber hangers help absorb and dampen these vibrations, preventing them from being transferred to the vehicle's body, which would result in noise and discomfort for the passengers.

2. Flexibility and Movement: The exhaust system expands and contracts due to temperature changes as it heats up and cools down. The rubber hangers provide the necessary flexibility to accommodate this thermal expansion and contraction without causing damage to the exhaust system or other components.

3. Support and Stability: The rubber hangers help support the weight of the exhaust system and keep it securely in place. They ensure that the exhaust pipes and mufflers are properly aligned and do not sag or come into contact with other parts of the vehicle.

4. Protection Against Road Shock: Driving over rough roads or bumps can cause jolts and impacts that could damage the exhaust system if it were rigidly mounted. The rubber hangers act as a cushion, absorbing these shocks and protecting the exhaust components from damage.

5. Noise Reduction: By isolating the exhaust system from the vehicle's body, the rubber hangers help reduce the transmission of noise and vibrations into the cabin, contributing to a quieter and more comfortable ride.

Regular inspection and replacement of worn or damaged rubber hangers are important to maintain the proper function of the exhaust system and to prevent issues such as excessive noise, vibrations, or exhaust leaks.

Does that rubber hanger need to be replaced regularly?

Yes, the rubber hangers for the exhaust system should be inspected regularly and replaced if necessary. Here are some reasons and signs indicating when they might need replacement:

Reasons for Replacement

1. Wear and Tear: Over time, rubber components naturally degrade due to constant exposure to heat, cold, moisture, and road debris.

2. Cracking and Dry Rot: Rubber can dry out, crack, and become brittle, leading to potential failure.

3. Stretching: Continuous exposure to the weight and movement of the exhaust system can cause the hangers to stretch and lose their effectiveness.

4. Damage: Physical damage from road debris or impacts can compromise the integrity of the hangers.

Signs That Replacement is Needed

1. Excessive Movement: If the exhaust system moves excessively or sags, it can indicate that the rubber hangers are worn out or broken.

2. Rattling or Clunking Noises: Unusual noises coming from under the car, especially when driving over bumps or uneven surfaces, can suggest that the exhaust hangers are failing.

3. Visual Inspection: During routine maintenance, check the condition of the rubber hangers. Look for signs of cracking, tearing, or significant wear.

4. Exhaust System Misalignment: If the exhaust pipes or mufflers appear misaligned or are closer to the ground than usual, the hangers might need to be replaced.

Maintenance Tips

- Regular Inspections: Check the rubber hangers during routine vehicle maintenance, especially if you notice any unusual noises or vibrations. If this part needs to be replaced, use Cosda’s SD-1120 for fast removal of the exhaust rubber hanger part.

- Replacement Intervals: While there is no set interval for replacing exhaust hangers, it's generally a good idea to inspect them every time the exhaust system is serviced.

- Quality Parts: When replacing rubber hangers, use high-quality parts designed for your specific vehicle model to ensure proper fit and durability.

By keeping an eye on the condition of the rubber hangers and replacing them as needed, you can help maintain the integrity of the exhaust system and prevent potential issues.

| Package | Sliding card + blisters | |

| Packing | 10 sets in an inner carton, 20 sets in a master carton | |

| Weight per set | 825 g | 1.8 lbs |

| Net weight per carton | 16.5 kg | 36.5 lbs |

| Gross weight per carton | 17.5 kg | 38.5 lbs |

| Size per set | 45.9 × 13.0 × 6.0 cm | 18.1 × 5.1 × 2.4 inch |

| Size per carton | 37.8 × 33.3 × 50.3 cm | 14.9 × 13.1 × 19.8 inch |

| Volume per carton | 0.063 CBM | 2.2 CUFT |

| Suggested HS code |

82041100004 |

| MOQ with laser marking | 40 sets |

| MOQ without laser marking | 20 sets |

| Laser marking cost | + TWD 4 |

| Not for sale in | Canada |

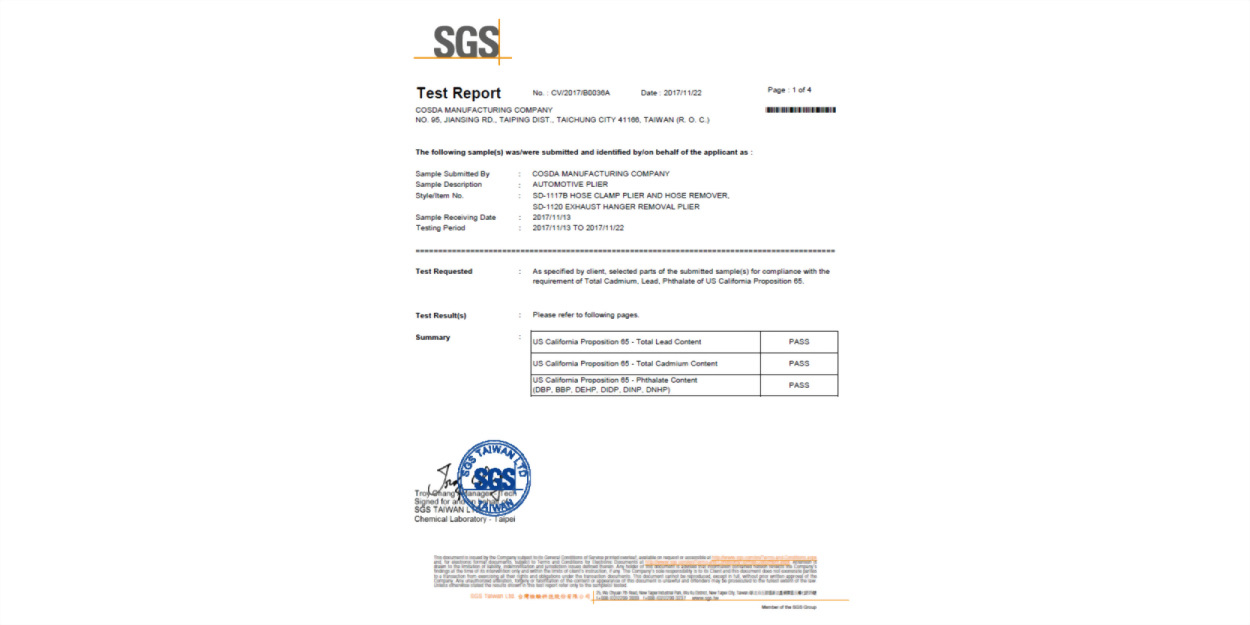

This product has passed the test for the compliance with the requirement of total Cadmium, Lead, Phthalate as specified in the US California Proposition 65.